What Is Timing In A Car

Alright, let's dive into the fascinating world of engine timing! Whether you're troubleshooting a rough idle, planning a performance upgrade, or simply want a deeper understanding of how your internal combustion engine works, knowing the ins and outs of timing is crucial. This isn't just about setting a distributor; it's about understanding the choreographed dance of valves, pistons, and spark that makes your car go.

Purpose: Why Understanding Timing Matters

Think of engine timing as the conductor of an orchestra. If one instrument is out of sync, the whole performance suffers. Similarly, if your engine's timing is off, you'll experience a host of problems, ranging from poor fuel economy and reduced power to engine knocking and even catastrophic damage. Understanding timing allows you to:

- Diagnose and repair running issues: Rough idling, misfires, hesitation, and poor acceleration are often symptoms of timing problems.

- Perform routine maintenance: Certain timing components require periodic inspection and replacement, like timing belts or chains.

- Optimize engine performance: Adjusting timing can unlock hidden horsepower and improve fuel efficiency, especially after modifications.

- Safely modify your engine: Changing camshafts, cylinder heads, or other components requires precise timing adjustments to avoid engine damage.

By grasping the concepts we'll cover, you'll be better equipped to tackle these tasks and communicate effectively with your mechanic.

Key Specs and Main Parts

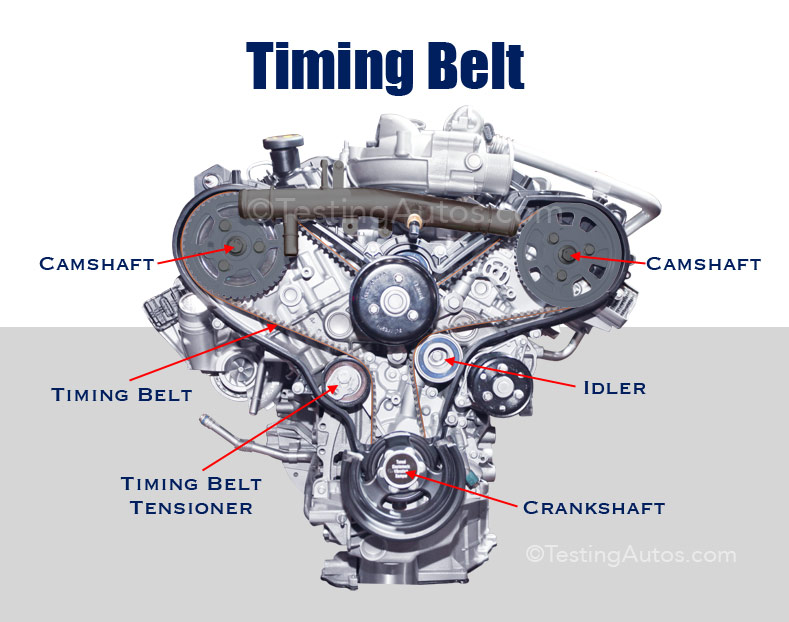

Let's break down the key players and their specifications. The core components involved in timing are:

- Crankshaft: The crankshaft is the backbone of the engine, converting reciprocating motion (from the pistons) into rotational motion. Its position is the primary reference point for timing.

- Camshaft(s): The camshaft controls the opening and closing of the intake and exhaust valves. Its lobes push on lifters (or directly on valves in some engines) to actuate the valves at specific times. Many engines now have multiple camshafts – DOHC (Dual Overhead Camshaft) – often with variable valve timing (VVT).

- Timing Belt/Chain: The timing belt (or chain) connects the crankshaft and camshaft(s), ensuring they rotate in precise synchronization. A worn or broken timing belt/chain can lead to severe engine damage.

- Distributor (Older Engines): In older engines, the distributor is responsible for distributing high-voltage electricity to the spark plugs in the correct firing order and at the correct time. It's driven by either the camshaft or the crankshaft.

- Ignition System (Modern Engines): Modern engines use a computer-controlled ignition system, which includes a crankshaft position sensor (CKP) and a camshaft position sensor (CMP). These sensors provide information to the engine control unit (ECU) about the position of the crankshaft and camshaft, allowing the ECU to precisely control ignition timing. Coil-on-plug (COP) systems are now common, eliminating the need for a distributor.

- Valves: Intake valves and exhaust valves, precisely timed to open and close for optimal combustion.

- ECU (Engine Control Unit): The 'brain' of the engine, controls fuel injection, ignition timing, and many other functions based on sensor inputs.

Key Specifications:

- Ignition Timing: Measured in degrees Before Top Dead Center (BTDC) or After Top Dead Center (ATDC). This is the point at which the spark plug fires in relation to the piston's position. Base timing is the initial timing setting before the ECU makes adjustments.

- Valve Timing: Expressed in degrees of crankshaft rotation. This specifies when the intake and exhaust valves open and close in relation to the piston's position. Key specs include intake valve opening (IVO), intake valve closing (IVC), exhaust valve opening (EVO), and exhaust valve closing (EVC). Valve overlap is the period when both intake and exhaust valves are open simultaneously.

- Firing Order: The sequence in which the cylinders fire. This is critical for balanced engine operation.

How It Works

The engine cycle consists of four strokes: intake, compression, combustion (power), and exhaust. Timing dictates when each of these strokes begins and ends.

- Intake: The intake valve opens, and the piston moves down, drawing air and fuel into the cylinder.

- Compression: Both intake and exhaust valves are closed, and the piston moves up, compressing the air-fuel mixture.

- Combustion: As the piston reaches the top of the compression stroke (or slightly before, depending on ignition timing), the spark plug ignites the air-fuel mixture, creating a powerful explosion that forces the piston down.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the spent exhaust gases out of the cylinder.

The camshaft(s) control the valve timing, and the ignition system controls the spark timing. These systems must be precisely synchronized to ensure optimal engine performance. Modern engines use sophisticated sensors and ECUs to dynamically adjust timing based on various factors, such as engine load, speed, and temperature. Variable valve timing (VVT) systems can further optimize engine performance by altering valve timing based on operating conditions.

Real-World Use – Basic Troubleshooting Tips

Here are a few common symptoms and potential causes related to timing issues:

- Rough Idling/Misfires: Could indicate incorrect ignition timing, a vacuum leak affecting timing advance, or a faulty crankshaft/camshaft position sensor.

- Poor Acceleration/Lack of Power: May be due to retarded ignition timing, a worn timing belt/chain (slipping), or a clogged catalytic converter.

- Engine Knocking/Pinging: Often caused by advanced ignition timing, lean air-fuel mixture, or excessive carbon buildup in the cylinders.

- Difficulty Starting: Can be related to incorrect base timing or a faulty crankshaft position sensor.

Troubleshooting Steps:

- Check for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to check for any error codes related to timing or sensors.

- Inspect Timing Belt/Chain: Look for signs of wear, cracks, or looseness. Ensure the timing marks are aligned correctly when the engine is at Top Dead Center (TDC).

- Verify Ignition Timing: Use a timing light (for older engines) or a scan tool (for newer engines) to verify the ignition timing.

- Check Sensors: Inspect the crankshaft and camshaft position sensors for damage or contamination. Test their output signals using a multimeter or oscilloscope.

Safety – Highlight Risky Components

Working on engine timing can be risky, especially when dealing with these components:

- Timing Belt/Chain: If the timing belt/chain breaks while the engine is running, it can cause catastrophic engine damage, especially in interference engines (where the valves and pistons can collide). Always disconnect the battery before working on the timing belt/chain.

- High-Voltage Ignition System: The ignition system generates extremely high voltages (tens of thousands of volts). Avoid touching any ignition components while the engine is running. Always disconnect the battery before working on the ignition system.

- Rotating Engine Components: Keep your hands and tools clear of rotating engine components, such as the crankshaft pulley, camshaft sprockets, and belts. Ensure the engine is off and cool before working on it.

- Fuel System: Incorrect timing adjustments can affect the air-fuel mixture, potentially leading to a lean condition (which can cause engine damage) or a rich condition (which can damage the catalytic converter). Take extreme care when making timing adjustments, and monitor the air-fuel ratio using a scan tool or wideband O2 sensor.

Remember, when in doubt, consult a qualified mechanic. Improper timing can lead to significant engine damage.

This detailed explanation should provide a solid foundation for understanding engine timing. Remember to consult your vehicle's service manual for specific procedures and specifications.

We have a detailed timing diagram available for download. This diagram visually represents the relationships between the crankshaft, camshaft(s), valves, and ignition system, making it easier to understand the timing process. This can be a very helpful tool when trying to learn or troubleshoot your car's timing system.