What Is Transmission In A Car

So, you want to dive deeper into the inner workings of your car's transmission? Excellent! Understanding the transmission is crucial, whether you're tackling basic maintenance, diagnosing a nagging problem, or even planning a performance upgrade. This guide provides a detailed look at transmissions, designed for the experienced DIYer who isn't afraid to get their hands dirty.

Why This Matters

Why bother understanding your transmission? Simple: knowledge is power. A solid grasp of transmission principles allows you to:

- Troubleshoot effectively: Knowing how the transmission *should* work makes it easier to identify what's going wrong.

- Perform maintenance intelligently: You'll understand the importance of fluid changes, filter replacements, and other preventative measures.

- Make informed decisions about repairs: When your mechanic explains the problem, you'll be able to understand the diagnosis and evaluate the proposed solution.

- Explore performance upgrades: Thinking about a shift kit or a different gear ratio? Understanding the impact on transmission operation is essential.

Let's face it, transmissions can seem like a black box. But they don't have to be. Let's crack it open and see what's inside.

Key Specs and Main Parts

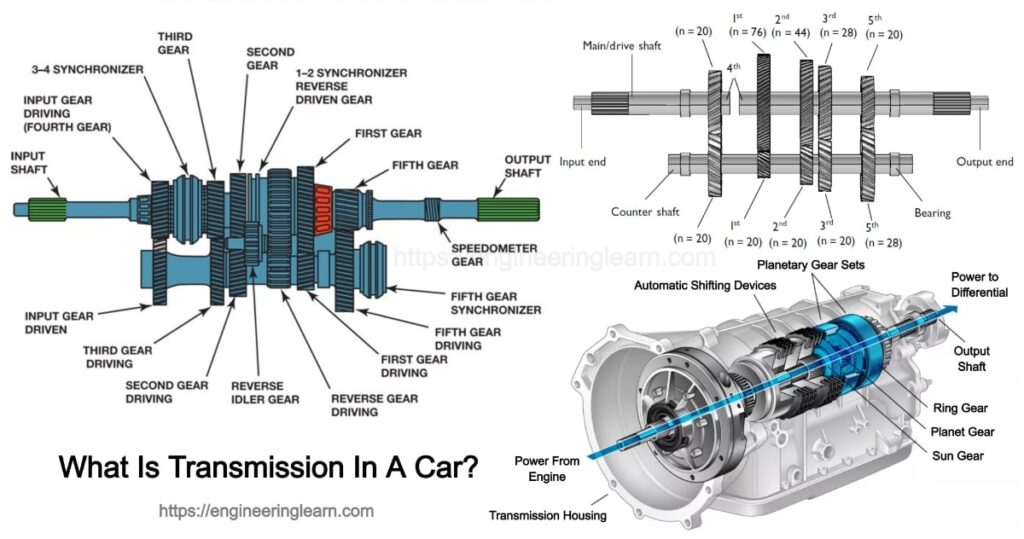

The primary function of the transmission is to transfer the power from the engine to the wheels, while also allowing the engine to operate within its optimal RPM range regardless of the vehicle's speed. It does this by varying the gear ratio – the relationship between the engine's crankshaft rotations and the wheels' rotations.

There are two main types of transmissions: manual and automatic. Let's break down the components of each:

Manual Transmission

Key components:

- Input Shaft: Connected to the engine's crankshaft via the clutch. It spins at the same speed as the engine when the clutch is engaged.

- Output Shaft: Connected to the driveshaft, which transmits power to the wheels.

- Gears: Multiple sets of gears with different sizes, providing different gear ratios. These are usually arranged in a series on the input and output shafts.

- Synchronizers (Synchros): These ingenious devices match the speeds of the gears before they engage, preventing grinding and allowing for smooth shifts.

- Shift Forks: Move the synchronizers and engage the appropriate gear.

- Shift Linkage: Connects the shift lever in the cabin to the shift forks within the transmission.

- Clutch: A friction disc that connects and disconnects the engine from the transmission, allowing the driver to change gears.

- Flywheel: A heavy disc connected to the engine that provides inertia and a surface for the clutch to grip.

Automatic Transmission

Automatic transmissions are far more complex than manual ones, relying on hydraulics and electronics to shift gears automatically.

- Torque Converter: Replaces the clutch. It uses fluid to transmit power from the engine to the transmission, providing torque multiplication at low speeds.

- Planetary Gear Sets: Complex arrangements of gears that provide different gear ratios.

- Clutches and Bands: Used to engage and disengage different parts of the planetary gear sets, changing the gear ratio.

- Valve Body: The hydraulic control center of the transmission. It contains valves that direct fluid to the appropriate clutches and bands based on engine speed, load, and driver input.

- Transmission Control Module (TCM): An electronic control unit that monitors various sensors and controls the valve body.

- Sensors: Speed sensors, temperature sensors, and pressure sensors provide information to the TCM.

- Transmission Fluid: A specialized fluid that lubricates, cools, and transmits hydraulic pressure.

How It Works

Manual Transmission Operation

In a manual transmission, the driver selects the desired gear using the shift lever. This movement actuates the shift linkage, which moves the shift forks. The shift forks then engage the appropriate synchronizer, which matches the speeds of the selected gear. Once the speeds are matched, the synchronizer engages the gear, connecting the input and output shafts through the selected gear ratio.

The clutch is crucial. When you press the clutch pedal, it disengages the engine from the transmission, allowing you to shift gears without damaging the components. Releasing the clutch re-engages the engine, transferring power to the wheels.

Automatic Transmission Operation

Automatic transmissions use a torque converter instead of a clutch. The torque converter consists of three main components: an impeller (connected to the engine), a turbine (connected to the transmission), and a stator. The impeller spins, pumping fluid towards the turbine, which causes it to spin as well, thus transferring power. The stator redirects the fluid flow, increasing torque at low speeds.

The valve body is the heart of the automatic transmission. It uses hydraulic pressure to control the clutches and bands that engage and disengage the planetary gear sets. The TCM monitors various sensors, such as engine speed, vehicle speed, and throttle position, and uses this information to determine the optimal gear ratio. It then signals the valve body to shift to the appropriate gear.

Real-World Use – Basic Troubleshooting Tips

Here are some common transmission problems and possible causes:

- Manual Transmission: Difficulty Shifting: Could be caused by a worn clutch, damaged synchronizers, or a problem with the shift linkage.

- Manual Transmission: Grinding During Shifts: Usually indicates worn synchronizers.

- Automatic Transmission: Slipping Gears: Could be caused by low transmission fluid, worn clutches or bands, or a malfunctioning valve body.

- Automatic Transmission: Harsh Shifting: Could be caused by low transmission fluid, a malfunctioning valve body, or a problem with the TCM.

- Leaking Fluid: Indicates a damaged seal or gasket. Transmission fluid is typically red or brown and has a distinct odor.

- Unusual Noises: Whining, clunking, or buzzing sounds can indicate various internal problems.

Troubleshooting Tip: Always check the transmission fluid level first. Low fluid is a common cause of many transmission problems.

Safety

Working on a transmission can be dangerous. Here are some safety precautions:

- Support the Vehicle Properly: Never work under a vehicle supported only by a jack. Use jack stands.

- Wear Safety Glasses: Protect your eyes from flying debris.

- Handle Transmission Fluid Carefully: Transmission fluid can be hot and slippery. Wear gloves.

- Be Aware of Springs and Pressure: Some components, like the valve body, contain springs and pressurized fluid. Disassemble them carefully and refer to a service manual.

- Dispose of Used Fluid Properly: Transmission fluid is hazardous waste and must be disposed of according to local regulations.

Risky Components: The torque converter in an automatic transmission can be very heavy and awkward to handle. The valve body contains delicate components and requires careful handling and reassembly. Always consult a service manual before disassembling any transmission component.

Conclusion

Understanding your car's transmission is a journey, not a destination. The more you learn, the better equipped you'll be to keep your vehicle running smoothly. Remember to consult your vehicle's service manual for specific instructions and torque specifications. Happy wrenching!