What Is Transmission Of A Car

Alright folks, let's dive into the heart of your car's drivetrain – the transmission. Whether you're planning a performance upgrade, tackling a repair, or just want a deeper understanding of how your vehicle works, grasping the intricacies of the transmission is crucial. This article is designed to give you, the experienced DIYer, the technical know-how you need. We'll go over everything from the basic purpose and components to troubleshooting and safety considerations.

Purpose of Understanding the Transmission

Why bother getting familiar with the transmission diagram and its inner workings? Several reasons. First, it's essential for accurate diagnostics. Knowing how the system should operate helps you pinpoint problems when things go wrong. Second, it aids in proper repairs. Blindly replacing parts is costly and often ineffective. A solid understanding allows for targeted fixes. Third, it empowers you to make informed decisions about upgrades. Are you considering a different gear ratio? A torque converter upgrade? Knowing the system's limitations and capabilities is key. Finally, it simply boosts your overall mechanical aptitude, making you a more capable and confident car enthusiast.

Key Specs and Main Parts

The transmission's primary job is to manage the engine's power output and deliver it efficiently to the wheels. It does this by varying the gear ratio, trading torque for speed (or vice versa) as needed. Key specifications you'll encounter include the number of gears (e.g., 5-speed, 6-speed, 8-speed), the gear ratios themselves (expressed as a ratio, e.g., 4.10:1), and the torque capacity of the transmission (the maximum amount of torque it can handle without damage).

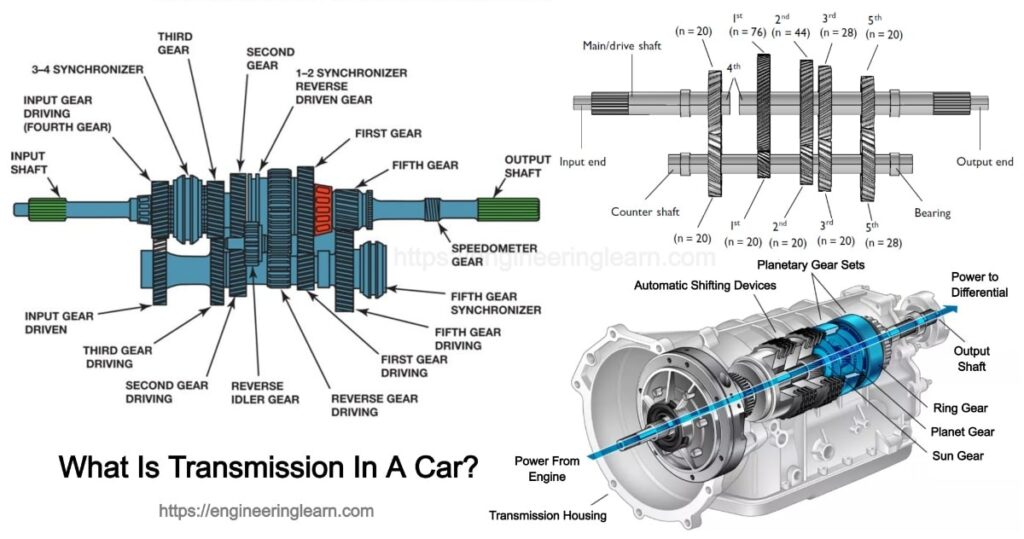

Here's a breakdown of the main components you'll typically find in a manual or automatic transmission:

Manual Transmission Parts:

- Input Shaft: Receives power from the engine via the clutch.

- Main Shaft (Output Shaft): Delivers power to the driveshaft and ultimately the wheels.

- Countershaft: An intermediary shaft with gears that mesh with the main shaft gears.

- Gears: The heart of the transmission, providing different gear ratios. Typically spur gears or helical gears (for quieter operation).

- Synchronizers: Match the speed of the gears before engagement, preventing grinding.

- Shift Forks: Move the synchronizers to engage different gears.

- Shift Linkage: Connects the shift lever in the cabin to the shift forks.

- Clutch: Disconnects the engine from the transmission, allowing for gear changes.

- Pressure Plate: Applies pressure to the clutch disc, clamping it against the flywheel.

- Throwout Bearing (Release Bearing): Releases the pressure plate, disengaging the clutch.

Automatic Transmission Parts:

- Torque Converter: Replaces the clutch in a manual transmission. It uses fluid to transmit power from the engine to the transmission.

- Planetary Gear Sets: Complex arrangements of gears that provide different gear ratios. Consist of sun gear, planet gears, ring gear, and carrier.

- Clutches and Bands: Engage and disengage different planetary gear sets to change gears. Hydraulically actuated.

- Valve Body: The hydraulic control center of the transmission, directing fluid to the appropriate clutches and bands based on driver input and vehicle conditions.

- Transmission Control Module (TCM): The electronic brain of the transmission, controlling the valve body and other functions.

- Pump: Provides hydraulic pressure to operate the clutches, bands, and valve body.

- Governor: (In older automatics) A speed-sensitive device that helps regulate shift points.

Understanding Transmission Diagrams: Symbols and Conventions

Transmission diagrams, like all technical schematics, use symbols to represent different components and their connections. Here's a general guide to common symbols:

- Solid Lines: Typically represent mechanical connections or hydraulic lines. Thicker lines often indicate main power flow or high-pressure lines.

- Dashed Lines: Often represent control signals, vacuum lines, or low-pressure hydraulic lines.

- Circles: Can represent gears, bearings, or shafts depending on the context.

- Rectangles: Often represent electronic components like sensors, solenoids, or the TCM.

- Triangles: Can represent valves or pumps in hydraulic diagrams.

- Springs: Represented by a coiled line, indicating a spring-loaded component.

- Ground Symbol: Indicates a connection to the vehicle's chassis ground (electrical).

Color coding, if present, can provide further information. For example, in hydraulic diagrams, different colors might represent different pressure levels or fluid types. Always refer to the diagram's legend for specific symbol and color definitions. Note that diagrams vary widely based on the manufacturer and model of the transmission, so a generic guide will only take you so far.

How It Works: The Flow of Power

Let's look at a simplified explanation of how power flows through both types of transmission.

Manual Transmission Operation:

- The engine's power is transferred to the transmission input shaft via the clutch.

- The input shaft turns the countershaft.

- Gears on the countershaft are constantly meshed with gears on the main shaft. However, the main shaft gears are not directly connected until a gear is selected.

- When you select a gear, the shift linkage moves a shift fork, which engages a synchronizer.

- The synchronizer matches the speed of the chosen gear on the main shaft to the speed of the countershaft gear.

- Once synchronized, the synchronizer locks the main shaft gear to the main shaft, transmitting power.

- The main shaft then delivers power to the driveshaft and wheels.

Automatic Transmission Operation:

- The engine's power is transferred to the torque converter, which acts as a fluid coupling.

- The torque converter multiplies torque, especially at low engine speeds.

- The output of the torque converter drives the planetary gear sets.

- The valve body, controlled by the TCM, directs hydraulic fluid to engage specific clutches and bands.

- Engaging different combinations of clutches and bands locks different components of the planetary gear sets, resulting in different gear ratios.

- The selected gear ratio is then delivered to the output shaft, driveshaft, and wheels.

Real-World Use: Basic Troubleshooting Tips

Here are some common transmission problems and potential causes, along with basic troubleshooting steps:

- Slipping Gears: The transmission shifts out of gear unexpectedly. Possible causes: low fluid level, worn clutches/bands (automatic), worn synchronizers (manual), faulty valve body (automatic). Check fluid level first. If low, top it off and check for leaks. If fluid is burnt or contaminated, a more serious problem is likely.

- Rough Shifting: Hard or jerky shifts. Possible causes: low fluid level (automatic), worn synchronizers (manual), faulty shift linkage, valve body issues (automatic). Inspect shift linkage for wear or damage. Consider a transmission fluid flush (automatic) if the fluid is old or contaminated.

- Grinding During Shifting (Manual): A grinding noise when shifting gears. Likely cause: worn synchronizers. This usually requires transmission disassembly and repair.

- Transmission Noise: Unusual whining, humming, or clunking noises. Possible causes: low fluid level, worn bearings, damaged gears. Try to pinpoint the source of the noise. Check fluid level and condition.

- Failure to Shift (Automatic): The transmission does not shift at all or gets stuck in one gear. Possible causes: Faulty TCM, valve body issues, internal damage. Check for diagnostic trouble codes (DTCs) using an OBD-II scanner.

Remember: These are just basic troubleshooting tips. More complex issues require specialized tools and knowledge.

Safety: Handle with Care!

Working on transmissions involves several safety hazards. Never work under a vehicle supported only by a jack. Always use jack stands. Transmission fluid can be hot, so allow the transmission to cool before draining. Be extremely careful when working with compressed air, especially when disassembling automatic transmissions, as some components are under spring pressure. Wear safety glasses and gloves to protect yourself from fluids and debris. Finally, be aware that automatic transmissions contain high-pressure hydraulic systems. Improper disassembly can result in serious injury.

The torque converter contains a significant amount of oil. Take extreme care when removing this part from an automatic transmission. It is heavy, and the oil will spill if not handled correctly.

Always disconnect the negative battery cable before working on any electrical components of the transmission, such as sensors or solenoids.

Understanding your car’s transmission is a challenging but rewarding endeavor. With this knowledge, you’ll be better equipped to diagnose issues, perform basic maintenance, and even tackle more advanced modifications.

We have a detailed transmission diagram that corresponds to this article, that you can download and inspect, which will help you with your repairs and learning. Please send a message with subject line "Transmission Diagram Request" to email address "[email protected]", and we'll send you the file.