What Is Turbo Engine In Cars

So, you're keen to dive deeper into the world of turbo engines, huh? Smart move! Understanding turbocharging is crucial whether you're tackling DIY repairs, planning performance upgrades, or simply want to be a more informed car owner. This article will give you a solid foundation on turbo engine technology, focusing on its components, function, and potential pitfalls.

Understanding the Turbocharged Engine

At its core, a turbocharger is an air compressor that forces more air into the engine's cylinders. More air allows for more fuel to be burned, resulting in a significant power increase without increasing the engine's displacement (size). This is especially important for achieving high performance in smaller, more fuel-efficient engines. Think of it like giving your engine a bigger set of lungs!

Key Specs and Main Parts

Let's break down the key components of a typical turbo system. You'll often find variations, but these are the core elements:

- Turbocharger Housing (Turbine and Compressor): This is the heart of the system. It consists of two connected housings. The turbine housing contains a turbine wheel that spins as exhaust gases pass through it. The compressor housing contains a compressor wheel, connected to the turbine wheel by a shaft. As the turbine spins, the compressor also spins, drawing in and compressing intake air.

- Turbine Wheel: A precisely engineered bladed wheel that is spun by the force of exhaust gases. The faster it spins, the more air the compressor pumps into the engine.

- Compressor Wheel: Also bladed, this wheel compresses and pumps intake air into the engine's intake manifold. Material is very important and it needs to withstand extreme stresses and high speeds.

- Shaft: A robust shaft that physically connects the turbine and compressor wheels. It spins at incredibly high speeds, often exceeding 100,000 RPM.

- Wastegate: A valve that allows some exhaust gas to bypass the turbine wheel, controlling the boost pressure (the amount of pressure the turbocharger is adding to the intake air). This prevents over-boosting, which can damage the engine.

- Blow-Off Valve (BOV) / Diverter Valve: Releases excess pressure in the intake system when the throttle is closed. This prevents compressor surge, a phenomenon that can damage the turbocharger. Diverter valves recirculate the air back into the intake, while blow-off valves vent it to the atmosphere (creating that characteristic "whoosh" sound).

- Intercooler: Cools the compressed air from the turbocharger before it enters the engine. Colder air is denser, containing more oxygen, which further improves combustion and power output. This helps avoid detonation or "knock."

- Oil Feed and Drain Lines: These lines provide lubrication and cooling to the turbocharger's bearings. Proper lubrication is crucial for the turbocharger's longevity.

Common Turbo Specs:

- A/R Ratio: This refers to the area-to-radius ratio of the turbine housing. A smaller A/R ratio improves low-end torque and quicker spool-up (how quickly the turbocharger starts producing boost), while a larger A/R ratio is better for high-end power.

- Boost Pressure (PSI or Bar): This is the amount of pressure, above atmospheric pressure, that the turbocharger is adding to the intake air.

- Compressor Map: A chart that shows the turbocharger's performance characteristics, including airflow and pressure ratios, at different RPMs. This is useful for selecting the right turbocharger for a specific engine and application.

How It Works

The turbocharger's operation is a clever use of otherwise wasted energy. Here's the breakdown:

- Exhaust Gas Flow: Exhaust gases from the engine's cylinders are directed into the turbine housing.

- Turbine Spin: The force of the exhaust gases spins the turbine wheel at very high speeds.

- Compressor Activation: The turbine wheel is connected to the compressor wheel by a shaft. As the turbine spins, it also forces the compressor wheel to spin.

- Air Compression: The compressor wheel draws in fresh air from the intake and compresses it, increasing its density and pressure.

- Air Cooling (Optional): The compressed air, now heated by the compression process, is passed through an intercooler to lower its temperature.

- Intake Manifold Delivery: The cooled, compressed air is then delivered to the engine's intake manifold.

- Combustion: The engine's cylinders receive a greater volume of air, allowing for more fuel to be injected and burned. This results in a significant increase in power output.

- Wastegate Control: As boost pressure increases, the wastegate is activated, allowing some exhaust gas to bypass the turbine. This regulates boost pressure and prevents over-boosting.

Real-World Use - Basic Troubleshooting Tips

Here are a few common issues and how to approach them:

- Loss of Power/Slow Acceleration: Could be caused by a boost leak (a leak in the intake system), a faulty wastegate, or a failing turbocharger. Check for loose hoses and clamps, and listen for hissing sounds. A boost gauge can help you determine if the turbocharger is producing the expected amount of boost.

- Excessive Smoke (Blue): Often indicates oil leaking into the turbocharger. This can be caused by worn turbocharger seals or a problem with the engine's PCV (Positive Crankcase Ventilation) system.

- Whining Noise from Turbocharger: Could indicate worn turbocharger bearings. This often precedes turbocharger failure.

- Check Engine Light (CEL): Many issues with the turbocharger system can trigger a CEL. Use an OBD-II scanner to read the diagnostic trouble codes (DTCs) and troubleshoot accordingly.

Safety – Highlight Risky Components

Working on a turbocharged engine involves several potential hazards:

- High Temperatures: The turbocharger and exhaust components get extremely hot. Allow the engine to cool completely before working on these parts. Wear appropriate protective gear, such as heat-resistant gloves.

- High Pressure: The intake system is under high pressure when the engine is running. Relieve pressure before disconnecting hoses or components.

- Rotating Parts: The turbocharger's turbine and compressor wheels spin at extremely high speeds. Never insert anything into the turbocharger while the engine is running.

- Oil System: The turbocharger relies on engine oil for lubrication. Ensure proper oil levels and quality to prevent turbocharger damage.

Important Safety Note: When working on the fuel system, ensure the engine is cool and disconnect the negative battery cable. Fuel is highly flammable and can be dangerous.

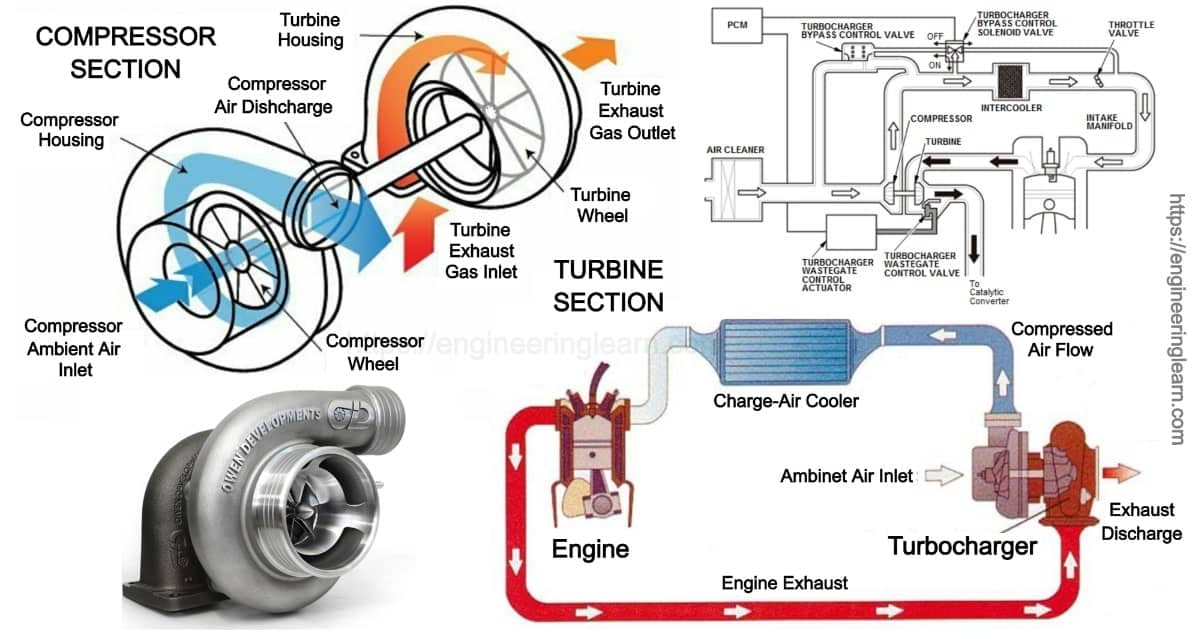

Diagram Explanation

While I can't visually provide a diagram here, imagine a schematic showing all the components we discussed – the exhaust manifold leading to the turbine housing, the turbine and compressor wheels connected by a shaft, the wastegate diverting exhaust, the compressed air flowing through the intercooler, and finally entering the intake manifold. Lines would indicate airflow and oil flow. Arrows would show direction. Different colors might highlight pressure zones or temperature differences.

The purpose of such a diagram, whether it's one in a repair manual or one you find online, is to visually represent the system for better understanding and troubleshooting. For repairs, it helps you identify components, trace lines (both air and fluid), and understand the flow of gases/fluids within the system. For learning, it reinforces the concepts we've discussed and helps you visualize the relationships between different parts.

Symbols you'll find will be pretty standard mechanical drawings symbols. Solid lines generally represent physical connections (pipes, hoses, shafts). Dotted lines might represent vacuum lines or signal lines (electrical connections). Arrows show the direction of flow of fluids or gases. Different fill colors may represent different fluids (oil, coolant, air) or different pressure levels.

Remember that working on turbo systems, especially modifying them, can significantly impact your engine's performance and reliability. Always consult with a qualified mechanic or tuner before making any significant changes.

We have a detailed diagram of a typical turbo engine available for download. It includes detailed labeling of all components and shows the flow of air, exhaust, and oil throughout the system. This can be a valuable resource for further study and hands-on work.