What Motor Is In A Gtr

Let's dive into the heart of the Nissan GT-R: its engine. Understanding the intricacies of this powerplant is crucial whether you're planning on tackling basic maintenance, considering performance upgrades, or simply want to appreciate the engineering marvel that powers this iconic sports car. This guide will walk you through the key aspects of the GT-R's engine, the VR38DETT, covering its specs, operation, and some basic troubleshooting tips.

Why Understanding the VR38DETT Matters

Having a solid understanding of your GT-R's engine offers numerous benefits:

Informed Maintenance: Knowing the location and function of key components allows you to perform preventative maintenance more effectively and diagnose potential problems early on.

Targeted Upgrades: When considering modifications, understanding the engine's limitations and the impact of upgrades is essential for achieving desired performance gains without compromising reliability.

Effective Troubleshooting: When issues arise, a deeper understanding of the engine's operation can significantly reduce diagnostic time and prevent misdiagnosis.

Key Specs and Main Parts of the VR38DETT

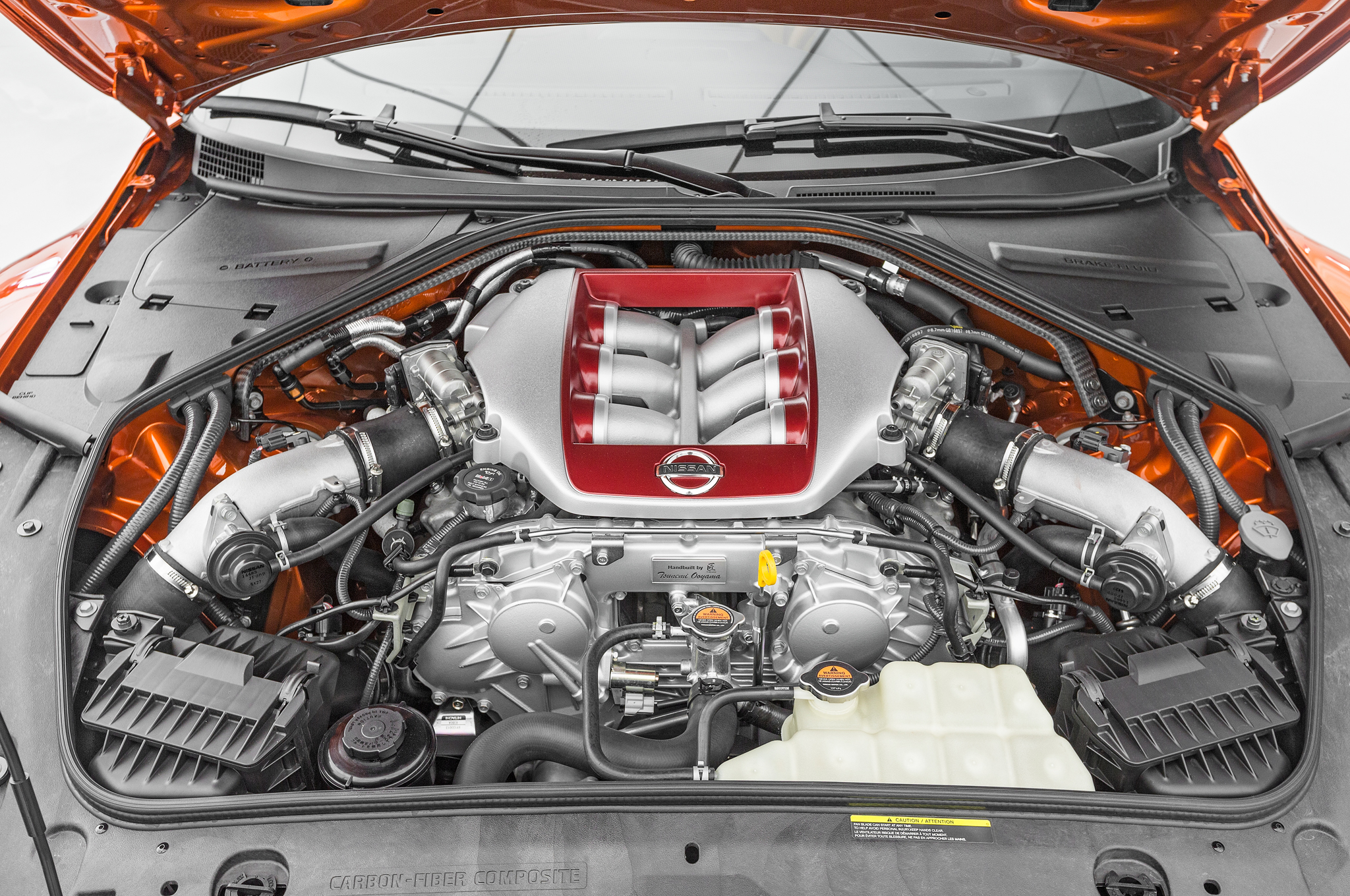

The VR38DETT is a 3.8-liter (3799 cc) 24-valve DOHC V6 engine with twin turbochargers. Here’s a breakdown of some key specifications:

- Configuration: 60° V6

- Displacement: 3.8 liters (3799 cc)

- Bore x Stroke: 95.5 mm x 88.4 mm

- Compression Ratio: 9.0:1 (varies slightly with model year)

- Valve Train: DOHC, 4 valves per cylinder, continuously variable valve timing control system (CVTCS) on both intake and exhaust cams

- Fuel System: Multi-point fuel injection

- Turbochargers: Two IHI turbochargers (model varies with model year)

- Horsepower: Ranges from 480 hp (358 kW) to 600 hp (447 kW) or more, depending on the model year and tune.

- Torque: Ranges from 430 lb-ft (583 Nm) to 481 lb-ft (652 Nm) or more, depending on model year and tune.

The main parts include:

- Cylinder Block: Aluminum alloy construction with cast iron cylinder liners.

- Cylinder Heads: Aluminum alloy, featuring optimized combustion chamber design.

- Crankshaft: Forged steel, designed for high strength and durability.

- Connecting Rods: Forged steel, connecting the pistons to the crankshaft.

- Pistons: Lightweight aluminum alloy, designed for efficient combustion.

- Turbochargers: IHI turbochargers, one for each cylinder bank, providing forced induction.

- Intercoolers: Air-to-air intercoolers, cooling the compressed air from the turbochargers.

- Intake Manifold: Optimized for airflow distribution to the cylinders.

- Exhaust Manifold: Directs exhaust gases to the turbochargers.

- Fuel Injectors: High-flow injectors for precise fuel delivery.

- Ignition System: Individual coil-on-plug ignition system for each cylinder.

- Engine Control Unit (ECU): Manages all aspects of engine operation.

How the VR38DETT Works

The VR38DETT operates on the four-stroke combustion cycle:

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel into the cylinder. The CVTCS system optimizes valve timing for maximum cylinder filling.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion: The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases that pushes the piston down.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder and into the exhaust manifold, then through the turbocharger turbines and out of the exhaust system. The CVTCS system optimizes valve timing for efficient exhaust scavenging.

The twin turbochargers play a crucial role. Exhaust gases spin the turbines, which in turn drive compressors that force more air into the cylinders. This increased air intake allows for more fuel to be burned, resulting in significantly increased power output. The intercoolers cool the compressed air from the turbos, further increasing air density and power.

Real-World Use: Basic Troubleshooting

Here are some common issues and potential causes:

- Loss of Power: Possible causes include faulty spark plugs, vacuum leaks, boost leaks, failing turbochargers, or issues with the fuel system.

- Engine Knocking: Could be caused by low-octane fuel, detonation, or pre-ignition. Requires immediate attention to prevent engine damage.

- Check Engine Light: Requires diagnostic scanning to identify the error code and pinpoint the problem. Common causes include sensor failures, emissions system issues, or engine misfires.

- Excessive Oil Consumption: Could indicate worn piston rings, valve stem seals, or turbocharger oil seals.

Always start with basic checks such as fluid levels, visual inspection for leaks, and a diagnostic scan before attempting more complex repairs.

Safety Considerations

Working on the VR38DETT involves inherent risks:

- High Voltage: The ignition system operates at high voltage. Always disconnect the battery before working on the ignition system.

- Hot Surfaces: The exhaust system and turbochargers become extremely hot during operation. Allow them to cool completely before handling.

- Fuel System: The fuel system is under pressure. Relieve pressure before disconnecting fuel lines to prevent fuel spills and potential fire hazards.

- Moving Parts: Be extremely cautious when the engine is running to avoid contact with moving parts like the belts, pulleys, and fans.

Always wear appropriate safety gear, including eye protection and gloves.

In Conclusion

The VR38DETT is a sophisticated engine that demands respect and understanding. This overview provides a foundation for further learning and will hopefully aid you in maintaining and appreciating the engineering prowess of the Nissan GT-R.