What Motor Is In The 370z

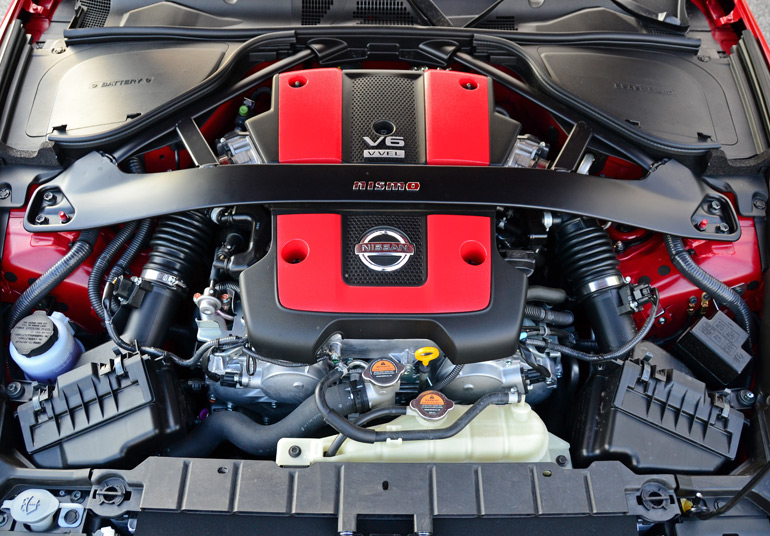

Alright, let's dive into the heart of the Nissan 370Z: the engine. Specifically, we're talking about the VQ37VHR, a powerplant that's become synonymous with Nissan's performance heritage. This article is your deep dive into understanding this engine, its workings, and how to keep it running smoothly. Whether you're tackling a repair, planning a modification, or just want to understand your Z better, knowing your engine is crucial.

Purpose and Importance

Understanding the VQ37VHR is paramount for a variety of reasons. For repairs, knowing the location and function of each component saves time and prevents costly mistakes. For modifications, grasping the engine's architecture allows you to make informed decisions about upgrades that truly enhance performance. And even for basic maintenance, a deeper understanding equips you to diagnose potential issues early, preventing major breakdowns. Let’s face it, having an intimate knowledge of your engine not only saves you money but also gives you bragging rights at the next car meet!

Key Specs and Main Parts of the VQ37VHR

The VQ37VHR is a 3.7-liter (3696cc) naturally aspirated V6 engine, known for its high-revving nature and responsive power delivery. Here's a rundown of its key specifications:

- Configuration: 60-degree V6

- Displacement: 3.7 liters (3696 cc)

- Bore x Stroke: 95.5 mm x 86 mm

- Compression Ratio: 11.0:1

- Valve Train: DOHC, 24 valves (4 valves per cylinder)

- Fuel System: Multi-point fuel injection

- Horsepower: Typically ranges from 332 hp to 350 hp, depending on the model year and trim

- Torque: Around 270 lb-ft

Now, let's break down the main components:

- Cylinder Block: The foundation of the engine, housing the cylinders, pistons, and crankshaft. It's typically made of aluminum alloy for weight reduction.

- Cylinder Heads: Sit atop the cylinder block and house the valves, camshafts, and spark plugs. The VQ37VHR features dual overhead camshafts (DOHC) for precise valve control.

- Pistons: Move up and down within the cylinders, driven by the combustion process. Connected to the crankshaft via connecting rods.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, which is then transmitted to the transmission.

- Connecting Rods: Connect the pistons to the crankshaft.

- Valves: Control the flow of air and fuel into the cylinders and exhaust gases out. Intake valves let the air/fuel mixture in, while exhaust valves let exhaust gases out.

- Camshafts: Control the opening and closing of the valves. The VQ37VHR uses Variable Valve Event and Lift (VVEL) technology on the intake side.

- VVEL (Variable Valve Event and Lift): This is a crucial technology. Instead of traditional throttle bodies, VVEL adjusts the *lift* and *duration* of the intake valves. This provides precise control over airflow and improves throttle response and fuel efficiency.

- Fuel Injectors: Spray fuel into the intake ports or directly into the cylinders (depending on the specific design).

- Intake Manifold: Distributes air to the cylinders.

- Exhaust Manifold: Collects exhaust gases from the cylinders.

- Catalytic Converters: Reduce harmful emissions in the exhaust gases.

- ECU (Engine Control Unit): The brain of the engine, controlling fuel injection, ignition timing, and other parameters based on sensor inputs.

How It Works: The Combustion Cycle

The VQ37VHR operates on the four-stroke combustion cycle:

- Intake: The piston moves down, creating a vacuum that draws air and fuel (or just air in direct injection engines) into the cylinder. The intake valve is open.

- Compression: The piston moves up, compressing the air-fuel mixture. Both intake and exhaust valves are closed.

- Combustion (Power): The spark plug ignites the compressed mixture, creating a powerful explosion that forces the piston down. This is where the engine generates its power. Both valves are closed.

- Exhaust: The piston moves up, pushing the exhaust gases out of the cylinder through the open exhaust valve.

This cycle repeats continuously in each cylinder, generating the power that propels the 370Z.

Real-World Use: Basic Troubleshooting Tips

Let's look at some common issues you might encounter and how to approach them:

- Rough Idle: Could be caused by a vacuum leak, faulty spark plugs, dirty fuel injectors, or a malfunctioning mass airflow (MAF) sensor. Start by visually inspecting vacuum lines for cracks and checking the spark plugs.

- Loss of Power: Could stem from a clogged air filter, a failing fuel pump, or issues with the VVEL system. Check the air filter first.

- Check Engine Light (CEL): The CEL is your engine's way of telling you something is wrong. Use an OBD-II scanner to retrieve the trouble codes. These codes provide valuable clues about the nature of the problem. Common codes on the VQ37VHR might relate to camshaft position sensors, oxygen sensors, or VVEL actuators.

- Oil Leaks: Common leak points include the valve covers, oil pan, and front crankshaft seal. Regularly inspect these areas for signs of leaks.

- Coolant Leaks: Check the radiator hoses, water pump, and thermostat housing for leaks. Low coolant levels can lead to overheating, which can severely damage the engine.

Important: Always consult your service manual for specific diagnostic procedures and torque specifications.

Safety Considerations

Working on any engine involves risks. Here are some key safety points to remember:

- Electrical System: The electrical system carries high voltage. Disconnect the negative battery terminal before working on any electrical components. Even after disconnection, capacitors can hold a charge, so be cautious.

- Fuel System: Fuel is highly flammable. Work in a well-ventilated area and avoid open flames. Relieve fuel pressure before disconnecting fuel lines.

- Exhaust System: The exhaust system gets extremely hot. Allow it to cool completely before working on it.

- Moving Parts: Be extremely careful when working around moving parts, such as the crankshaft and camshafts. Ensure the engine is off and properly supported before attempting any work.

- VVEL System: The VVEL actuators are precision components. Handle them with care and avoid applying excessive force. Incorrect handling can damage them and affect engine performance.

- High Pressure Fluids: The fuel injection system operates at high pressure. Always relieve the pressure before disconnecting any fuel lines or components.

Always wear safety glasses and gloves when working on your engine.

Understanding VVEL in Detail

The VVEL system is a standout feature of the VQ37VHR. Unlike traditional throttle bodies that restrict airflow, VVEL uses eccentric cams and rocker arms to adjust the lift and duration of the intake valves independently. This offers several advantages:

- Improved Throttle Response: By directly controlling the valve lift, VVEL eliminates the lag associated with conventional throttle systems.

- Increased Power and Torque: VVEL optimizes airflow throughout the RPM range, resulting in higher power and torque output.

- Enhanced Fuel Efficiency: By precisely controlling the amount of air entering the cylinders, VVEL improves fuel economy.

The VVEL system is controlled by the ECU, which monitors various engine parameters and adjusts the valve lift accordingly. This complex system requires specialized diagnostic tools and knowledge for proper maintenance and repair. Malfunctions in the VVEL system can cause a variety of issues, including reduced power, poor fuel economy, and a check engine light.

Final Thoughts

The VQ37VHR is a sophisticated and powerful engine. Understanding its components and how they work together is essential for maintaining and modifying your 370Z. Remember to always prioritize safety and consult your service manual for specific procedures and specifications. With the knowledge you've gained here, you're well-equipped to tackle a wide range of maintenance and repair tasks.