What Order Do Dimensions Go In

Alright folks, let's dive into something fundamental for anyone who wants to understand how cars are designed and maintained: understanding the order in which dimensions are specified on technical diagrams. Think of this like the grammar of engineering drawings. You might instinctively know which way to tighten a bolt, but understanding torque specifications allows you to do it precisely and safely. Similarly, knowing the correct order of dimensions allows you to correctly interpret engineering diagrams, ensuring you don't make costly mistakes when fabricating, repairing, or modifying your vehicle.

Purpose – Why Mastering Dimension Order Matters

Why should you care about dimension order? Several reasons, mainly:

- Accurate Repairs: When replacing parts, understanding the dimensions ensures you order the correct size, avoiding fitment issues. If you're working with suspension components, chassis modifications, or even interior trim, knowing the exact dimensions is crucial.

- Successful Modifications: Modders, this is especially for you. Before you cut, weld, or drill anything, you need to be absolutely certain about the dimensions you're working with. Misinterpreting a drawing can lead to disastrous results and wasted time and money.

- Understanding Schematics: Whether it's a wiring diagram or a blueprint for a custom part, understanding how dimensions are conveyed is essential for interpreting the information.

- Troubleshooting: Dimensioned drawings are invaluable for diagnosing problems. Comparing the dimensions of worn parts to the original specifications can quickly identify wear and tear, deformation, or other issues.

- Reverse Engineering: Want to replicate a part? A clear understanding of dimension order is essential for accurately measuring and replicating existing components.

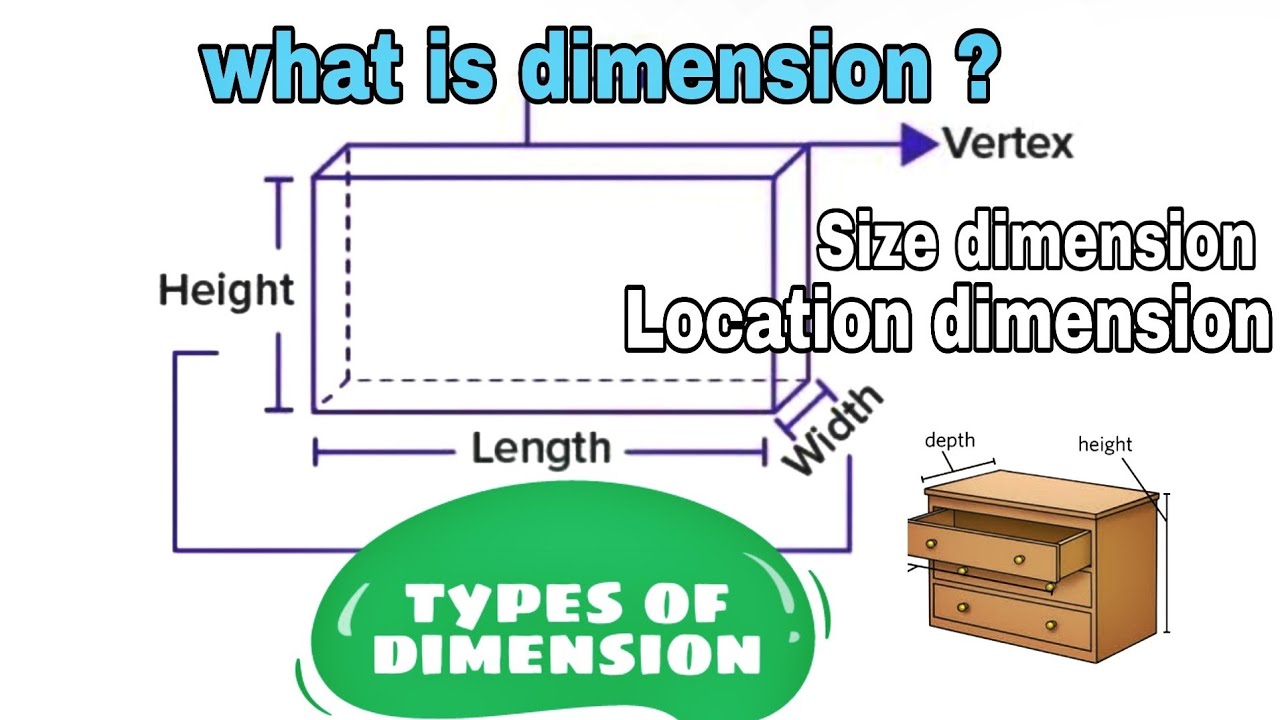

Key Specs and Main Parts of a Dimensioned Drawing

Before we get to the order, let's define some key terms and parts you'll find on a typical engineering or technical drawing:

- Object Lines: Thick, solid lines that represent the visible edges of the part.

- Hidden Lines: Dashed lines that represent edges and features that are hidden from the viewer.

- Center Lines: Lines used to indicate the center of circles, arcs, and symmetrical features. They are thin, with alternating long and short dashes.

- Dimension Lines: Thin lines that indicate the length of a dimension, terminated by arrowheads.

- Extension Lines: Thin lines that extend from the object to the dimension line, indicating the points between which the dimension is measured.

- Leaders: Lines used to connect a note or dimension to a specific feature on the drawing, usually terminating in an arrowhead or a dot.

- Dimensions: The numerical value representing the size or distance of a feature, placed near the dimension line. These are often in millimeters (mm) or inches (in), depending on the drawing standard.

- Tolerances: The permissible variation in a dimension. These indicate the acceptable range of deviation from the nominal size. A common notation is "+/-" followed by a value.

- Datum: A reference point, line, or plane from which dimensions are measured. This establishes a baseline for accuracy.

- Views: Different perspectives of the object (e.g., front, top, side) that provide a complete representation of its shape and dimensions.

Symbols – Deciphering the Lines, Colors, and Icons

Engineering drawings aren't just lines and numbers; they're a language of symbols. Here are some common ones you might encounter:

- Arrowheads: Used to terminate dimension lines, indicating the points between which the dimension is measured. Typically, they are closed and filled.

- Circles with Crosshairs: Indicate the center of a hole or circular feature.

- Surface Finish Symbols: Indicate the required surface texture of a part, vital for components needing specific friction properties or sealing capabilities.

- Welding Symbols: Used on fabrication drawings to specify the type, size, and location of welds.

- Geometric Dimensioning and Tolerancing (GD&T) Symbols: A complex system of symbols used to define the allowable variation in the form, orientation, and location of features. This is an advanced topic, but crucial for precision components. Examples include symbols for flatness, roundness, position, and parallelism.

- Color Coding: While not universally standardized, some drawings use color to differentiate components or highlight critical dimensions. Always refer to the drawing's legend for clarification.

Line Weights and Styles: Pay close attention to line thickness. Object lines are thick, while dimension and extension lines are thin. Hidden lines are dashed. The consistency of these line weights is vital for readability.

How It Works – The Hierarchy of Dimensions

Now, the heart of the matter: dimension order. There isn't one universal "order" in the sense of always listing length, width, height, *always*. Rather, there is a *logical* hierarchy that prioritizes clarity and minimizes ambiguity. Think of it this way: larger, more defining dimensions are generally placed further from the object, while smaller, more detailed dimensions are placed closer. This is a fundamental principle.

Here's a breakdown of key considerations:

- Overall Dimensions: The largest dimensions that define the overall size of the part are usually placed furthest away from the object. These provide a quick understanding of the part's envelope.

- Major Features: Dimensions relating to significant features (e.g., the diameter of a large hole, the length of a keyway) are placed next, working inwards.

- Detailed Dimensions: Dimensions specifying the size and location of smaller features (e.g., the diameter of a small hole, the chamfer on an edge) are placed closest to the object.

- Chain Dimensioning vs. Datum Dimensioning:

- Chain Dimensioning: Dimensions are placed end-to-end, creating a chain. While seemingly simple, this method can accumulate tolerances, leading to significant errors in overall size.

- Datum Dimensioning: All dimensions are measured from a common reference point (datum). This minimizes tolerance accumulation and ensures greater accuracy, especially important in complex assemblies. Datum dimensioning is generally preferred.

- Placement: Dimensions should be placed outside the object whenever possible to avoid cluttering the drawing. Dimensions should be clear and unambiguous, and avoid crossing dimension or extension lines.

- Standard Practices: Familiarize yourself with drafting standards like ASME Y14.5 (Geometric Dimensioning and Tolerancing) or ISO standards. These standards provide guidelines for dimensioning practices and symbol usage, promoting consistency and clarity.

Example: Imagine a rectangular metal bracket. The overall length and width of the bracket would be dimensioned first (furthest from the bracket). Then, the position and size of a mounting hole drilled through the bracket would be dimensioned closer to the bracket itself. Finally, any chamfers or fillets on the edges would be dimensioned closest of all.

Real-World Use – Basic Troubleshooting Tips

So, you're looking at a drawing and something doesn't seem right. Here are some troubleshooting tips:

- Check Units: Are the dimensions in millimeters or inches? A common mistake is misinterpreting the units, leading to parts that are dramatically oversized or undersized.

- Verify Datums: Identify the datum points or surfaces. Are the dimensions referenced correctly? An incorrect datum can throw off all subsequent measurements.

- Calculate Tolerance Stack-Up: If you're using chain dimensioning, calculate the potential accumulation of tolerances. This can help you determine if a part is within acceptable limits.

- Compare to Known References: If possible, compare the drawing to a known good part or assembly. This can help you identify discrepancies in the dimensions.

- Look for Missing Dimensions: Is there a dimension missing? A drawing isn't useful if critical dimensions are absent. You may need to contact the manufacturer or designer for clarification.

- Use Appropriate Measuring Tools: Use calibrated calipers, micrometers, and other precision measuring tools to accurately verify dimensions.

Safety – Highlighting Risky Components

Working with technical diagrams and dimensioned parts can involve potentially hazardous components. Here are a few areas to be particularly cautious of:

- High-Pressure Systems: Dimensions related to hydraulic or pneumatic systems are critical. Incorrect fittings or dimensions can lead to leaks or explosions. Always use the correct tools and follow safety procedures when working with these systems.

- Electrical Components: Dimensions related to wiring harnesses, connectors, and electrical enclosures are essential for preventing shorts or electrical hazards. Pay close attention to insulation requirements and wire gauge specifications.

- Suspension Components: Dimensions related to suspension components (e.g., springs, shocks, control arms) are critical for vehicle handling and stability. Incorrect dimensions can lead to dangerous driving conditions. Always consult a qualified professional before modifying suspension components.

- Brake Components: Dimensions of brake rotors, calipers, and lines are vitally important for safety. Improper repair or modification can result in brake failure. Leave brake work to the professionals unless you have extensive experience.

Remember, when in doubt, consult with a qualified mechanic or engineer. Precision and accuracy are paramount when working with automotive components.

We have a sample dimensioned drawing file available for you to download and practice with. Contact us to get the file and further enhance your understanding of this topic.