What Size Is Spark Plug Socket

Alright, let's talk spark plug sockets. Getting the right one is crucial for spark plug replacement and maintenance. Using the wrong size can lead to damaged plugs, stripped threads, and a whole lot of frustration. This article will break down everything you need to know to choose the correct spark plug socket, covering the key specs, how they work, and even some troubleshooting tips.

Why Understanding Spark Plug Socket Sizes Matters

Why bother diving into the specifics of spark plug sockets? Because accurate repairs and maintenance depend on it. Specifically, understanding the proper socket size helps with:

- Spark Plug Replacement: The primary reason. Changing your spark plugs at the recommended intervals keeps your engine running smoothly and efficiently.

- Diagnosing Engine Problems: Examining the condition of your spark plugs can reveal clues about your engine's health, such as rich or lean fuel mixtures, oil fouling, or coolant leaks. Removing them requires the correct socket.

- Preventing Damage: Using the wrong size can easily damage the delicate ceramic insulator of the spark plug or strip the threads in the cylinder head, leading to expensive repairs.

- Learning Engine Mechanics: Understanding the tools involved in basic engine maintenance is a step towards becoming a more confident and capable DIY mechanic.

Key Specs and Main Parts

A spark plug socket isn't just any socket. It has specific features designed for the unique shape and fragility of spark plugs. Let's break down the key components:

- Socket Size (Drive Size): This refers to the size of the square opening that connects to your ratchet or torque wrench. Common sizes are 3/8" and 1/2". This has nothing to do with the size of the spark plug itself.

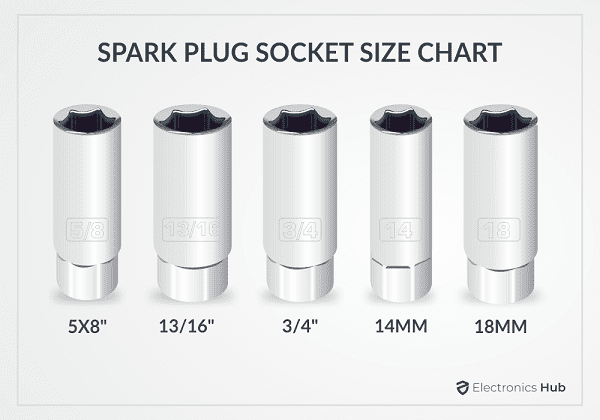

- Socket Size (Spark Plug Hex Size): This is the key measurement. It refers to the size of the hexagonal (six-sided) opening that fits around the spark plug's nut. This is the *actual* size that matters for fitting the spark plug. This is typically measured in millimeters, with the most common sizes being 16mm (5/8") and 14mm (9/16"). Note the conversion is *approximate*.

- Depth: Spark plugs are recessed within the cylinder head. Spark plug sockets are typically longer than standard sockets to reach down into these recesses.

- Rubber Insert (or Magnetic Insert): A critical feature. This insert is located inside the socket and grips the spark plug securely, preventing it from falling out when removing or installing it. The rubber insert is a rubber sleeve that fits snugly around the ceramic insulator. A magnetic insert uses a magnet to hold the plug.

- Swivel Joint (Optional): Some spark plug sockets come with a swivel joint (universal joint). This allows you to access spark plugs in tight or awkwardly angled locations.

Think of it this way: a standard socket is like a regular glove. A spark plug socket is like a specialized glove designed to protect and handle a delicate object with a specific shape.

Understanding Spark Plug Hex Sizes: Metric vs. Imperial

Most modern vehicles use metric-sized spark plugs. However, some older vehicles, particularly those from North America, may use imperial (inch-based) sizes. It's vital to know which one your vehicle uses. Confusing the two can lead to damage.

- 16mm (5/8"): A very common size, often found in older vehicles and some newer ones.

- 14mm (9/16"): Increasingly common in newer, especially European, vehicles. Pay close attention, as a 14mm socket is smaller and will damage a 16mm spark plug.

It's always best to consult your vehicle's owner's manual or a reliable online parts database to determine the correct spark plug size for your specific make and model.

How Spark Plug Sockets Work

The mechanics of a spark plug socket are straightforward but effective. Here's the breakdown:

- Selection: Choose the correct spark plug socket size (hex size) for your spark plugs. This is determined by the spark plug's nut size, not the drive size of your ratchet.

- Attachment: Attach the socket to your ratchet or torque wrench using the appropriate drive size. Ensure it's securely connected.

- Insertion: Carefully insert the socket into the spark plug well, guiding it over the spark plug. The rubber or magnetic insert should grip the spark plug.

- Loosening/Tightening: Apply gentle, even pressure to loosen or tighten the spark plug. If it's stuck, avoid forcing it. Use a penetrating oil and try again later.

- Removal/Installation: Once loose, carefully remove the spark plug, ensuring the rubber or magnetic insert holds it securely. When installing, thread the spark plug in by hand first to avoid cross-threading.

The rubber or magnetic insert is critical. Without it, the spark plug can easily fall out, potentially damaging the ceramic insulator or even dropping into the engine compartment. The socket's depth ensures it reaches the spark plug, which is often located deep within the cylinder head.

Real-World Use and Basic Troubleshooting

Let's look at some common scenarios and troubleshooting tips:

- Socket Doesn't Fit: This is the most common problem. Double-check the spark plug hex size. If it's too small, you'll damage the plug. If it's too large, the socket will slip.

- Spark Plug Stuck: If the spark plug is seized, don't force it. Apply a penetrating oil (like PB Blaster) around the base of the plug and let it soak for several hours or even overnight. Gently try again. Repeat if necessary.

- Rubber Insert Torn or Missing: Replace the socket immediately. A damaged insert won't grip the spark plug properly.

- Difficulty Reaching the Plug: Use a spark plug socket with a swivel joint. This will allow you to access plugs in tight or awkwardly angled locations. A spark plug extension may also be required.

- Torque Wrench Settings: Always torque spark plugs to the manufacturer's recommended torque specifications. Overtightening can damage the cylinder head; undertightening can cause leaks.

Important Tip: Always use anti-seize compound on the threads of new spark plugs (unless the spark plugs come pre-coated with anti-seize from the factory, which some do). This will prevent them from seizing in the future.

Safety Considerations

Working with spark plugs involves some potential hazards:

- High Voltage: While the spark plugs themselves don't store electricity, the ignition system delivers high voltage to them. Ensure the ignition system is completely off before working on spark plugs. Disconnect the negative battery terminal for added safety.

- Hot Engine: Never work on spark plugs when the engine is hot. Allow it to cool completely to avoid burns.

- Stripped Threads: This is a major risk. Cross-threading or overtightening spark plugs can severely damage the cylinder head, requiring expensive repairs. Always thread spark plugs in by hand first and use a torque wrench to tighten them to the correct specification.

- Falling Debris: Keep the spark plug wells clean. Debris falling into the cylinder can cause engine damage. Use compressed air to blow out any dirt or debris before removing the spark plugs.

Always wear safety glasses when working on your car. Even small particles of dirt can cause serious eye injury.

By understanding the purpose and the parts of a spark plug socket, you are in a much better position to diagnose and maintain your engine. Take your time, and you will be fine!