What Thickness Are New Brake Pads

Alright, let's talk brake pad thickness. As someone who's probably spent more time under a car than in one lately, I know how critical brakes are. You're here because you're either planning a brake job, trying to diagnose a problem, or just want to deepen your understanding. Either way, knowing the ins and outs of brake pad thickness is crucial for both safety and preventing costly damage to your rotors.

Purpose of Understanding Brake Pad Thickness

Understanding brake pad thickness isn't just about knowing when to replace them; it's about preventative maintenance and recognizing potential issues early. Think of it this way: routinely checking pad thickness lets you spot uneven wear, which could point to a sticking caliper, a collapsed brake hose, or other problems in the braking system. Ignoring these issues can lead to scored rotors (expensive!), longer stopping distances (dangerous!), and potentially a complete brake failure (catastrophic!). Knowing the spec also helps when choosing new pads, ensuring you're getting the correct size and friction material for your vehicle and driving style.

Key Specs and Main Parts

Let's break down the key specs involved when discussing brake pad thickness. We're talking about more than just the total pad thickness.

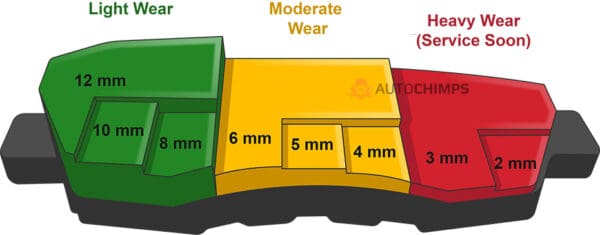

- New Pad Thickness: This is the starting thickness of a brand-new brake pad, including the friction material (the part that actually contacts the rotor) and the backing plate (the metal part that supports the friction material). This typically ranges from 8mm to 12mm (0.32" to 0.47"), but can vary significantly depending on the vehicle and pad type.

- Minimum Pad Thickness: This is the crucial number. It's the *thinnest* the friction material can be before the pads *must* be replaced. Going below this thickness severely compromises braking performance and risks damage to the rotors. The minimum thickness is generally around 2mm to 3mm (0.08" to 0.12"). Many pads will have a built in wear indicator that will begin squealing when you reach this point.

- Backing Plate Thickness: While you're not replacing the backing plate, understanding its role is important. It's the metal structure that supports the friction material and is generally around 4mm to 6mm thick. The backing plate is not included in the minimum pad thickness measurement.

- Friction Material: The actual material that is pressed onto the rotor to stop the car. This is the part that wears down and needs to be monitored. Different materials offer varying performance characteristics.

Main Parts in Context:

- Brake Pad: The entire assembly, including the friction material and the backing plate.

- Rotor (or Disc): The rotating metal disc that the brake pads clamp onto.

- Caliper: The assembly that houses the brake pads and pistons, providing the force to press the pads against the rotor.

- Piston: The component within the caliper that pushes the brake pad against the rotor.

How It Works

When you press the brake pedal, hydraulic pressure is applied to the calipers. This pressure forces the pistons inside the calipers to extend, pushing the brake pads against the rotor. The friction between the pads and the rotor slows the rotor's rotation, which in turn slows the wheels and the vehicle. Over time, the friction material on the brake pads wears away due to this constant contact. That's why regular inspection of brake pad thickness is essential.

The Importance of Even Wear: Ideally, both brake pads on a single wheel should wear at roughly the same rate. Uneven wear can indicate a problem with the caliper, such as a sticking piston, or a problem with the brake hoses. If one pad is significantly thinner than the other, it's a sign to investigate further.

Real-World Use – Basic Troubleshooting Tips

Okay, so you're ready to check your brake pads. Here's how to do it and what to look for:

- Visual Inspection: Without removing the wheel, you can often get a decent idea of pad thickness by looking through the spokes. Shine a flashlight into the caliper and look at the edge of the pad. Try to estimate the thickness of the remaining friction material.

- Wheel Removal: For a more accurate measurement, remove the wheel. This gives you a clear view of the entire brake pad.

- Measurement: Use a brake pad thickness gauge (available at most auto parts stores) to accurately measure the thickness of the friction material. These gauges often have markings for "safe" and "replace" zones. If you don't have a gauge, you can use a ruler or caliper, but be careful not to damage the friction material.

- Compare to Specs: Refer to your vehicle's service manual or the manufacturer's specifications for the *minimum* allowable brake pad thickness.

- Look for Uneven Wear: As mentioned earlier, check for significant differences in thickness between the inner and outer pads on the same wheel, and between the pads on different wheels.

Troubleshooting Scenarios:

- Squealing Brakes: Often indicates worn brake pads with a built-in wear indicator. Replace the pads.

- Grinding Noises: A more serious issue. Could mean the friction material is completely gone, and the backing plate is rubbing against the rotor. Stop driving the vehicle immediately! This requires immediate attention to avoid major rotor damage.

- Pulsating Brake Pedal: Could indicate warped rotors. Requires rotor resurfacing or replacement.

- Pulling to One Side During Braking: Can indicate a sticking caliper or a problem with the brake hoses.

Safety – Highlight Risky Components

Brake systems are safety-critical, so it's essential to take precautions:

- Brake Fluid: Brake fluid is corrosive and can damage painted surfaces. Wear gloves and eye protection when working with it. Also, brake fluid absorbs moisture from the air, which can reduce its effectiveness. Always use fresh, unopened brake fluid.

- Brake Dust: Brake dust can contain asbestos (especially in older vehicles). Wear a mask when working around brakes to avoid inhaling brake dust. Clean brake components with a brake cleaner specifically designed for the purpose.

- Hot Components: Brakes can get extremely hot during and after use. Allow them to cool down completely before working on them to avoid burns.

- Jacking and Support: Always use jack stands to support the vehicle when working underneath it. Never rely solely on the jack.

- Proper Torque: Ensure all bolts and nuts are tightened to the correct torque specifications using a torque wrench. This is especially important for wheel lug nuts and caliper mounting bolts.

Never underestimate the importance of properly functioning brakes. If you're not comfortable performing brake work yourself, take your vehicle to a qualified mechanic.

I hope this detailed explanation helps you understand brake pad thickness and its importance. Remember, regular inspections and timely replacements are key to safe and reliable braking performance. Safe driving!