What Type Engine Do I Have

So, you want to figure out what type of engine you have under the hood? Smart move. Knowing your engine type is crucial for everything from ordering the right parts and performing accurate diagnostics to understanding potential performance modifications. This article will equip you with the knowledge to identify your engine and grasp its fundamental workings.

Why Understanding Your Engine Type Matters

Think of it this way: your engine is the heart of your vehicle. Knowing its specific architecture is fundamental to just about every aspect of automotive ownership and repair. Here's why:

- Parts Compatibility: Ordering the wrong spark plugs, air filter, or timing belt? That can happen if you don't know your engine type. Correct part identification saves you time, money, and frustration.

- Repair Accuracy: Diagnosing a misfire on an inline-4 is different from diagnosing one on a V6. Knowing the engine configuration helps you pinpoint the problem faster and more accurately.

- Performance Upgrades: Different engine types respond differently to modifications. Supercharging a naturally aspirated engine is a totally different ballgame than tuning a turbocharged one. You need to understand your engine’s foundation before even considering modifications.

- Maintenance Schedules: Valve adjustment intervals, oil change frequencies, and other maintenance procedures vary based on engine type. Following the wrong schedule can lead to premature wear and tear.

Key Engine Types: Architecture and Specifications

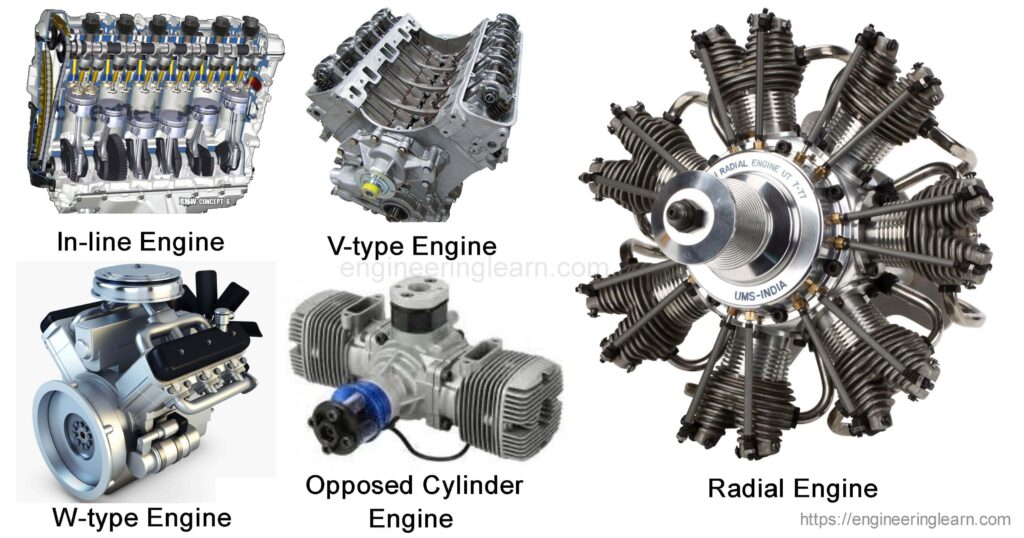

Engines are classified based on several factors, including cylinder arrangement, valve train configuration, fuel delivery method, and aspiration. Let's dive into some of the most common types:

Cylinder Arrangement

- Inline (Straight) Engines: Cylinders are arranged in a single row. Examples include inline-4 (I4) and inline-6 (I6) engines. These are generally simpler in design and offer good balance (especially the I6), but can be long, limiting engine bay packaging.

- V Engines: Cylinders are arranged in two banks, forming a "V" shape. Common examples include V6 and V8 engines. V engines are shorter than inline engines, allowing for better packaging, and can deliver more power due to having more cylinders.

- Flat (Boxer) Engines: Cylinders are arranged horizontally, on opposite sides of the crankshaft. Think Subaru and some Porsche models. Boxer engines offer excellent balance and a low center of gravity, which improves handling.

Valve Train Configuration

- Overhead Valve (OHV) or Pushrod Engines: The camshaft is located within the engine block, and pushrods actuate the valves in the cylinder head. OHV engines are typically more compact but have limitations in high-RPM performance.

- Overhead Camshaft (OHC) Engines: The camshaft is located in the cylinder head, directly above the valves. This allows for better valve control and higher RPM potential. OHC engines can be either single overhead camshaft (SOHC) or dual overhead camshaft (DOHC).

- Single Overhead Camshaft (SOHC): Uses one camshaft per cylinder bank to actuate both intake and exhaust valves.

- Dual Overhead Camshaft (DOHC): Uses two camshafts per cylinder bank – one for intake valves and one for exhaust valves. This provides even greater control over valve timing and allows for more aggressive valve profiles.

Fuel Delivery

- Carbureted Engines: Use a carburetor to mix air and fuel before it enters the cylinders. Becoming less common due to emissions regulations and advancements in fuel injection.

- Fuel Injected Engines: Inject fuel directly into the intake manifold (port fuel injection) or directly into the cylinders (direct injection). Fuel injection offers more precise fuel control, improved fuel economy, and lower emissions.

- Port Fuel Injection (PFI): Fuel is injected into the intake port, just before the intake valve.

- Direct Injection (DI): Fuel is injected directly into the combustion chamber. DI provides even greater control over fuel delivery and allows for higher compression ratios, resulting in improved power and efficiency.

Aspiration

- Naturally Aspirated (NA): Engines that rely solely on atmospheric pressure to fill the cylinders.

- Forced Induction: Engines that use a turbocharger or supercharger to force more air into the cylinders, resulting in increased power output.

- Turbocharged: Uses exhaust gas to spin a turbine, which in turn compresses intake air.

- Supercharged: Uses engine power (typically via a belt-driven system) to compress intake air.

How the Engine Works: The Four-Stroke Cycle

Most modern engines operate on the four-stroke cycle, which consists of four distinct phases:

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating an explosion that forces the piston down.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

This cycle repeats continuously, converting chemical energy (fuel) into mechanical energy (motion).

Real-World Use: Basic Troubleshooting

Knowing your engine type is essential for troubleshooting. Here are a few examples:

- Misfires: A misfire on a single cylinder in an inline-4 engine is easier to isolate than a misfire in a V6, where you need to determine which cylinder bank is affected first. Knowing the cylinder firing order is also crucial.

- Oil Leaks: Different engine types have different potential leak points. For example, V engines are more prone to valve cover gasket leaks on both cylinder banks.

- Overheating: Overheating can be caused by a variety of factors, but knowing your engine type helps you narrow down the possibilities. For example, a blown head gasket is more likely to cause overheating in a high-compression engine.

If you're experiencing engine problems, start by consulting your vehicle's repair manual and online resources specific to your engine type.

Safety Considerations

Working on engines can be dangerous. Always follow these safety precautions:

- Disconnect the Battery: Disconnect the negative battery terminal before working on any electrical components.

- Wear Safety Glasses: Protect your eyes from flying debris.

- Use Proper Tools: Use the right tools for the job to avoid damaging components.

- Be Aware of Hot Surfaces: Engines can get extremely hot. Allow the engine to cool down completely before working on it. Be especially careful around the exhaust manifold and catalytic converter, which can remain hot for a long time.

- Fuel is Flammable: Work in a well-ventilated area when dealing with fuel. Avoid sparks and open flames.

- High Voltage Systems: Direct Injection systems often have very high voltage. Ensure you know how to safely discharge these systems before working on them.

Working on engines requires knowledge and caution. If you're not comfortable performing a particular task, it's always best to consult a qualified mechanic.

Moving Forward

Identifying your engine type is a fundamental step in understanding your vehicle. Armed with this knowledge, you'll be better equipped to perform maintenance, diagnose problems, and even explore performance upgrades.

This article has provided a general overview. For a specific breakdown relevant to the engine of *your* car, consult your owner's manual, the VIN (Vehicle Identification Number) plate usually found on the driver's side door jamb or dashboard, and consult online databases or your local dealer.

We have access to detailed engine diagrams and specifications that may be useful for your specific make and model. Please reach out through our contact form if you'd like to inquire about receiving a downloadable file tailored to your needs.