What Was The Titan Sub Made Of

Alright, let's dive into the materials used in the construction of the Titan submersible. This isn't your average weekend oil change, but understanding the material choices is crucial if you're interested in deep-sea engineering, underwater vehicles, or just want to understand more about what happened to the Titan. Think of this as taking apart an engine – knowing what the components are made of helps you understand how they're supposed to work and why they might fail.

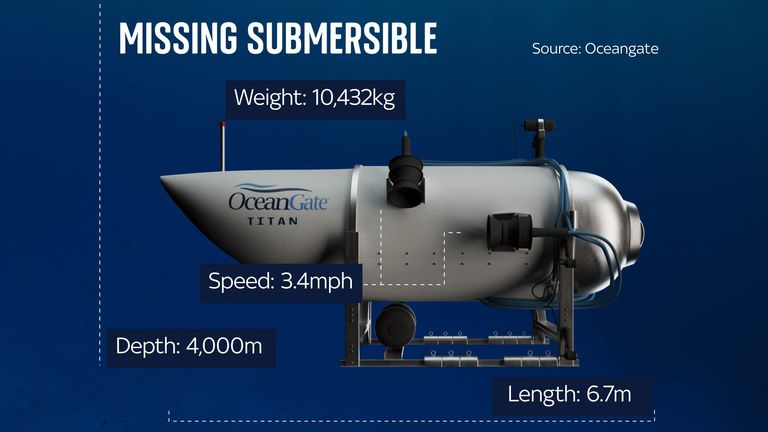

Key Specs and Main Parts

The Titan's hull was the subject of much debate and, ultimately, scrutiny. Its core comprised two primary materials: Carbon Fiber and Titanium. Here's a breakdown:

Carbon Fiber Composite Hull

This was the most innovative, and controversial, aspect of the Titan's design. Carbon fiber composites are prized for their high strength-to-weight ratio. They are created by bonding layers of carbon fibers together with a resin matrix. Think of it like layering sheets of fiberglass, but with incredibly strong carbon fibers. The orientation of these fibers is meticulously planned to provide maximum strength in specific directions.

- Layup Technique: Crucially, the Titan’s carbon fiber was filament wound, meaning the carbon fiber strands were wound around a mandrel (a mold) in a specific pattern. The exact winding pattern is proprietary, but its goal was to create a strong, cylindrical hull.

- Resin Matrix: The resin, typically an epoxy or similar thermosetting polymer, binds the fibers together and transfers stress between them. The type of resin and its curing process significantly impact the composite's overall strength and resistance to water ingress.

- Thickness:The exact thickness of the carbon fiber hull is proprietary information.

Titanium End Caps

The carbon fiber cylinder was capped at both ends with hemispherical domes made of titanium alloy, likely Ti-6Al-4V. Titanium is chosen for its excellent corrosion resistance and high strength-to-weight ratio, making it ideal for underwater applications. These end caps were crucial for sealing the submersible and providing attachment points for other components.

- Ti-6Al-4V: This specific alloy of titanium contains 6% aluminum and 4% vanadium. It's a workhorse alloy in aerospace and marine engineering due to its exceptional properties.

- Hemispherical Shape: Hemispheres are structurally efficient for resisting pressure. This shape evenly distributes the immense pressure exerted at depth.

- Welding: The titanium end caps were likely welded to flanges or fittings that could be bolted to the carbon fiber cylinder. The quality of these welds is paramount to the submersible's structural integrity.

View Port

The Titan featured a single, large viewport at one end. This was made of very thick, specialized acrylic. Acrylic is transparent, allowing for viewing, but needs to be incredibly robust to withstand the immense pressure at depth.

- Material: High-quality, pressure-rated acrylic.

- Thickness: Significantly thick to withstand deep-sea pressure.

- Shape: Conical or tapered to distribute pressure.

Other Components

Beyond the hull, other key components included:

- Ballast System: Used to control buoyancy, allowing the submersible to ascend and descend.

- Propulsion System: Electric motors and propellers provided maneuverability.

- Life Support System: Provided breathable air and removed carbon dioxide.

- Electronics and Control Systems: Managed navigation, communication, and other vital functions.

How It Worked

The Titan's design relied on the carbon fiber hull's ability to withstand immense compressive forces. As the submersible descended, the pressure increased dramatically. The carbon fiber cylinder, reinforced by the titanium end caps, was designed to resist this pressure without collapsing. The ballast system allowed the crew to control the submersible's depth. Internal electronics and control systems managed navigation, communication, and life support.

Theoretically, the carbon fiber hull would compress slightly under pressure, but within acceptable limits. Any flaws in the carbon fiber layup, the resin matrix, or the bonding between the carbon fiber and titanium could create points of weakness. Repeated pressure cycles could exacerbate these weaknesses, leading to material fatigue and, ultimately, failure.

Real-World Use – Basic Troubleshooting Tips (Hypothetical)

If you were *hypothetically* maintaining a submersible with a carbon fiber hull (which is beyond the scope of most DIYers), here are some potential issues and troubleshooting steps:

- Delamination: Inspect the hull surface for any signs of delamination (separation of layers in the composite). This could appear as blistering, cracking, or changes in the surface texture. Use non-destructive testing methods like ultrasonic testing to detect internal delamination.

- Water Ingress: Check for signs of water leakage around the titanium end caps and the viewport. Even small amounts of water ingress can indicate a compromised seal or crack.

- Corrosion: Inspect the titanium components for signs of corrosion, especially around welds. Use appropriate corrosion inhibitors to protect the metal surfaces.

- Sensor Readings: Monitor strain gauges and pressure sensors for any anomalies. Sudden changes in readings could indicate a structural problem.

- Acoustic Monitoring: Listen for unusual noises during pressure testing. Cracking or popping sounds could indicate material fatigue or damage.

Important: These are just hypothetical examples. Real submersible maintenance requires specialized equipment, training, and expertise.

Safety – Risky Components

The carbon fiber hull was undoubtedly the riskiest component of the Titan. Here's why:

- Unpredictable Failure Modes: Unlike metals, which tend to deform before failing, carbon fiber composites can fail catastrophically without warning. This makes it difficult to predict and prevent failures.

- Manufacturing Defects: Imperfections in the carbon fiber layup, resin curing, or bonding process can significantly weaken the hull. These defects may not be visible to the naked eye.

- Fatigue: Repeated pressure cycles can cause fatigue in the carbon fiber, leading to a gradual weakening of the material. Detecting this fatigue requires sophisticated monitoring techniques.

- Lack of Redundancy: The Titan had a single-hulled design, meaning there was no backup hull in case of failure.

Other risky components included the viewport (due to the potential for implosion) and the electrical systems (due to the risk of fire or electrical shock).

Technical Terms Defined

Carbon Fiber Composite: A material made by bonding together carbon fibers with a resin matrix. It is known for its high strength-to-weight ratio.

Titanium Alloy (Ti-6Al-4V): An alloy of titanium containing 6% aluminum and 4% vanadium. It is prized for its corrosion resistance and strength.

Delamination: The separation of layers in a composite material.

Resin Matrix: The polymer material that binds the fibers together in a composite.

Ballast System: A system used to control the buoyancy of a submersible.

Remember, the information here provides a basic understanding of the Titan's construction. Deep-sea engineering is a complex field requiring specialized knowledge and expertise. Consider this article a starting point for further research.

While we don't have the *actual* engineering diagrams (those are proprietary), this breakdown gives you a solid understanding of the materials involved and the principles behind the Titan's design. Understanding these materials is crucial to understanding the risks involved in deep-sea exploration.