What's A Transmission In A Car

Alright, let's dive deep into the heart of your car's drivetrain: the transmission. Whether you're planning a performance upgrade, diagnosing a frustrating shifting problem, or just looking to broaden your automotive knowledge, understanding your transmission is crucial. This article aims to provide a detailed explanation of what a transmission is, its key components, how it functions, and some practical troubleshooting tips.

Purpose of Understanding Transmission Diagrams and Function

Why bother learning about the inner workings of your transmission? Simple. Having a solid grasp of transmission operation can significantly aid in:

- DIY Repairs: From fluid changes to sensor replacements, knowing your transmission allows you to tackle basic maintenance and repairs yourself, saving money and gaining valuable experience.

- Accurate Diagnosis: When your car isn't shifting right, understanding the transmission's role helps you pinpoint the problem more effectively, avoiding unnecessary and costly mechanic visits.

- Informed Upgrades: Planning a performance boost? Knowing your transmission's capabilities and limitations is vital for choosing the right upgrades and avoiding potential damage.

- General Knowledge: Even if you don't plan on wrenching on your car, a deeper understanding of its systems is empowering and can help you make more informed decisions about its care and maintenance.

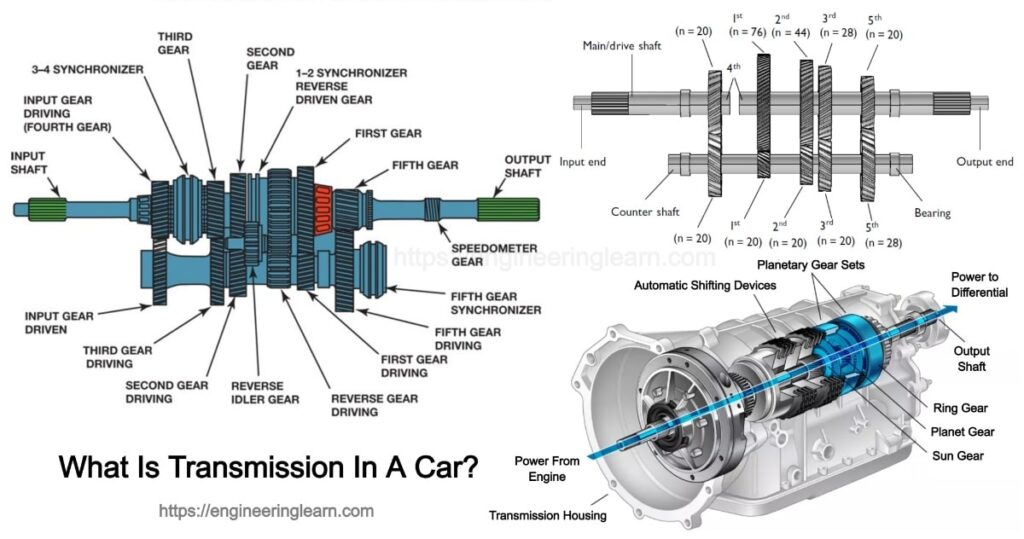

Key Specs and Main Parts

A transmission's primary function is to manage the engine's power output and deliver it effectively to the wheels. It does this by providing different gear ratios, allowing the engine to operate in its most efficient range regardless of the vehicle's speed. Let's break down the core components:

Essential Components:

- Bell Housing: The interface between the engine and the transmission. It houses the torque converter (in automatics) or the clutch (in manuals).

- Torque Converter (Automatic Transmissions): A fluid coupling that transfers engine power to the transmission. It multiplies torque at low speeds, providing smooth acceleration.

- Clutch (Manual Transmissions): A friction plate that connects and disconnects the engine from the transmission, allowing gear changes.

- Input Shaft: Receives power from the engine (via the torque converter or clutch) and transmits it into the transmission.

- Gears: A series of different-sized gears that provide various gear ratios. They are the heart of the transmission, responsible for multiplying torque and controlling speed. Common types include spur gears, helical gears, and planetary gears.

- Countershaft/Lay Shaft: An intermediate shaft that transfers power between the input and output shafts, providing the necessary gear ratios.

- Output Shaft: Delivers power from the transmission to the driveshaft, which then transmits it to the wheels.

- Valve Body (Automatic Transmissions): A complex hydraulic control system that directs fluid pressure to engage different gears.

- Solenoids (Automatic Transmissions): Electrically controlled valves that control the flow of hydraulic fluid in the valve body, enabling automated gear changes.

- Transmission Fluid: Lubricates the moving parts, cools the transmission, and provides hydraulic pressure for shifting in automatic transmissions.

- Differential: Though technically not *part* of the transmission, it is often integrated into the transaxle on front-wheel-drive vehicles. It allows the wheels to rotate at different speeds during turns.

Key Specs to Consider:

- Gear Ratios: The numerical relationship between the input and output speeds for each gear. A higher gear ratio provides more torque at the wheels but lower speed, while a lower gear ratio provides less torque but higher speed.

- Transmission Type: Manual (MT), Automatic (AT), Continuously Variable Transmission (CVT), Dual-Clutch Transmission (DCT).

- Torque Capacity: The maximum amount of torque the transmission can handle without failure.

- Fluid Type: The specific type of transmission fluid recommended for your transmission. Using the wrong fluid can cause serious damage.

Understanding Transmission Diagram Symbols

Transmission diagrams, like any technical schematic, use standardized symbols to represent various components and connections. While specific symbols may vary slightly depending on the manufacturer and diagram type, here are some common representations:

- Lines: Solid lines typically represent mechanical connections, such as shafts and linkages. Dashed lines often indicate hydraulic lines or electrical wiring. The thickness of the line can sometimes indicate the size or capacity of the component it represents (e.g., a thicker line for a larger hydraulic line).

- Circles: Often used to represent gears or bearings. Shading or cross-hatching may indicate different types of gears or bearings.

- Rectangles: Can represent various components, such as valve bodies, solenoids, or control modules. Labels inside the rectangle will identify the specific component.

- Arrows: Indicate the direction of fluid flow or mechanical movement.

- Color Coding: Some diagrams use color coding to differentiate between different systems or fluids. For example, one color might represent hydraulic fluid, while another represents electrical wiring. Refer to the diagram's legend for the specific color codes used.

- Hydraulic Symbols: Valves (check valves, spool valves, etc.), pumps, accumulators, and other hydraulic components have specific symbols. These are essential to learning if you're delving into automatic transmission repair.

How It Works: A Simplified Explanation

Let's break down the operation of both manual and automatic transmissions.

Manual Transmissions:

In a manual transmission, the driver selects the desired gear using a gear lever. This movement engages a specific set of gears, connecting the input shaft to the output shaft through a chosen gear ratio. The clutch is used to disconnect the engine from the transmission during gear changes, allowing the driver to smoothly select the desired gear. The driver manually controls gear selection and clutch engagement.

Automatic Transmissions:

Automatic transmissions use a torque converter to transfer power from the engine to the transmission. The torque converter allows the engine to continue running even when the vehicle is stopped. Gear changes are controlled automatically by the valve body, which uses hydraulic pressure to engage different sets of gears. The valve body is controlled by a combination of mechanical and electronic components, including solenoids that are activated by the transmission control unit (TCU). The TCU monitors various sensors, such as vehicle speed, engine load, and throttle position, to determine the optimal gear for the current driving conditions.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting tips for common transmission problems:

- Slipping Gears: The engine revs up without a corresponding increase in vehicle speed. This can be caused by worn clutch plates (manual), low transmission fluid (automatic), or a faulty valve body (automatic).

- Rough Shifting: Jerky or harsh gear changes. This can be caused by low transmission fluid, a worn clutch (manual), a faulty solenoid (automatic), or a damaged synchronizer (manual).

- Delayed Engagement: A delay between selecting a gear and the transmission engaging. This can be caused by low transmission fluid, a faulty valve body (automatic), or internal transmission damage.

- Unusual Noises: Grinding, whining, or clunking noises coming from the transmission. These noises can indicate worn bearings, damaged gears, or other internal damage.

- Check Engine Light: Transmission problems can sometimes trigger the check engine light. Use an OBD-II scanner to retrieve the trouble codes and diagnose the issue.

Important Note: Always check the transmission fluid level and condition as a first step in troubleshooting any transmission problem. Low or dirty fluid can cause a wide range of issues.

Safety Considerations

Working on transmissions involves potential hazards. Here are some key safety precautions:

- High Pressure: Automatic transmissions contain high-pressure hydraulic fluid. Be extremely careful when disconnecting hydraulic lines, as the fluid can spray out with considerable force.

- Heavy Components: Transmissions are heavy. Use proper lifting equipment and techniques to avoid injury.

- Hot Surfaces: The transmission can get very hot during operation. Allow it to cool down before working on it.

- Sharp Edges: Be careful of sharp edges on transmission components. Wear gloves to protect your hands.

- Eye Protection: Always wear safety glasses when working on a transmission to protect your eyes from flying debris.

- Proper Support: When removing the transmission, ensure the vehicle is properly supported with jack stands on a level surface.

Riskly Components: The torque converter stores significant energy even when the engine is off, so proper handling is crucial. The valve body is complex and sensitive; disassembly should only be attempted by experienced individuals. Finally, any components containing springs can release suddenly and with force, so extreme caution is required.

With a solid understanding of the principles covered here, coupled with careful study of your transmission's specific diagram, you'll be well-equipped to tackle a range of maintenance, diagnostic, and even performance enhancement tasks. Remember to always prioritize safety and consult with a qualified mechanic when in doubt.

You can download a sample transmission diagram to get a head start. Good luck!