What's The Transmission In A Car

Let's talk transmissions. If you're an experienced DIYer or modder, you already know that the engine provides the power, but the transmission is what gets that power to the wheels in a usable way. Understanding how your transmission works, its key components, and basic troubleshooting can save you a lot of money and keep you on the road. We'll be diving into the inner workings, specs, and common issues you might encounter.

Purpose of Understanding Your Transmission

Why bother understanding the transmission? Simple: knowledge is power (pun intended!). Understanding your transmission enables you to:

- Diagnose problems: Identify the source of that strange noise or slipping gear.

- Perform basic maintenance: Change the fluid correctly, inspect for leaks, and prevent major issues.

- Plan modifications: Choose the right transmission for a performance build or understand the limitations of your current one.

- Save money on repairs: A little DIY knowledge can help you avoid unnecessary trips to the mechanic for minor issues.

Having a solid grasp of transmission principles will not only allow you to perform preventive work, but also help to more informed decision making when talking with a mechanic.

Key Specs and Main Parts

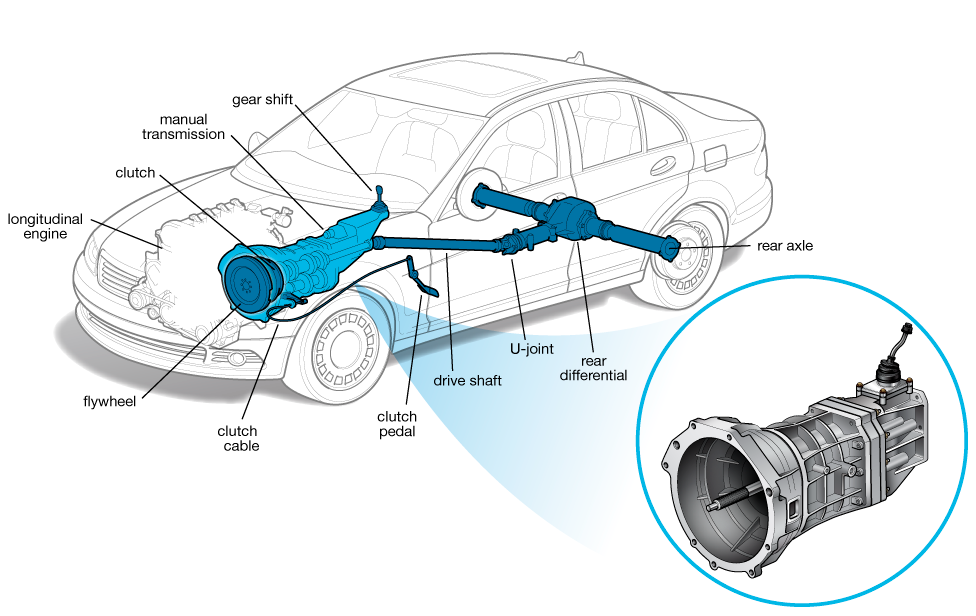

Let's break down the key components of a typical automotive transmission. We'll focus on both manual and automatic transmissions, highlighting their differences.

Manual Transmission

A manual transmission, sometimes called a stick shift, relies on the driver to select the appropriate gear ratio.

- Input Shaft: Receives power directly from the engine via the clutch.

- Clutch: Disconnects the engine from the transmission, allowing for gear changes. Crucial for smooth operation.

- Gears: A series of gears of different sizes, each providing a different gear ratio.

- Output Shaft: Delivers power from the transmission to the driveshaft.

- Synchronizers (Synchros): Match the speeds of the gears before engagement, preventing grinding. These wear out over time.

- Shift Forks: Move the synchronizers to engage the desired gear.

Automatic Transmission

An automatic transmission uses a hydraulic system and a complex arrangement of gears and clutches to automatically select the optimal gear ratio. The main components are:

- Torque Converter: Replaces the clutch in a manual transmission. It uses fluid to transmit power from the engine to the transmission, allowing the engine to continue running even when the wheels are stopped.

- Planetary Gear Sets: A complex arrangement of gears that provides different gear ratios.

- Clutches and Bands: Engage and disengage different planetary gear sets to change gears. Hydraulically actuated.

- Valve Body: The "brain" of the automatic transmission. It controls the flow of hydraulic fluid to the clutches and bands, determining when to shift gears.

- Transmission Control Module (TCM): An electronic control unit that monitors various sensors (speed, throttle position, etc.) and controls the valve body to optimize shifting.

Key Specs to Consider:

- Gear Ratios: The ratio between the engine speed and the output shaft speed for each gear. Lower gears provide more torque, while higher gears provide better fuel economy.

- Torque Capacity: The maximum amount of torque the transmission can handle without failing. Crucial for performance applications.

- Number of Gears: More gears generally mean better fuel economy and smoother acceleration.

- Transmission Fluid Type: Using the wrong fluid can damage the transmission. Refer to your owner's manual.

How It Works

Manual Transmission Operation

The driver presses the clutch pedal to disengage the engine. The shifter then selects the desired gear, moving the shift fork which engages a synchronizer to match the speed of the selected gear to the output shaft. Once the speeds are matched, the gear is engaged, and the clutch pedal is released, transmitting power through the selected gear ratio.

Automatic Transmission Operation

The torque converter multiplies torque at low speeds. The valve body, controlled by the TCM, uses hydraulic pressure to engage and disengage clutches and bands, shifting between gears based on engine load, vehicle speed, and driver input. Shift quality and timing is controlled by the TCM.

Real-World Use – Basic Troubleshooting Tips

Here are some common transmission problems and potential solutions:

- Slipping Gears (Both): Engine revs high, but the vehicle doesn't accelerate properly. In a manual, this could be a worn clutch. In an automatic, it may indicate worn clutches or low fluid.

- Rough Shifting (Both): Jerky or harsh gear changes. In a manual, could be worn synchronizers. In an automatic, might be a valve body issue or low fluid.

- Noise (Both): Whining, grinding, or clunking sounds. Could indicate worn bearings or gears.

- Leaks (Both): Transmission fluid leaks can lead to low fluid levels and damage. Check for leaks around seals and gaskets.

- Check Engine Light (Automatic): A trouble code related to the transmission is stored. Use an OBD-II scanner to retrieve the code and diagnose the problem.

Basic Checks:

- Fluid Level: Check the transmission fluid level regularly. Low fluid is a common cause of problems.

- Fluid Condition: Check the color and smell of the fluid. Dark, burnt-smelling fluid indicates overheating and wear.

- External Inspection: Look for leaks, cracks, or damage to the transmission housing.

Safety

Working on transmissions involves several safety risks:

- High Temperatures: Transmissions can get very hot. Allow the transmission to cool down before working on it.

- Heavy Components: Transmissions are heavy and awkward to handle. Use proper lifting equipment and techniques.

- Hydraulic Pressure (Automatic): Automatic transmissions operate under high hydraulic pressure. Relieve pressure before disconnecting lines.

- Sharp Edges: Transmission components can have sharp edges. Wear gloves to protect your hands.

- Flammable Fluids: Transmission fluid is flammable. Work in a well-ventilated area and avoid sparks or open flames.

Critical Safety Notes:

- Always disconnect the negative battery cable before working on any electrical components.

- Support the vehicle securely on jack stands before working underneath it.

- Use eye protection when working with fluids or compressed air.

Remember, if you're uncomfortable with any aspect of transmission repair, it's best to consult a qualified mechanic.