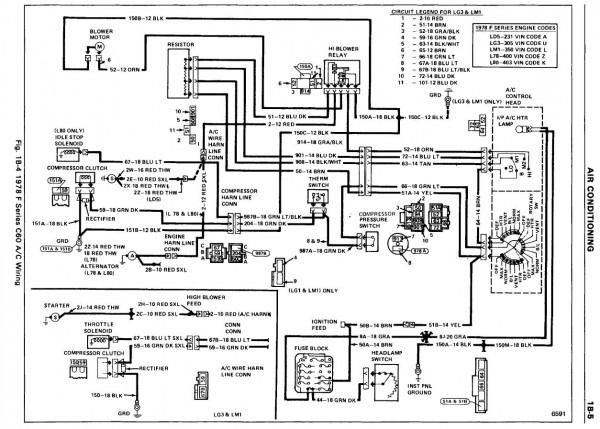

1980 Pontiac Firebird Trans Am Dash Wiring Diagram

So, you're diving into the dash wiring of a 1980 Pontiac Firebird Trans Am? Excellent! This is a rewarding, if sometimes challenging, task. Whether you're tracing a short, installing a new stereo, or simply trying to understand how everything connects, having a good grasp of the wiring diagram is crucial. This guide will walk you through the essential elements of the 1980 Trans Am dash wiring diagram, assuming you have some existing automotive experience.

Purpose of the Wiring Diagram

Why bother with the diagram at all? Well, the 1980 Trans Am's dash wiring is a complex network. It controls everything from your gauges and lights to the radio and climate control. The wiring diagram serves as a roadmap, allowing you to:

- Diagnose electrical problems: Precisely locate faulty circuits and components.

- Perform repairs: Correctly rewire damaged sections without guessing.

- Install aftermarket accessories: Safely integrate new devices like stereos, alarms, or gauges.

- Understand the system: Gain a deeper knowledge of your car's electrical system.

- Avoid further damage: Prevents accidentally shorting something out during modifications.

Key Specs and Main Parts of the '80 Trans Am Dash Wiring

The 1980 Trans Am utilizes a 12-volt DC electrical system. This is standard for most vehicles of that era. The dash wiring incorporates several key components:

- Power Source: The battery provides the initial power. A large gauge wire (usually red) connects the battery's positive terminal to the starter and the power distribution block in the engine bay.

- Ignition Switch: This is the central control point. It activates various circuits depending on the key position (OFF, ACC, RUN, START).

- Fuse Box/Block: This protects circuits from overloads. Each fuse is rated for a specific amperage. Blowing a fuse indicates a problem in that circuit. The under-dash fuse box is where you'll find circuits specific to dash components.

- Wiring Harness: A collection of wires bundled together for organization and protection. The main dash harness connects to various sub-harnesses for individual components.

- Ground Connections: All circuits require a ground connection (usually connected to the chassis). Poor grounds are a common cause of electrical problems. Clean, tight connections are essential.

- Switches: Controls for lights, wipers, climate control, etc. These switches open or close circuits to activate the corresponding components.

- Gauges: Voltmeter, oil pressure, temperature, fuel gauge, and speedometer (which is often mechanically driven but has electrical components for lighting).

- Lights: Instrument panel lights, warning lights, and indicator lights.

- Radio/Stereo: An entertainment system (if factory or aftermarket is installed).

- Climate Control: Heater and (optional) air conditioning controls.

- Wipers/Washers: Controls and motor for the windshield wipers and washers.

Understanding Wiring Diagram Symbols

The wiring diagram uses a standardized set of symbols to represent electrical components and connections. Let's break down some common ones:

- Lines: Solid lines represent wires. Dashed lines may indicate shielding or grounding. Line thickness doesn't generally denote wire gauge, so refer to the diagram's wire size callouts.

- Colors: Wires are color-coded (e.g., Red, Black, Blue, Yellow). The diagram will include a color code legend. Trace circuits by following the color of the wire. Sometimes wires will have a stripe (e.g., Red/White stripe).

- Circles with Numbers: Represent connection points, often numbered for easy identification.

- Squares: Generally represent switches or relays. The internal configuration shows how the switch connects different circuits.

- Rectangles: Can represent various components, such as sensors, modules, or the radio. The diagram should label what each rectangle represents.

- Zigzag Lines: Indicate resistors.

- Coils: Represent inductors or solenoids (often part of a relay).

- Ground Symbol: Usually three horizontal lines decreasing in size, connected to the chassis.

- Fuses: Represented by a small, squiggly line inside a rectangle. The amperage rating will be indicated.

- Connectors: Various symbols represent connectors. They often indicate the number of pins in the connector.

How It Works: A Basic Circuit Example

Let's consider a simple example: the instrument panel lights. Power flows from the battery, through the ignition switch (when in the RUN or ACC position), through a fuse (protecting the circuit), to the headlight switch. When the headlight switch is turned to the "parking lights" or "headlights" position, it completes the circuit to the instrument panel lights. A rheostat (a variable resistor) in the headlight switch allows you to adjust the brightness of the lights. Finally, the lights are grounded to the chassis to complete the circuit. Without a good ground, even a perfectly functional circuit won't work.

Real-World Use: Basic Troubleshooting

Here are some basic troubleshooting steps using the wiring diagram:

- Identify the Problem: What's not working? Be specific. For example, "The fuel gauge doesn't work."

- Consult the Diagram: Locate the fuel gauge circuit on the wiring diagram. Identify all components in the circuit (power source, fuse, wiring, sender unit, gauge, ground).

- Check the Fuse: Is the fuel gauge fuse blown? If so, replace it. If it blows again immediately, there's a short in the circuit.

- Test for Power: Use a multimeter to check for voltage at the fuel gauge connector. If there's no power, trace the wiring back to the fuse box, checking for breaks or loose connections.

- Check the Ground: Ensure the fuel gauge and the sender unit have a good ground connection. Clean any corroded ground points.

- Isolate the Problem: If power and ground are good, the problem may be with the fuel gauge itself or the fuel tank sending unit. Test these components individually if possible.

Safety First! Working with Electrical Systems

Working with automotive electrical systems can be dangerous. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical system. This prevents accidental shorts and potential fires.

- Use Proper Tools: Use insulated tools designed for automotive electrical work.

- Work in a Well-Ventilated Area: Battery acid fumes can be harmful.

- Never Work on a Live Circuit: Unless absolutely necessary for testing, always disconnect the power source.

- Be Careful Around the Airbag System: If your Trans Am has airbags (some later models did), be extremely careful when working near the airbag control module and sensors. Disconnect the battery and wait at least 30 minutes before working near these components to prevent accidental deployment. Accidental airbag deployment can cause serious injury.

- Check for Shorts: Before reconnecting the battery, carefully inspect all wiring for shorts or damaged insulation.

- Replace Fuses with the Correct Amperage: Never use a fuse with a higher amperage rating than specified. This can overload the circuit and cause a fire.

The distributor and ignition system, although not part of the dash, deliver high voltage. Avoid contact with these components while the engine is running.

Working on your 1980 Pontiac Firebird Trans Am's dash wiring can seem daunting, but with a clear understanding of the wiring diagram and proper safety precautions, you can successfully diagnose and repair electrical problems. Remember to take your time, be methodical, and double-check your work. A little patience and a good wiring diagram can save you a lot of time and money.

And to get you started, we have a high-resolution digital copy of the 1980 Pontiac Firebird Trans Am dash wiring diagram ready for you to download. This detailed schematic will be your indispensable guide as you navigate the electrical intricacies of your classic ride.