1990 Chevy Truck Instrument Cluster Wiring Diagram

So, you're diving into the instrument cluster of your 1990 Chevy truck, huh? Whether you're troubleshooting a pesky gauge issue, planning a custom modification, or simply trying to understand how all those needles light up, having a clear understanding of the wiring diagram is absolutely critical. This isn’t just a random collection of wires; it's the central nervous system for a lot of the information you, as the driver, rely on. Let's break down the 1990 Chevy Truck Instrument Cluster Wiring Diagram and give you the knowledge you need to tackle your project with confidence. We'll explain the common components, how they're wired, what the symbols mean, and how to use this information for practical troubleshooting.

Purpose of Understanding the Wiring Diagram

Why bother with the wiring diagram in the first place? Well, think of it as the roadmap for your instrument cluster. It serves several vital purposes:

- Troubleshooting: When a gauge isn't working or a warning light is illuminated (or won't turn off!), the diagram helps you trace the electrical path, pinpointing breaks or short circuits.

- Repairs: If you're replacing damaged wires or components, the diagram ensures you reconnect everything correctly, avoiding further damage.

- Modifications: Planning to add aftermarket gauges or a different cluster altogether? Understanding the existing wiring is essential for safe and effective integration.

- Learning: It helps you understand the general workings of automotive electrical systems.

Key Specs and Main Parts of the Instrument Cluster

The 1990 Chevy truck instrument cluster is a relatively straightforward system, but it's still important to know the core components and their role:

- Gauges: These are the analog displays that show you critical information like:

- Speedometer: Displays vehicle speed.

- Tachometer: (If equipped) Displays engine RPM.

- Fuel Gauge: Shows fuel level.

- Temperature Gauge: Monitors engine coolant temperature.

- Oil Pressure Gauge: Indicates engine oil pressure.

- Voltmeter: Measures battery voltage.

- Warning Lights: These lights illuminate to alert you to potential problems. Examples include:

- Check Engine Light (CEL): Indicates a problem with the engine management system.

- Brake Warning Light: Indicates a problem with the braking system.

- Oil Pressure Warning Light: Illuminates when oil pressure is critically low.

- Battery Warning Light: Indicates a problem with the charging system.

- Printed Circuit Board (PCB): This board acts as the backbone of the cluster, providing a pathway for electrical signals to travel between components. It often incorporates flexible circuits (flex circuits) to connect parts in tight spaces.

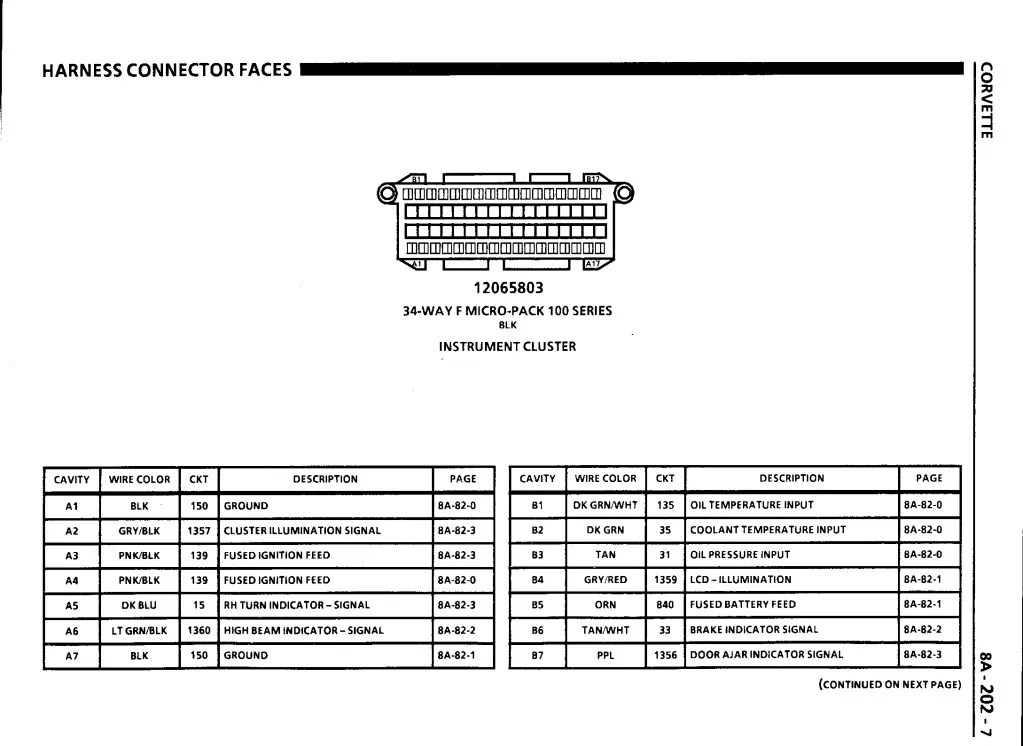

- Connectors: These are the physical connections that plug into the back of the cluster, bringing in power, ground, and signals from various sensors and modules in the vehicle.

- Voltage Regulator: The voltage regulator is a critical component that ensures the gauges receive a stable voltage supply. If this fails, the gauges may read incorrectly or erratically.

- Backlighting: Illuminates the gauges and indicators for nighttime visibility.

Understanding the Symbols

A wiring diagram is a symbolic language. Deciphering it is essential for proper use. Here are some common symbols you'll encounter in the 1990 Chevy truck instrument cluster wiring diagram:

- Solid Lines: Represent wires. The thickness of the line doesn't typically indicate wire gauge on these diagrams.

- Dashed Lines: May indicate a shielded wire or a ground connection. In other cases, dashed lines represent a connection or trace on the printed circuit board itself, rather than discrete wiring.

- Circles with Numbers or Letters: These often represent connector pins. The number or letter corresponds to a specific terminal on the connector.

- Resistors: Zigzag lines indicate resistors, which limit current flow.

- Capacitors: Two parallel lines represent capacitors, which store electrical energy.

- Ground Symbols: Represent connections to the vehicle's chassis ground.

- Diode Symbols: Triangle pointing to a line, indicates a diode (allows current flow in one direction).

- Color Codes: Wires are often identified by color codes (e.g., RED, BLU, GRN). The diagram key will translate these abbreviations. Always double-check the actual wire color in your truck, as variations can occur.

- Fuses: A small box with a line through it. Fuses protect circuits from overcurrent.

How It Works: The Electrical Flow

The instrument cluster is powered by the vehicle's electrical system. Here's a simplified overview of how it works:

- Power Supply: The cluster receives power from the battery, typically through a fused circuit. Often, there are separate power feeds for different functions (e.g., gauge operation and backlighting).

- Ground Connection: A solid ground connection is essential for proper operation. The cluster is typically grounded to the vehicle's chassis.

- Sensor Signals: Sensors throughout the engine and vehicle send signals to the cluster. For example:

- Speed Sensor: Sends a signal proportional to vehicle speed.

- Fuel Level Sensor: Sends a signal representing the amount of fuel in the tank.

- Temperature Sensor: Sends a signal based on engine coolant temperature.

- Oil Pressure Sensor: Sends a signal reflecting engine oil pressure.

- Signal Processing: The cluster's internal circuitry (mainly on the PCB) processes these signals and converts them into the appropriate gauge readings or warning light activations.

- Gauge Activation: The processed signals are then sent to the individual gauges, causing the needles to move to the corresponding positions.

- Warning Light Activation: When a sensor signal exceeds a predetermined threshold, the corresponding warning light is illuminated.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting steps you can take, armed with your wiring diagram:

- No Power to Cluster:

- Check the fuse that supplies power to the instrument cluster. Use a multimeter to verify that the fuse is good and that voltage is present at the fuse socket.

- Verify the ground connection. Clean and tighten the ground connection point.

- Use the wiring diagram to trace the power and ground wires from the fuse box and ground point to the cluster connector. Look for any breaks or loose connections.

- Gauge Not Working:

- Consult the wiring diagram to identify the wire connecting the gauge to the relevant sensor.

- Check the sensor itself. Use a multimeter to test the sensor's resistance. Refer to your truck's service manual for the correct resistance values.

- Inspect the wiring between the sensor and the cluster for damage or loose connections.

- If possible, temporarily swap the gauge with a known-good gauge from another cluster (if available). If the replacement gauge works, the original gauge is faulty.

- Warning Light Stays On:

- Use an OBD1 code reader to check for diagnostic trouble codes (DTCs). The code will give you a starting point for troubleshooting.

- Consult the wiring diagram to identify the wire connecting the warning light to the relevant sensor or module.

- Check the sensor or module for proper operation.

- Inspect the wiring between the sensor/module and the cluster for shorts to ground or opens in the circuit.

Safety First! Highlighting Risky Components

Working with automotive electrical systems can be dangerous. Always disconnect the negative battery cable before working on the instrument cluster. Some specific safety considerations include:

- Capacitors: Some capacitors can store a high voltage charge even after the power is disconnected. Use caution when handling the printed circuit board. It is always wise to ground them before proceeding.

- Fuses: Never replace a fuse with a higher amperage fuse. This can overload the circuit and cause a fire.

- Wiring: Be careful not to short-circuit any wires. This can damage the instrument cluster and other electrical components.

- Airbags: Although not directly related to the instrument cluster itself, be mindful of the location of any airbag components when working in the dashboard area. Accidental activation of an airbag can cause serious injury.

By taking the time to study the wiring diagram and following these tips, you'll be well-equipped to tackle a wide range of instrument cluster issues on your 1990 Chevy truck. Remember, patience and a methodical approach are key to success.

We have the complete 1990 Chevy Truck Instrument Cluster Wiring Diagram available for download. Having the complete file will aid you further in your repair or modification. Contact us for the download link.