2 Wire Solenoid Valve Wiring Diagram

If you're diving into automotive modifications, repairs, or even custom projects, understanding how a 2-wire solenoid valve works and how to wire it up is crucial. This guide breaks down the 2-wire solenoid valve wiring diagram, providing you with the knowledge to confidently tackle these projects. Whether you're replacing a faulty valve, implementing a new system, or simply expanding your automotive knowledge, this article is your starting point.

Purpose of Understanding the 2-Wire Solenoid Valve Wiring Diagram

Why bother learning about these diagrams? Several key reasons stand out:

- Repair and Replacement: Identifying wiring problems quickly and replacing a faulty solenoid valve becomes much easier.

- Custom Projects: Incorporating solenoids into custom automotive systems, like boost control, nitrous systems, or air suspension, requires a solid understanding of their wiring.

- Troubleshooting: Accurately diagnose electrical issues affecting your vehicle's performance.

- Learning: Expanding your automotive skillset empowers you to perform more maintenance and modifications yourself, saving time and money.

Key Specs and Main Parts

Before diving into the diagram itself, let's cover the key components and specifications involved:

- Solenoid Valve: The electromechanical device controls fluid or air flow. It contains a coil of wire that, when energized, creates a magnetic field, moving a plunger to open or close the valve.

- 2 Wires: This is the defining characteristic. One wire provides power (typically 12V in automotive applications), and the other provides the ground (return) path. The simplicity is both an advantage and a limitation.

- Voltage Rating: Typically 12V DC for automotive applications. Crucially, ensure the voltage supplied matches the solenoid's rating. Using the wrong voltage can damage the solenoid or prevent it from functioning correctly.

- Current Draw: The amount of current the solenoid consumes when energized. This affects wire gauge selection and circuit protection (fuse size).

- Resistance: Measured in ohms (Ω), the resistance of the solenoid coil is a critical parameter. A significantly higher or lower resistance than the specification indicates a potential problem with the coil (shorted or open).

- Diode (Flyback Diode): Often incorporated internally or externally, a diode protects the controlling circuit (ECU, relay, etc.) from voltage spikes generated when the solenoid coil is de-energized. These spikes, also known as Back EMF or flyback voltage, can damage sensitive electronics.

Symbols in a 2-Wire Solenoid Valve Wiring Diagram

Understanding the symbols is essential for reading and interpreting the diagram. Here's a breakdown of common symbols:

- Straight Lines: Represent wires. Thicker lines often indicate higher current carrying capacity.

- Dotted Lines: May indicate shielded wires or wires that are part of a harness.

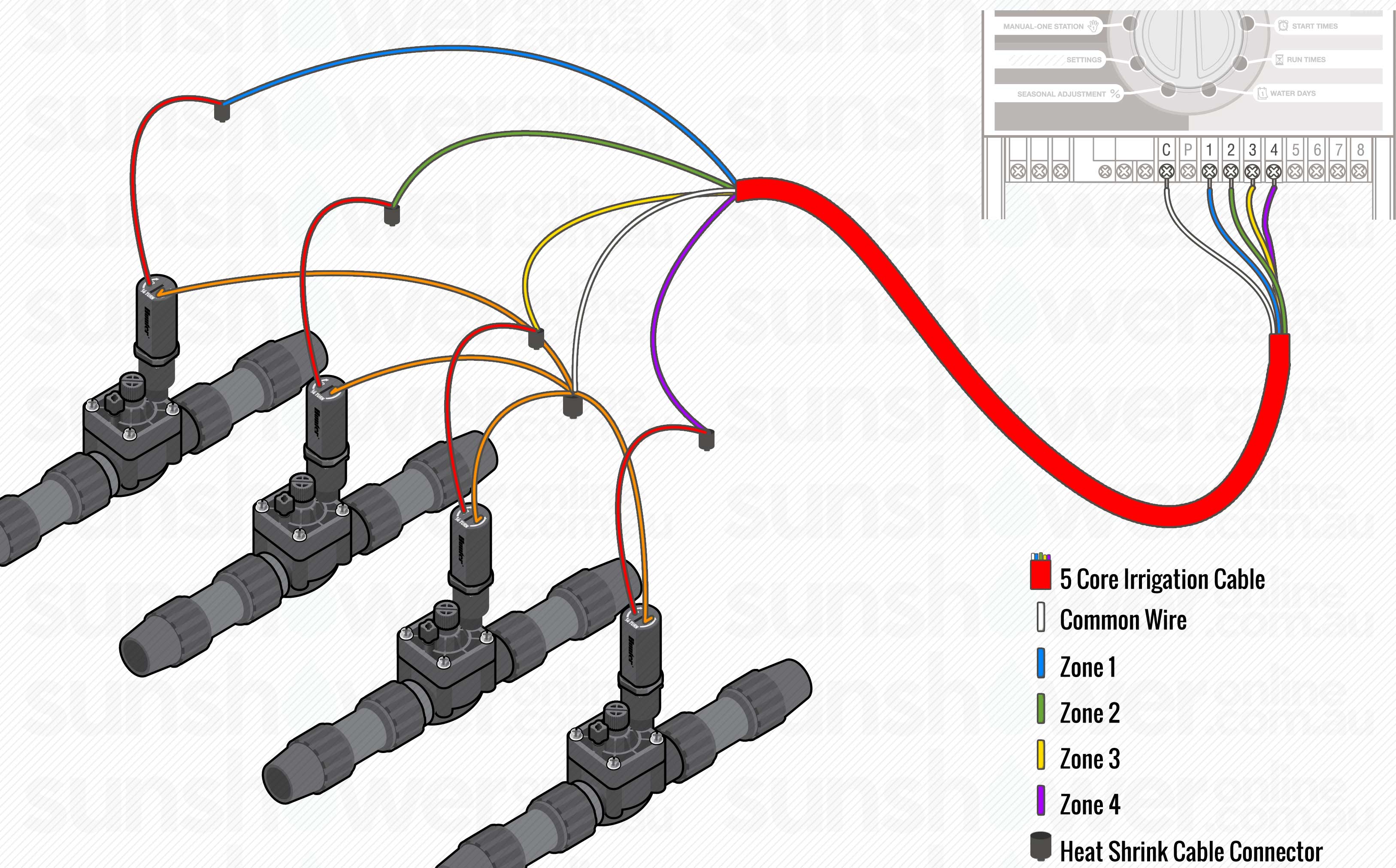

- Color Codes: Wires are typically color-coded for identification. Common colors include red (power), black (ground), and other colors for signal wires. The diagram should include a color key.

- Solenoid Symbol: Usually a rectangular box with a coil symbol inside, often with an arrow indicating the direction of flow.

- Ground Symbol: Typically represented by three descending horizontal lines, resembling an upside-down Christmas tree, or a 'T' shape.

- Fuse Symbol: A zigzag line within a rectangle or a simple line with a 'C' shape around it, protecting the circuit from overcurrent.

- Relay Symbol: Shows the relay coil and the switch contacts it controls. While a 2-wire solenoid can be directly powered, relays are often used to switch larger currents, protecting the control circuit.

- Diode Symbol: An arrow pointing to a vertical line. The arrow indicates the direction of conventional current flow. In a flyback diode, the arrow points towards the positive supply.

Example Color Codes:

B: Black, R: Red, W: White, G: Green, BL: Blue, Y: Yellow

How It Works

The operation of a 2-wire solenoid valve is relatively straightforward:

- Power Application: When 12V DC is applied to one wire and the other wire is connected to ground, a current flows through the solenoid coil.

- Magnetic Field Generation: The current flow creates a magnetic field inside the solenoid.

- Plunger Activation: This magnetic field pulls a plunger (a movable core) inside the solenoid.

- Valve Operation: The movement of the plunger either opens or closes the valve, allowing or blocking fluid or air flow. Whether the valve is normally open (NO) or normally closed (NC) determines its state when unpowered.

- De-energizing: When the power is removed, the magnetic field collapses. A spring (typically) returns the plunger to its original position, closing or opening the valve depending on its type.

The speed of operation (how quickly the valve opens or closes) is a key performance characteristic, often measured in milliseconds.

Real-World Use and Basic Troubleshooting

Let's look at some practical scenarios and troubleshooting tips:

- Valve Not Activating:

- Check Power and Ground: Use a multimeter to verify that 12V is present at the power wire when the solenoid is supposed to be active, and that the ground wire has a good connection to the vehicle chassis or ground point.

- Check the Fuse: A blown fuse is a common culprit. Replace the fuse with one of the correct amperage rating.

- Check Solenoid Resistance: Use a multimeter to measure the resistance across the solenoid terminals. A reading of zero ohms indicates a short circuit, while an infinite reading indicates an open circuit. Compare the measured resistance to the solenoid's specifications.

- Listen for a Click: If you apply power to the solenoid, you should hear a distinct "click" as the plunger moves. If you don't hear a click, the solenoid may be faulty.

- Valve Stuck Open or Closed:

- Mechanical Binding: Debris or corrosion can cause the plunger to stick. Try cleaning the valve.

- Damaged Plunger or Seal: The plunger or valve seat may be damaged, preventing proper sealing. Replacement is usually necessary.

- Electrical Noise/Interference:

A malfunctioning flyback diode can cause significant electrical noise in the system, potentially affecting other sensors or modules. Proper shielding of the solenoid wiring can also minimize interference.

Safety Considerations

Working with automotive electrical systems involves inherent risks. Here are some important safety precautions:

- Disconnect the Battery: Always disconnect the negative terminal of the battery before working on any electrical components. This prevents accidental shorts and electrical shocks.

- Use Proper Tools: Use insulated tools designed for automotive electrical work.

- Check Voltage Ratings: Ensure that the voltage of the power source matches the voltage rating of the solenoid valve.

- Protect Yourself: Wear safety glasses and gloves to protect yourself from potential hazards.

- High Current Components: Relays, solenoids, and wiring carrying high currents can get hot. Avoid touching these components immediately after they have been in operation.

- Flyback Voltage: Be aware of the flyback voltage generated when the solenoid is de-energized. Ensure a properly functioning flyback diode is in place to protect the controlling circuit.

Disclaimer: Incorrect wiring can damage your vehicle's electrical system or the solenoid valve itself. If you are not comfortable working with electrical systems, consult a qualified mechanic.

We have a detailed 2-wire solenoid valve wiring diagram file available for download. Understanding and correctly implementing the diagram is key to safe and effective automotive modifications and repairs.