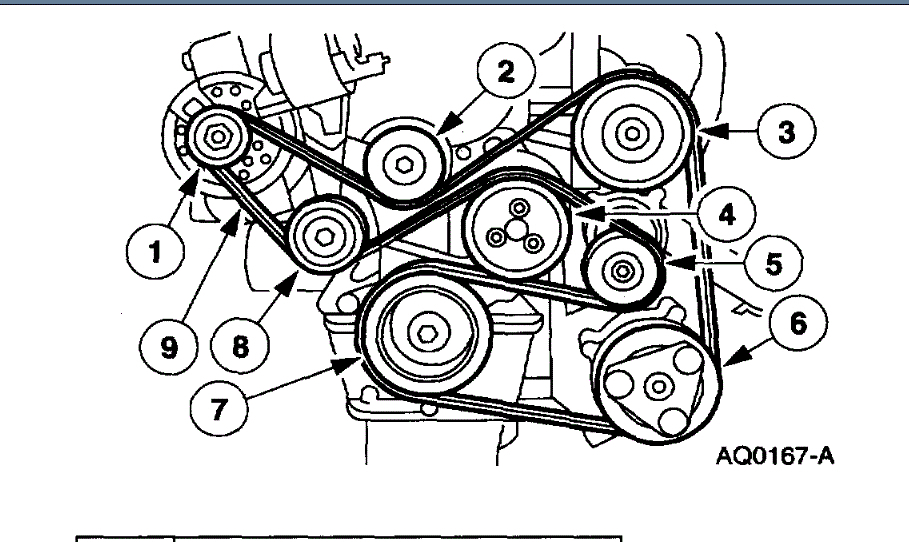

2004 Dodge Ram 1500 5.7 Hemi Serpentine Belt Diagram

Alright, let's dive into the serpentine belt system on your 2004 Dodge Ram 1500 with the 5.7L Hemi. This article will provide a detailed breakdown of the serpentine belt diagram, why it's essential, how it works, and some practical troubleshooting tips. We'll focus on equipping you with the knowledge to confidently tackle belt replacements, diagnose issues, and understand the critical role this seemingly simple component plays in your truck's operation.

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram is your roadmap to understanding the belt routing on your engine. It's invaluable for several reasons:

- Replacement: When replacing a worn or broken serpentine belt, the diagram ensures you route the new belt correctly. Incorrect routing can lead to component failure, poor performance, and even engine damage.

- Diagnosis: If you're experiencing squealing noises, power steering issues, or a lack of air conditioning, the diagram helps you inspect the belt and pulleys for damage or misalignment.

- Learning: Understanding the serpentine belt system allows you to grasp the relationship between various engine components and how they are driven.

- Preventative Maintenance: Being familiar with the system makes it easier to spot potential problems before they lead to costly repairs.

Key Specs and Main Parts

The 2004 Dodge Ram 1500 5.7L Hemi serpentine belt system consists of several key components. Understanding their function is crucial:

- Serpentine Belt: A single, long belt that drives multiple engine accessories. It's usually made of reinforced rubber.

- Crankshaft Pulley: Connected directly to the crankshaft, this pulley is the primary driver of the serpentine belt.

- Alternator Pulley: Driven by the serpentine belt to generate electricity for the vehicle's electrical system. The alternator recharges the battery and powers electrical components.

- Power Steering Pump Pulley: Driven by the serpentine belt to provide hydraulic pressure for power-assisted steering.

- Air Conditioning Compressor Pulley: Driven by the serpentine belt to compress refrigerant, which is essential for cooling the cabin air.

- Water Pump Pulley: Driven by the serpentine belt to circulate coolant through the engine and radiator, preventing overheating.

- Idler Pulley(s): Smooth pulleys that provide tension and guide the serpentine belt along its path. They don't drive any accessories.

- Tensioner Pulley: A spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. This is crucial for proper accessory operation and belt longevity. A failing tensioner can cause belt slippage and premature wear.

Symbols and Diagram Conventions

A typical serpentine belt diagram uses symbols and lines to represent the different components and belt path. Here’s a breakdown of common conventions:

- Solid Lines: Represent the serpentine belt itself. The thickness of the line doesn't usually indicate belt thickness, but the line clearly shows the belt's path.

- Pulleys: Usually depicted as circles or rounded shapes. Sometimes, the diagram will include a small icon to indicate the specific accessory (e.g., a lightning bolt for the alternator).

- Arrows: Indicate the direction of rotation for each pulley. Knowing the direction of rotation is vital when routing the belt.

- Text Labels: Pulleys are labeled with abbreviations (ALT for alternator, P/S for power steering, A/C for air conditioning, WP for water pump, CRK for crankshaft, IDL for idler, TEN for tensioner) to clearly identify each component.

- Color Coding (Rare): Some diagrams might use color coding to highlight specific sections of the belt path or identify components.

- Ribbed vs. Smooth Side: The diagram will show which side of the belt makes contact with each pulley (ribbed or smooth). This is critical for proper routing. Ribbed sections engage with grooved pulleys, while the smooth side usually contacts idler pulleys and the tensioner pulley.

How It Works

The serpentine belt system's operation is relatively straightforward. The crankshaft pulley, directly connected to the engine's crankshaft, rotates whenever the engine is running. This rotation is transferred to the serpentine belt, which then drives all the other accessory pulleys. The tensioner pulley maintains the correct belt tension, ensuring optimal grip and preventing slippage. Without the serpentine belt, the alternator wouldn't charge the battery, the power steering wouldn't function, the air conditioning wouldn't cool the cabin, and the water pump wouldn't circulate coolant, leading to catastrophic engine overheating.

Real-World Use: Basic Troubleshooting

Here are a few basic troubleshooting tips when dealing with your serpentine belt system:

- Squealing Noise: Often indicates a loose or worn belt. Check the belt for cracks, glazing (a shiny, smooth surface), or missing ribs. Inspect the tensioner pulley to ensure it's functioning correctly. A weak tensioner spring can cause the belt to slip.

- Belt Slippage: Can cause issues like a weak alternator output (dim headlights), poor power steering performance, or ineffective air conditioning. Check the belt tension and condition. Look for signs of oil or coolant contamination, which can reduce grip.

- Cracked or Frayed Belt: Indicates age and wear. Replace the belt immediately.

- Pulley Misalignment: Can cause premature belt wear and noise. Use a straight edge to check if the pulleys are properly aligned. Misalignment could be caused by a bent pulley bracket or a worn pulley bearing.

- Visual Inspection: Regularly inspect the belt for signs of wear, cracks, or damage. A good visual inspection can catch potential problems before they lead to complete failure.

Safety Considerations

Working on the serpentine belt system requires caution. Here are a few safety points to remember:

- Engine Off: Always ensure the engine is completely off and the key is removed from the ignition before working on the serpentine belt system.

- Battery Disconnect: Disconnecting the negative battery terminal is a good practice to prevent accidental starting or electrical shorts.

- Hot Engine: Avoid working on the system immediately after the engine has been running, as components can be extremely hot.

- Moving Parts: Be aware of the potential for moving parts if the engine is accidentally started. Keep hands and clothing clear. The cooling fan driven by the engine can cause serious injury.

- Proper Tools: Use the correct tools for the job, especially when releasing the tension on the tensioner pulley. Avoid using improvised tools that could slip and cause injury.

Diagram Download

You can download the serpentine belt diagram for the 2004 Dodge Ram 1500 5.7L Hemi. Having this file readily available will make future repairs and maintenance much easier.