2005 Nissan Altima 2.5 Belt Diagram

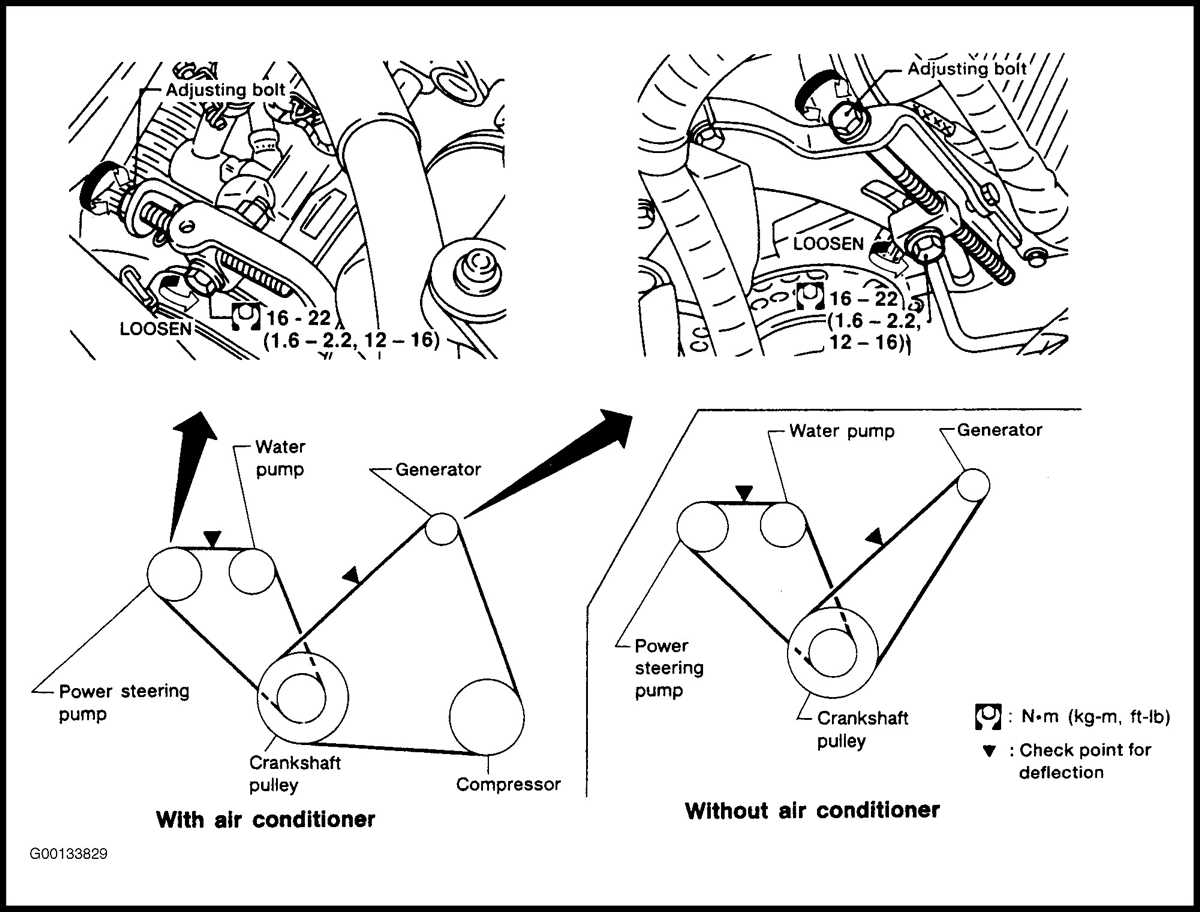

Alright, let's dive into the serpentine belt diagram for a 2005 Nissan Altima with the 2.5L engine. This article is geared towards those of you who are comfortable wrenching on your own car, and maybe even considering tackling a belt replacement or diagnosing a squealing noise under the hood. Having a clear understanding of the belt routing is absolutely essential, so let's get started.

Purpose of the Belt Diagram

The serpentine belt diagram is your roadmap for the engine's accessory drive system. Without it, replacing a belt can become a frustrating puzzle. More specifically, the belt diagram serves several crucial purposes:

- Correct Belt Routing: The primary function is to show the precise path the serpentine belt takes around all the pulleys. Improper routing can lead to component failure and serious engine damage.

- Troubleshooting: When dealing with issues like belt slippage, noise, or component malfunction (alternator not charging, power steering failure, etc.), the diagram helps you visually inspect the system and identify potential problems.

- Component Identification: It clearly labels all the components driven by the belt, allowing you to quickly identify what each pulley is connected to.

- Preventative Maintenance: Knowing the routing allows you to inspect the belt for wear and tear more easily.

Key Specs and Main Parts

Before we dissect the diagram, let's talk about the heart of the system and key technical specs for the 2005 Altima 2.5L:

- Engine: QR25DE (2.5L Inline-4).

- Belt Type: Serpentine belt - a single, continuous belt that drives multiple engine accessories.

- Common Belt Length: Typically around 84-85 inches, but it's always best to double-check the part number for your specific vehicle. Refer to your vehicle's owner's manual or parts catalog for the precise belt length.

- Tensioner: Automatic tensioner – uses a spring-loaded mechanism to maintain proper belt tension.

Here's a breakdown of the components that the serpentine belt typically drives on the 2005 Altima 2.5L:

- Crankshaft Pulley (Crank Pulley): The driven pulley connected to the engine's crankshaft, providing the rotational power to the belt.

- Alternator Pulley: Drives the alternator, which charges the battery and powers the electrical system.

- Power Steering Pump Pulley: Powers the power steering system, providing assistance for steering.

- Air Conditioning Compressor Pulley: Drives the AC compressor, responsible for cooling the cabin.

- Idler Pulley(s): Smooth, non-driven pulleys used to guide the belt and maintain proper wrap angle around other pulleys. These are crucial for ensuring the belt doesn't slip.

- Tensioner Pulley: Part of the automatic tensioner assembly, provides tension to the belt.

Symbols: Deciphering the Diagram

Understanding the symbols used on the diagram is crucial for accurate interpretation. Here's a typical breakdown:

- Solid Lines: Represent the path of the belt itself. The thicker the line, the easier it will be to see on the diagram.

- Dashed Lines (Sometimes): Might indicate the hidden portion of the belt behind another component. Pay close attention to these!

- Arrows: Indicate the direction of belt travel around each pulley. This is critical for ensuring correct routing.

- Circles: Represent the pulleys themselves. They might be labeled with abbreviations (ALT for alternator, P/S for power steering, A/C for air conditioning, CRANK for crankshaft).

- Text Labels: Clarify what each pulley drives (e.g., "Alternator," "Power Steering Pump").

- Tensioner Symbol: The tensioner pulley often has a unique symbol, sometimes resembling a spring or arm, indicating its role in maintaining belt tension.

Sometimes, diagrams use color-coding, but this is less common. If your diagram is color-coded, make sure you understand what each color represents. Generally, it highlights important aspects or differentiates sections of the drive system.

How It Works: The Serpentine System

The serpentine belt system is a brilliant piece of engineering simplicity. The crankshaft provides the rotational force. This force is then transferred by the serpentine belt, weaving around the various pulleys to drive the accessories. The automatic tensioner is key; it applies constant pressure to the belt, preventing slippage and ensuring optimal performance of all driven components. The tensioner is also responsible for compensating for belt stretch as it ages.

The beauty of the serpentine system lies in its efficiency and simplicity compared to older multi-belt setups. A single belt does the job of multiple belts, reducing maintenance and increasing reliability.

Real-World Use: Troubleshooting Tips

Okay, time to put this knowledge to practical use. Here are a few basic troubleshooting scenarios and how the belt diagram can help:

- Squealing Noise: A squealing noise, especially when the engine is cold or under load (e.g., turning the steering wheel at low speeds), often indicates belt slippage. Use the diagram to:

- Visually inspect the belt for cracks, glazing, or fraying.

- Check the tensioner for proper movement and spring tension.

- Ensure the belt is properly seated on all pulleys.

- Alternator Not Charging/Power Steering Failure/AC Not Working: If one of these accessories is malfunctioning, the diagram allows you to quickly isolate the problem. If the belt is intact and properly routed, the issue is likely with the accessory itself. If the belt is broken, then the pulley is not spinning, and the accessories don't work.

- Belt Replacement: The diagram is absolutely indispensable for belt replacement. Before removing the old belt, carefully study the diagram and even take pictures of the belt routing for reference. This will prevent headaches and ensure you reinstall the new belt correctly.

- Incorrect Routing After Repair: If you've recently had work done on your car and notice issues, double-check the belt routing against the diagram. It's possible the belt was installed incorrectly.

Important Note: When diagnosing belt-related issues, also inspect the pulleys themselves. A damaged or misaligned pulley can cause premature belt wear and slippage. Check for wobbling, play, or damage to the pulley surface.

Safety Considerations

Working around a running engine can be dangerous. The serpentine belt system is no exception. Here are some critical safety precautions:

- Never work on the belt system with the engine running! The rotating components can cause severe injury.

- Disconnect the negative battery cable before working on any electrical components. The alternator, in particular, carries high voltage.

- Keep loose clothing, hair, and jewelry away from the belt and pulleys.

- Use the correct tools. A serpentine belt tool (a special wrench designed to release the tension on the tensioner) is highly recommended for belt replacement.

- Be aware of hot engine components. Allow the engine to cool down before working on the belt system.

- Eye protection is a must! Flying debris is always a possibility.

The automatic tensioner stores significant spring energy. When releasing the tensioner to remove or install the belt, be sure to do so slowly and carefully to avoid injury.

With the right tools, safety precautions, and this guide, you'll have a good foundation for working with the serpentine belt system on your 2005 Nissan Altima 2.5L. Remember to double-check everything, and when in doubt, consult a professional mechanic. Good luck!

We have a detailed 2005 Nissan Altima 2.5L Serpentine Belt Diagram file ready for you. You can download it using the link below.