2005 Pontiac Grand Prix Belt Diagram

Alright, let's dive into the serpentine belt system of the 2005 Pontiac Grand Prix. Whether you're tackling a repair, upgrading components, or just trying to understand how your engine's accessories are driven, understanding the belt diagram is absolutely crucial. We're going to break down everything you need to know, from the individual components to real-world troubleshooting tips. Knowing this is like having a secret weapon when your Grand Prix starts acting up.

Why Bother with the Belt Diagram?

The belt diagram isn't just some pretty picture – it's your roadmap to the serpentine belt system. Here's why it's so important:

- Repairs and Maintenance: Replacing a worn or broken belt is a common maintenance task. The diagram shows you the correct belt routing, ensuring your accessories are powered properly. Incorrect routing can lead to component damage and performance issues.

- Troubleshooting: A squealing belt, overheating issues, or a non-functioning power steering system can often be traced back to a problem with the belt or its associated components. The diagram helps you identify potential problem areas.

- Upgrades and Modifications: Thinking about adding a supercharger or other accessory that relies on the belt system? The diagram will help you plan your modifications and ensure proper belt length and routing.

- Understanding Your Engine: For the mechanically inclined, understanding the belt system provides valuable insight into the overall operation of your engine. It allows you to see how different components work together to keep your car running smoothly.

Key Specs and Main Parts

The 2005 Grand Prix, depending on the engine, will have variations in the specific belt routing. We'll focus on the most common setups – the 3.8L V6 (L36 and L26) and the 5.3L V8 (LS4).

Common Components:

- Crankshaft Pulley (Harmonic Balancer): The main pulley driven directly by the engine's crankshaft. It's the starting point for the serpentine belt's journey.

- Alternator Pulley: Powers the alternator, which charges the battery and provides electrical power to the car's systems.

- Power Steering Pump Pulley: Provides hydraulic pressure for the power steering system, making steering easier.

- Air Conditioning Compressor Pulley: Powers the AC compressor, which cools the air in the cabin.

- Water Pump Pulley: Circulates coolant throughout the engine to prevent overheating.

- Tensioner Pulley: Maintains proper tension on the serpentine belt, preventing slippage and ensuring optimal performance of all driven accessories. A spring-loaded mechanism typically provides the tension.

- Idler Pulley: Used to guide the belt around the various components and maintain proper wrap angle on other pulleys. They are smooth and do not drive any accessories.

- Serpentine Belt: The heart of the system. A single, continuous belt that wraps around all the pulleys, transferring power from the crankshaft to the accessories.

Belt Length: The belt length varies depending on the engine and whether or not the vehicle is equipped with certain options (like heavy-duty cooling). It's crucial to use the correct belt length for your specific vehicle. This information is usually found on a sticker in the engine compartment or in the owner's manual. Always double-check the part number before installation.

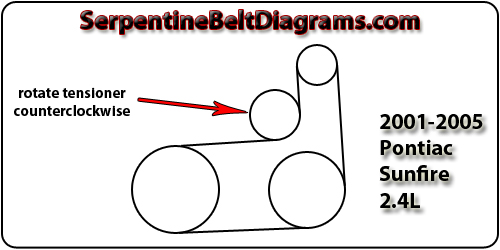

Decoding the Diagram: Symbols and Conventions

Belt diagrams use a standardized set of symbols and conventions to convey information clearly. Here's what to look for:

- Solid Lines: Represent the path of the serpentine belt. The thickness of the line doesn't usually have any specific meaning.

- Pulleys: Represented as circles. Some diagrams may show the pulley with a simple circle, while others might include a simplified representation of the pulley's design (e.g., grooves for a ribbed pulley).

- Arrows: Indicate the direction of belt travel. Following the arrows is crucial for proper belt routing.

- Component Labels: Each pulley will be labeled with an abbreviation or a full name indicating the component it drives (e.g., ALT for Alternator, P/S for Power Steering).

- Tensioner Symbol: The tensioner pulley is often depicted with a spring-like symbol to indicate its spring-loaded mechanism.

- Idler Pulley Symbol: An idler pulley may be shown with no labels, or specifically called out as “IDLER”. It will also have no connections to accessories other than belt routing.

Color Coding: While not always present, some diagrams may use color coding to highlight different sections of the belt path or to distinguish between different versions of the system. If colors are used, a legend will typically be provided.

How It Works: The Serpentine Belt System in Action

The serpentine belt system is relatively straightforward in its operation. The crankshaft pulley, powered by the engine, drives the serpentine belt. As the belt rotates, it transfers power to each of the accessory pulleys. The tensioner pulley maintains constant tension on the belt, ensuring that it doesn't slip and that all the accessories are driven at their proper speeds.

The belt is designed to be a friction drive. This means it relies on the friction between the belt and the pulleys to transfer power. Therefore, a correctly tensioned and undamaged belt is crucial for proper operation.

Real-World Use: Troubleshooting Tips

Here are some common issues you might encounter and how the belt diagram can help:

- Squealing Belt: A squealing belt is often a sign of slippage. Use the diagram to check the tensioner pulley. Is it moving freely? Is it properly tensioning the belt? Also, inspect the belt for wear, cracks, or glazing.

- Overheating: If the water pump isn't being driven properly (due to a loose or broken belt), the engine can overheat. Use the diagram to confirm the belt is routed correctly around the water pump pulley.

- Power Steering Failure: If the power steering pump isn't being driven, you'll notice a significant increase in steering effort. Again, use the diagram to check the belt routing and tension.

- Alternator Problems: A malfunctioning alternator can result in a dead battery or electrical system issues. Confirm the belt is properly driving the alternator pulley.

Belt Routing After Replacement: After replacing the belt, double-check the routing against the diagram. Even a slight deviation can cause serious problems. Run the engine briefly and re-inspect the belt to ensure it's seated properly on all pulleys.

Safety First! High-Risk Components

Working on the serpentine belt system can be dangerous if you're not careful. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical components, including the alternator.

- Engine Off and Cool: Never work on the belt system while the engine is running or hot. Give the engine ample time to cool down before starting any repairs.

- Keep Fingers Clear: Be extremely careful when working near moving parts. Keep your fingers and clothing clear of the belt and pulleys, especially when starting the engine to test your work.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

The Tensioner: The tensioner pulley is under spring pressure. Use the correct tool (usually a serpentine belt tool or a wrench) to relieve the tension before removing or installing the belt. Improper handling can cause injury.

Remember, safety is paramount. If you're not comfortable performing these repairs yourself, seek the assistance of a qualified mechanic.

Understanding the serpentine belt diagram for your 2005 Pontiac Grand Prix is a valuable skill for any DIY mechanic. It allows you to diagnose problems, perform routine maintenance, and even tackle more complex modifications. By understanding the components, symbols, and operation of the system, you can keep your Grand Prix running smoothly for years to come.

We have the full resolution file of the 2005 Pontiac Grand Prix belt diagram. You can download it here. (Replace # with actual link).