2006 Dodge Ram 1500 5.7 Belt Diagram

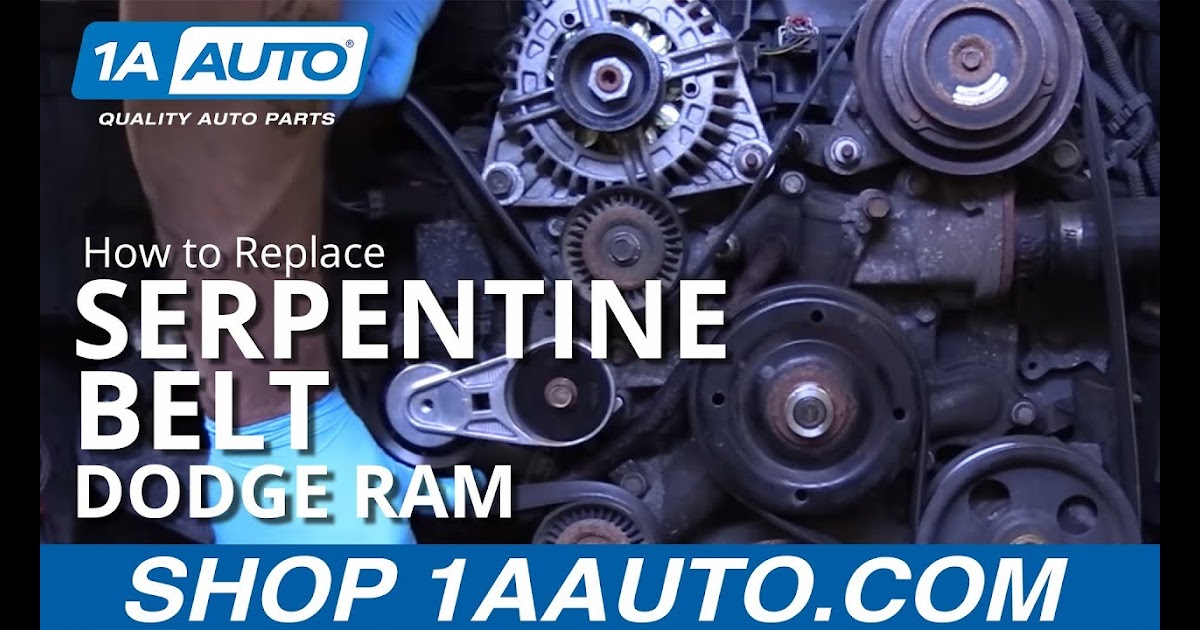

Alright, let's dive into the serpentine belt system on your 2006 Dodge Ram 1500 with the 5.7L Hemi. Understanding this system is crucial for everything from basic maintenance to diagnosing potential issues and, of course, replacing the belt itself. This guide will provide you with a detailed breakdown of the belt diagram, its components, and how it all works together. And just so you know, we have the actual diagram available for download – link will be at the end!

Purpose of the Serpentine Belt Diagram

Why bother with a diagram? Well, the serpentine belt is responsible for powering several critical engine components. If it breaks or malfunctions, you're likely stranded. A reliable diagram allows you to:

- Identify Components: Quickly locate each pulley and its function (alternator, power steering pump, etc.).

- Correct Belt Routing: Essential for replacing the belt. Incorrect routing can lead to improper operation and damage to components.

- Troubleshooting: By observing the belt's path and the components it drives, you can narrow down potential problems. For example, a squealing noise might be traced to a specific pulley.

- Maintenance: Helps you understand when to inspect and potentially replace the belt proactively, avoiding a breakdown.

Key Specs and Main Parts of the Serpentine Belt System (2006 Dodge Ram 1500 5.7L)

The serpentine belt system on the 2006 Ram 1500 5.7L consists of the following main components:

- Crankshaft Pulley (or Damper): This is the driving pulley, connected directly to the crankshaft of the engine. All power originates here. It's a large pulley, usually the lowest one in the system. The crankshaft pulley is also a harmonic balancer which helps reduce engine vibrations.

- Alternator Pulley: Powers the alternator, which charges the battery and provides electrical power to the vehicle.

- Power Steering Pump Pulley: Drives the power steering pump, providing hydraulic assistance for steering.

- Water Pump Pulley: Circulates coolant throughout the engine to maintain operating temperature.

- Air Conditioning Compressor Pulley: Engages and disengages to drive the AC compressor, providing cooled air to the cabin.

- Idler Pulley(s): These are smooth, ungrooved pulleys that guide the belt and maintain proper tension. They don't drive any specific component. Often, there are multiple idler pulleys in the system.

- Tensioner Pulley: A spring-loaded pulley that maintains the correct tension on the serpentine belt. This is critical for proper operation of all the driven components.

- Serpentine Belt: The rubber belt itself, which transmits power from the crankshaft to all other pulleys.

Specific to the 2006 Ram 1500 5.7L, the belt length is a crucial specification. While belt length varies depending on whether your truck has AC or not, you'll need to consult the proper fitment guide for your vehicle. Using the wrong length will cause tensioning issues and component damage.

Understanding the Serpentine Belt Diagram: Symbols and Conventions

Serpentine belt diagrams typically use a few standard conventions to represent the different components and belt path. Here's what to look for:

- Pulleys: Represented as circles. The center point usually indicates the pulley's axis of rotation.

- Grooved vs. Smooth Pulleys: Diagrams often distinguish between grooved pulleys (which engage the ribbed side of the belt) and smooth pulleys (which engage the smooth side of the belt).

- Belt Path: Solid or dashed lines show the path of the belt. Arrows indicate the direction of belt travel. The direction is very important, always pay attention to the arrows.

- Tensioner: Often indicated by a special symbol or labeled explicitly. The tensioner is usually drawn with an arrow indicating the direction in which to apply pressure to relieve tension during belt installation or removal.

- Component Labels: Each pulley is usually labeled with a short abbreviation indicating the component it drives (e.g., ALT for alternator, P/S for power steering, A/C for air conditioning).

While colors aren't typically standardized, some diagrams may use them to highlight specific components or belt sections. Read the diagram's key or legend carefully if colors are used.

How the Serpentine Belt System Works

The principle is simple: the engine's crankshaft drives the crankshaft pulley. This pulley, in turn, drives the serpentine belt, which wraps around all the other pulleys in the system. As the crankshaft rotates, it transmits power to each of these components through the belt.

The tensioner pulley plays a critical role in maintaining the correct belt tension. Too much tension can damage bearings in the driven components; too little tension can cause slippage, leading to reduced performance or component failure. The tensioner uses a spring mechanism to automatically adjust for belt wear and slight variations in length.

The orientation of the belt (ribbed side vs. smooth side) is also crucial. Grooved pulleys engage the ribbed side of the belt, while smooth pulleys engage the smooth (flat) side. This ensures efficient power transfer and prevents slippage.

Real-World Use: Basic Troubleshooting Tips

Here are a few common issues you might encounter and how the belt diagram can help:

- Squealing Noise: Often indicates a slipping belt. Check the belt tensioner. If the tensioner is bouncing or making noise, replace it. Also, inspect the belt for wear, cracks, or glazing. Trace the belt path to identify which pulley might be the source of the noise. Sometimes a shot bearing in an accessory like the alternator or power steering pump will cause this.

- Belt Cracks or Wear: Replace the belt immediately. The diagram helps you identify the correct routing for the new belt.

- Component Failure: If a component (e.g., alternator) fails, the belt may still be intact, but the corresponding pulley may be seized or difficult to turn. The diagram confirms which components are driven by the belt, helping you isolate the problem.

- Belt Comes Off: Likely due to a worn or damaged tensioner, a misaligned pulley, or an obstruction in the belt path. The diagram helps you check the correct routing and identify potential alignment issues. A failing pulley bearing could cause this as well.

Before replacing the belt, always make a diagram or take a picture of the belt routing. This is invaluable if you accidentally forget the correct path.

Safety Precautions

Working on the serpentine belt system can be dangerous if you're not careful. Here are a few safety tips:

- Disconnect the Battery: Always disconnect the negative battery cable before working on the system to prevent accidental starting of the engine.

- Hot Engine: Never work on the system when the engine is hot. Allow it to cool completely.

- Moving Parts: Keep your hands and tools away from the belt and pulleys when the engine is running. Serious injury can occur!

- Tensioner Tool: Use the correct tool to relieve tension on the belt tensioner. Using improper tools can damage the tensioner or cause injury.

- Belt Routing: Double-check the belt routing against the diagram before starting the engine. Incorrect routing can damage components and cause the belt to break.

The most dangerous component is the crankshaft pulley. It's directly connected to the engine and rotates at high speed. Keep your hands and tools well clear of this area.

Remember, this guide provides general information. Always refer to the specific repair manual for your 2006 Dodge Ram 1500 with the 5.7L Hemi for detailed instructions and torque specifications.

Ready to get started? Download the detailed serpentine belt diagram for your 2006 Dodge Ram 1500 5.7L Hemi HERE. This will give you a clear visual aid for troubleshooting and repairs.