2007 Mazda 6 Serpentine Belt Diagram

Alright, let's dive into the serpentine belt diagram for the 2007 Mazda 6. Whether you're planning a preemptive belt replacement, diagnosing a squealing noise, or simply expanding your automotive knowledge, understanding this diagram is crucial. This article aims to provide you with a clear and concise guide, empowering you to tackle this aspect of your Mazda 6's maintenance with confidence.

Why This Diagram Matters

The serpentine belt diagram isn't just a pretty picture; it's your roadmap for navigating the engine's accessory drive system. Its primary purposes include:

- Repair & Replacement: Accurately routing the new belt is paramount when replacing a worn or broken serpentine belt. Incorrect routing can lead to component damage or belt failure.

- Diagnosis: Understanding the belt's path helps pinpoint potential issues like misalignment or failing pulleys.

- Learning & Modification: Gaining familiarity with the system is useful for various maintenance tasks and even for planning future modifications.

Key Specs and Main Parts

The 2007 Mazda 6 came with a few engine options, each requiring a slightly different serpentine belt arrangement. The most common engines were the 2.3L inline-4 (I4) and the 3.0L V6. Make sure you consult the correct diagram for *your* specific engine. While the core principles remain the same, the pulley layout will vary.

Here's a breakdown of the key components the serpentine belt interacts with:

- Crankshaft Pulley (or Damper): This pulley is driven directly by the engine's crankshaft and serves as the primary power source for the entire serpentine belt system.

- Alternator Pulley: The alternator generates electrical power for the vehicle. The serpentine belt spins this pulley.

- Power Steering Pump Pulley: The power steering pump provides hydraulic assistance for steering.

- Air Conditioning (A/C) Compressor Pulley: The A/C compressor circulates refrigerant to cool the cabin.

- Idler Pulley(s): These pulleys provide tension and guide the belt along its path. They are smooth and often made of metal or plastic.

- Tensioner Pulley: This spring-loaded pulley maintains the correct tension on the serpentine belt. It's crucial for proper operation and belt longevity. A faulty tensioner can cause belt slippage and noise.

- Water Pump Pulley: On some engine configurations, the serpentine belt drives the water pump, which circulates coolant to regulate engine temperature.

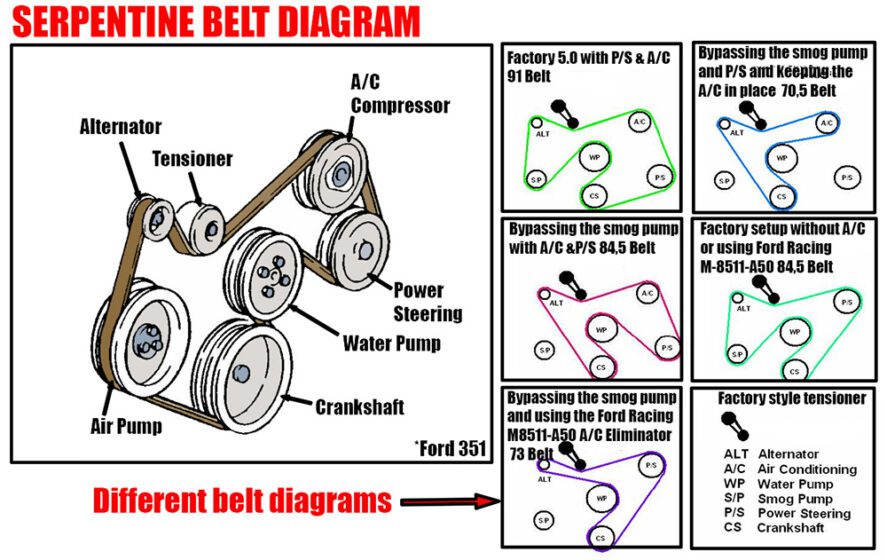

Symbols: Understanding the Diagram

Serpentine belt diagrams use standardized symbols to convey information clearly. Here's what you should know:

Lines:

- Solid Lines: Represent the path of the outer surface of the serpentine belt. This is the part that makes contact with the pulleys.

- Dotted Lines: May indicate the inner surface of the belt, showing which pulleys it wraps around from the back. These are less common but helpful for complex routing.

- Arrows: Show the direction of belt rotation around each pulley. Pay close attention to these!

Colors (Less Common): Some diagrams may use colors to distinguish between different sections of the belt or different pulley types. If present, a legend will explain their meaning.

Icons and Labels: Each pulley will be labeled with an abbreviation (e.g., ALT for alternator, P/S for power steering) or a symbol representing its function. Look for clear labels to identify each component.

Pulley Direction: Note that the pulley direction can be clockwise or counter-clockwise, depending on which side of the belt the pulley is on.

How It Works: The Serpentine Belt System

The serpentine belt system is a cleverly designed single-belt system that drives multiple engine accessories. The crankshaft pulley, directly connected to the engine, provides the rotational force. This force is then transmitted through the serpentine belt to each of the accessory pulleys.

The tensioner pulley plays a vital role by maintaining the correct amount of tension on the belt. Too little tension causes slippage, leading to reduced performance of the accessories and accelerated belt wear. Too much tension can damage the belt, pulleys, and even the accessories themselves.

The belt's routing is carefully engineered to ensure that each accessory receives the necessary power. The idler pulleys guide the belt along the optimal path, preventing it from rubbing against other components and ensuring proper contact with each driven pulley.

Real-World Use: Troubleshooting and Maintenance

Here are some common scenarios where understanding the serpentine belt diagram proves invaluable:

- Squealing Noise: A squealing noise, especially when starting the engine or using accessories like the A/C, often indicates belt slippage. Check the belt's tension and condition. A loose or worn belt will need replacement. Inspect pulleys for any damage or contamination (oil, coolant). A misaligned pulley can also cause a squeal, so use the diagram to ensure everything is correctly positioned.

- Battery Light: If the alternator isn't being driven properly due to a slipping or broken belt, the battery light may illuminate. Confirm the belt is intact and properly tensioned.

- Loss of Power Steering or A/C: A broken belt will immediately disable the accessories it drives. This is a serious issue, as it can affect your ability to steer and cool the vehicle. Replace the belt immediately.

- Belt Replacement: When replacing the belt, carefully observe the old belt's routing before removal. Take a photo or sketch the path to ensure you route the new belt correctly. Refer to the diagram for confirmation.

- Check belt for wear: Look for cracks, fraying, or missing chunks. Glazing on the belt's surface is also a sign of wear.

- Check tensioner movement: Make sure the tensioner moves smoothly through its range of motion and that the pointer falls within the acceptable range indicated on the tensioner body (if applicable).

Safety: Handling with Care

Working around the serpentine belt system involves inherent risks:

- Moving Parts: Never work on the serpentine belt system while the engine is running. The belt and pulleys are spinning at high speeds and can cause serious injury.

- Hot Components: Allow the engine to cool completely before working on the serpentine belt system. Exhaust manifolds and other components can be extremely hot and cause burns.

- Tensioner Spring: The tensioner pulley is spring-loaded and can snap back with considerable force. Use the appropriate tools to relieve tension safely during belt removal and installation. Improper handling can cause injury.

- Eye Protection: Always wear safety glasses when working on any automotive system to protect your eyes from debris.

Caution: Confirm that the engine drive belt routing diagram shown is correct for your engine and installed equipment. Always disconnect the battery before starting any work.

We have a high-resolution copy of the 2007 Mazda 6 serpentine belt diagram ready for you to download. Having a readily accessible copy will make your maintenance work much easier. Click the link below to download.

[Link to Diagram Download]