2008 Chevy Silverado 1500 5.3 Engine Wiring Harness

Alright, let's dive into the intricate world of the 2008 Chevy Silverado 1500's 5.3L engine wiring harness. This article isn't just about looking at colorful wires; it's about understanding the nervous system of your truck's powerplant. Whether you're troubleshooting a misfire, planning an engine swap, adding aftermarket accessories, or simply trying to better understand how your Silverado ticks, a solid grasp of the wiring harness is essential. We're going to break down its purpose, key components, how it functions, and how to use a wiring diagram to diagnose common issues. Plus, we'll cover important safety considerations when working with electrical systems.

Why Understand the Wiring Harness?

Think of the wiring harness as the central nervous system of your engine. It's the intricate network of wires and connectors that transmit electrical signals and power throughout the engine bay. Without it, sensors can't report data to the Engine Control Module (ECM), actuators can't perform their functions, and ultimately, your engine won't run. Understanding the wiring harness is crucial for:

- Troubleshooting Electrical Problems: Identifying shorts, opens, and corrosion.

- Performing Repairs: Replacing damaged wires, connectors, or sensors.

- Installing Aftermarket Accessories: Properly wiring in performance parts, lighting, or other modifications.

- Engine Swaps: Adapting the harness to a different engine or vehicle.

- Preventative Maintenance: Inspecting the harness for wear and tear to prevent future issues.

Key Specs and Main Parts

The 2008 Silverado 1500 5.3L engine wiring harness is a complex assembly, but it can be broken down into several key components:

- Engine Control Module (ECM) Connector(s): This is the main interface between the engine and the truck's computer. It carries signals to and from all engine sensors and actuators.

- Sensor Connectors: These connect to various sensors throughout the engine, including:

- Mass Airflow (MAF) Sensor: Measures the amount of air entering the engine.

- Throttle Position Sensor (TPS): Measures the throttle plate angle.

- Crankshaft Position Sensor (CKP): Monitors the crankshaft's position and speed.

- Camshaft Position Sensor (CMP): Monitors the camshaft's position.

- Oxygen Sensors (O2 Sensors): Measure the oxygen content in the exhaust.

- Coolant Temperature Sensor (CTS): Measures the engine coolant temperature.

- Oil Pressure Sensor: Measures the engine oil pressure.

- Actuator Connectors: These connect to various actuators that control engine functions, including:

- Fuel Injectors: Deliver fuel into the cylinders.

- Ignition Coils: Generate the spark to ignite the air-fuel mixture.

- Throttle Body Actuator (Electronic Throttle Control): Controls the throttle plate opening.

- Idle Air Control (IAC) Valve (may be present on some models): Regulates the idle speed.

- Evaporative Emission (EVAP) System Components: Controls fuel vapor emissions.

- Grounding Points: These are crucial for providing a proper electrical ground for all components. A bad ground can cause a wide range of issues.

- Power Distribution Points: These points receive power from the battery and distribute it to various components.

- Connectors: Weatherpack, Metri-Pack, and other types of connectors are used to create secure and weatherproof connections.

- Wiring: Stranded copper wire is used in various gauges (thicknesses) to carry different amounts of current.

- Protective Loom: Plastic conduit protects the wires from abrasion, heat, and other environmental factors.

Understanding Wiring Diagram Symbols

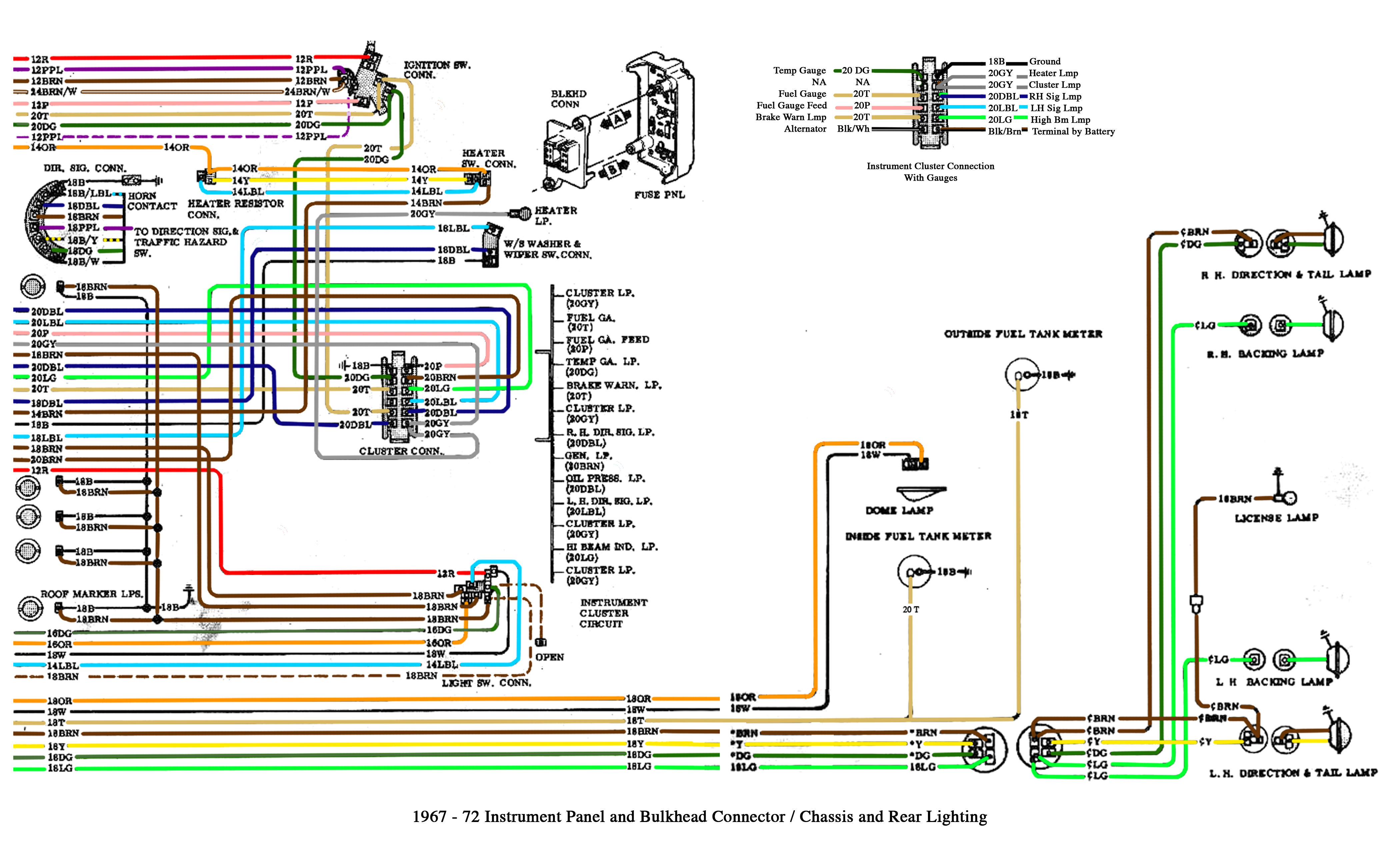

A wiring diagram is essentially a roadmap of the electrical system. To decipher it, you need to understand the symbols:

- Lines: Solid lines represent wires. Dashed lines may represent shielded wires or connections within a module.

- Colors: Each wire is color-coded (e.g., RED, BLU, GRN). The diagram will have a legend explaining the color codes. Common abbreviations include:

- RED: Red

- BLU: Blue

- GRN: Green

- BLK: Black

- WHT: White

- YEL: Yellow

- BRN: Brown

- ORG: Orange

- Connectors: Represented by various shapes, often squares or circles, with numbers or letters indicating the connector pin.

- Ground Symbols: Indicate a connection to ground.

- Component Symbols: Each component (sensor, actuator, relay, etc.) has a specific symbol. You'll need to consult the diagram's legend to identify them.

- Splices: Represented by a dot where multiple wires connect.

How It Works: A Simplified View

Let's trace a simple circuit to understand the flow of electricity. Consider the MAF sensor. The ECM provides a 5-volt reference voltage to the MAF sensor. The MAF sensor measures the airflow and generates a corresponding voltage signal back to the ECM. The ECM uses this signal to calculate the amount of fuel to inject. The wiring harness provides the pathways for these signals to travel. A break or short in this circuit will prevent the MAF sensor from communicating properly with the ECM, which will likely result in a check engine light and potentially poor engine performance.

The ECM is the brain of the engine management system. It receives inputs from numerous sensors, processes the data, and then sends outputs to various actuators to control engine parameters such as fuel injection, ignition timing, and idle speed. The wiring harness is the critical infrastructure that enables this communication.

Real-World Use: Basic Troubleshooting Tips

Here are a few basic troubleshooting tips using the wiring diagram:

- Check Engine Light (CEL): Use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs). The DTC will often point to a specific sensor or circuit. Then, consult the wiring diagram to trace the circuit and identify potential problem areas.

- Misfires: If you have a misfire code, use the wiring diagram to check the ignition coil circuits and fuel injector circuits. Look for shorts, opens, or corrosion in the wiring or connectors.

- Sensor Malfunctions: If a sensor isn't reading correctly, use the wiring diagram to check the sensor's power, ground, and signal wires. Use a multimeter to verify the voltage and continuity of each wire.

- Continuity Testing: With the circuit de-energized (key off), use a multimeter to check the continuity of wires. A broken wire will have infinite resistance (open circuit).

- Voltage Testing: With the circuit energized (key on), use a multimeter to check the voltage at various points. This can help you identify shorts or voltage drops.

Example: Let's say you have a P0102 code (MAF sensor circuit low input). Consult the wiring diagram to identify the MAF sensor's power, ground, and signal wires. Use a multimeter to check the following:

- Is the MAF sensor receiving 12V power?

- Is the MAF sensor properly grounded?

- Is the signal wire transmitting a voltage signal to the ECM?

If any of these checks fail, you've narrowed down the problem to a specific wire or connector.

Safety First!

Working with electrical systems can be dangerous. Here are some crucial safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical component. This will prevent accidental shorts and potential electrocution.

- High-Voltage Components: Be extremely careful when working near the ignition coils. They generate very high voltage that can be lethal. Ensure the ignition is off and the coils are discharged before handling them.

- Avoid Working in Wet Conditions: Water conducts electricity. Never work on electrical systems in wet or damp conditions.

- Use Proper Tools: Use insulated tools designed for electrical work.

- Consult the Service Manual: Refer to the factory service manual for specific procedures and safety precautions.

- Airbag Systems: Be extremely cautious when working near airbag system components. Accidental deployment can cause serious injury. Disconnect the battery and wait at least 10 minutes before working near the airbags.

Remember, the wiring harness is a critical component of your Silverado's engine. Understanding how it works and how to troubleshoot it can save you time and money. Be patient, methodical, and always prioritize safety.

We have the complete 2008 Chevy Silverado 1500 5.3L engine wiring diagram available for download. It will provide you with a detailed, color-coded view of the entire wiring harness, including connector pinouts and component locations. Having this resource at your fingertips will significantly aid in your troubleshooting and repair efforts.