2008 Dodge Grand Caravan Serpentine Belt Diagram

Alright, let's dive into the serpentine belt diagram for the 2008 Dodge Grand Caravan. Whether you're tackling a squealing belt, preparing for preventative maintenance, or just expanding your automotive know-how, understanding this diagram is crucial. It's not just a squiggly line picture; it's a roadmap for a vital engine system.

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram is your visual guide to how the serpentine belt is routed around the various engine accessories on your 2008 Dodge Grand Caravan. Why is this important? Several reasons:

- Belt Replacement: The most common use. When you replace the belt, you *must* route the new belt correctly. An incorrectly routed belt won't power the accessories properly and can be quickly shredded.

- Troubleshooting: Identifying which accessory is causing a problem. For example, if your power steering is failing, the diagram shows if the power steering pump is driven by the serpentine belt.

- Preventative Maintenance: Inspecting the belt path for signs of wear, misalignment, or leaks from other components (oil, coolant) that could damage the belt.

- Education: Understanding how the engine accessories are driven and interconnected. This knowledge helps you diagnose a wider range of automotive issues.

Key Specs and Main Parts of the Serpentine Belt System

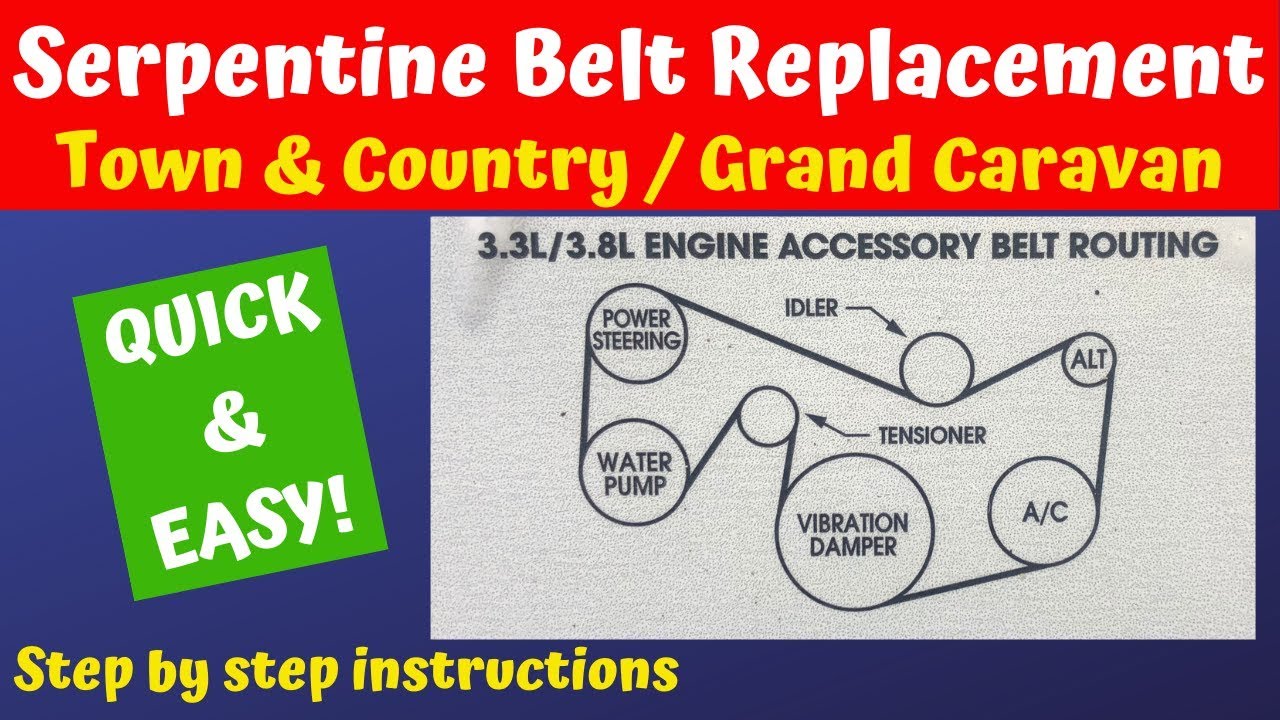

The 2008 Dodge Grand Caravan came with a few different engine options, primarily a 3.3L V6 and a 3.8L V6. The serpentine belt routing can vary slightly between these engines and, less commonly, based on whether or not you have specific options like rear air conditioning. Here's a breakdown of the key components generally found in these systems:

- Serpentine Belt: A single, continuous belt that snakes around multiple pulleys to drive various accessories. It’s typically made of a durable, reinforced rubber compound.

- Crankshaft Pulley (Harmonic Balancer): Attached to the crankshaft, this pulley is the primary driver of the serpentine belt.

- Alternator Pulley: The alternator generates electricity to power the vehicle's electrical system and charge the battery.

- Power Steering Pump Pulley: The power steering pump provides hydraulic assistance to the steering system, making it easier to turn the wheel.

- Air Conditioning Compressor Pulley: The A/C compressor circulates refrigerant in the air conditioning system.

- Water Pump Pulley: The water pump circulates coolant through the engine to regulate temperature.

- Idler Pulley(s): Smooth pulleys that guide the belt and maintain proper tension. They don't drive any accessories.

- Tensioner Pulley: A spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. This is a critical component; a failing tensioner can cause belt slippage, noise, and premature wear.

Decoding the Serpentine Belt Diagram: Symbols and Lines

Understanding the diagram involves interpreting its symbols. Here's a common key:

- Solid Lines: Represent the serpentine belt itself. The thickness of the line doesn't usually indicate anything specific, just visual clarity.

- Pulleys: Typically shown as circles. Some diagrams may label them with abbreviations like "ALT" for alternator, "P/S" for power steering, "A/C" for air conditioning, "WP" for water pump, "CRANK" for crankshaft, "IDLER" for idler pulley, and "TENSIONER."

- Arrows: Indicate the direction of rotation of each pulley. This is important for understanding which side of the belt needs to be in contact with the pulley (grooved or smooth).

- Grooved Pulleys: The diagram might slightly differentiate pulleys that require the grooved side of the belt to make contact. These are usually the driving pulleys (crankshaft, water pump, etc.).

- Smooth Pulleys: Indicate pulleys that contact the smooth (back) side of the belt. Typically, these are idler pulleys and the tensioner pulley.

- Tensioner Symbol: The tensioner pulley might have a specific symbol, often resembling a spring or an arm with an arrow indicating the direction of movement.

How the Serpentine Belt System Works

The engine's crankshaft drives the entire system. As the crankshaft rotates, the crankshaft pulley spins, which in turn drives the serpentine belt. The belt then transfers this rotational energy to all the other pulleys attached to the engine accessories (alternator, power steering pump, A/C compressor, water pump). The tensioner pulley ensures the belt remains tight against all the pulleys, preventing slippage. The idler pulleys guide the belt along the optimal path.

The serpentine belt must be routed correctly. The grooved side of the belt needs to contact the grooved pulleys, and the smooth side of the belt needs to contact the smooth pulleys. If the belt is routed incorrectly, it will likely slip, causing reduced performance of the affected accessories (e.g., weak power steering, poor A/C performance, or a discharged battery) and will likely lead to premature belt failure.

Real-World Use: Troubleshooting Tips

Here are some common issues and how the diagram can help you diagnose them:

- Squealing Noise: Often indicates a slipping belt. Check the belt tensioner to ensure it's functioning correctly. A failing tensioner won't maintain proper belt tension. Also, inspect the belt itself for glazing, cracks, or missing pieces. Trace the belt path on the diagram to check for potential leaks of oil or coolant onto the belt.

- Accessory Failure: If an accessory like the alternator isn't working, use the diagram to verify that the serpentine belt is properly routed and driving that accessory's pulley. If the belt is intact and routed correctly, the problem likely lies within the accessory itself.

- Belt Slipping Off: This could be due to a misaligned pulley, a worn belt, or a failing tensioner. Use a straight edge to check the alignment of the pulleys. Compare the belt routing to the diagram to ensure it's correct.

- Visual Inspection: Regularly inspect the belt for cracks, fraying, and missing chunks. The diagram helps you identify the entire belt path so you don't miss any sections.

Safety First: Risky Components

Working around a running engine involves risks. Here are some critical safety points:

- Never work on the serpentine belt system with the engine running unless absolutely necessary for diagnosis (e.g., pinpointing the source of a squealing noise). Even then, exercise extreme caution.

- Keep your hands, hair, and clothing clear of the moving belt and pulleys. Serious injury can result from entanglement.

- Disconnect the negative battery terminal before working on any electrical components, including the alternator.

- Be aware of hot engine components. Allow the engine to cool down before working on the serpentine belt system.

- Wear safety glasses to protect your eyes from debris.

- Use the correct tools for releasing the belt tensioner. Attempting to release the tensioner with the wrong tool can damage the tensioner or cause injury.

Remember, this article provides a general overview. Always consult your vehicle's repair manual for specific instructions and torque specifications.

We have a high-resolution, printable serpentine belt diagram for the 2008 Dodge Grand Caravan available for download. This diagram provides a clear and detailed view of the belt routing, making your repairs and maintenance easier and more accurate. Good luck!