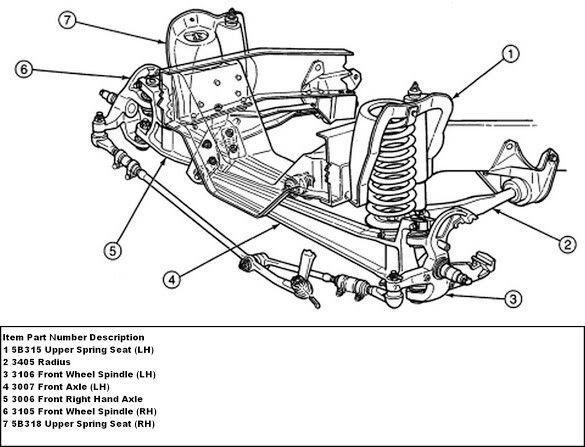

2008 Ford F250 Super Duty Front Suspension Diagram

So, you're looking to dive into the front suspension of your 2008 Ford F250 Super Duty? Excellent! Understanding the intricacies of this system is crucial, whether you're diagnosing a mysterious clunk, planning a suspension upgrade, or simply expanding your automotive knowledge. This article breaks down the front suspension diagram, arming you with the knowledge to tackle repairs and modifications with confidence. And hey, we've got the full resolution diagram ready for you to download at the end – consider it your secret weapon.

Why This Diagram Matters

A front suspension diagram isn't just a pretty picture; it's a roadmap to understanding a complex system. Here's why it's invaluable:

- Accurate Diagnosis: Forget guesswork. The diagram pinpoints component locations, helping you isolate the source of noises, vibrations, or handling issues.

- Informed Repairs: Knowing how the pieces fit together allows for correct part replacement and assembly, preventing future problems.

- Modifications & Upgrades: Planning a lift kit, upgraded shocks, or new control arms? The diagram clarifies compatibility and installation procedures.

- Preventative Maintenance: Identifying wear points allows for timely maintenance, extending the life of your suspension components.

- Learning and Understanding: Even if you don't plan on doing the work yourself, understanding the system empowers you to communicate effectively with your mechanic.

Key Specs and Main Parts of the 2008 F250 Super Duty Front Suspension

The 2008 F250 Super Duty utilizes a solid front axle suspension, a robust design built for heavy loads and challenging terrain. Key components include:

- Solid Front Axle: The heart of the system, connecting the front wheels and housing the differential. It's a rigid beam designed to withstand significant stress.

- Coil Springs: These provide the primary suspension support, absorbing bumps and maintaining ride height. The 2008 F250 uses heavy-duty coil springs to handle the truck's payload capacity.

- Shock Absorbers: Crucial for damping spring oscillations, preventing excessive bouncing and maintaining tire contact with the road. These control the rate at which the suspension compresses and rebounds.

- Radius Arms: These longitudinal arms connect the axle to the frame, controlling axle movement and preventing axle wrap (twisting under acceleration).

- Radius Arm Brackets: Weld to the frame to locate and support radius arms.

- Track Bar (Panhard Rod): This lateral bar connects the axle to the frame, preventing side-to-side movement of the axle. It centers the axle under the vehicle.

- Track Bar Bracket(s): Weld to the frame to locate and support track bar.

- Steering Linkage: Includes the steering box, pitman arm, drag link, and tie rod ends. This system translates steering wheel input into wheel movement.

- Sway Bar (Stabilizer Bar): Reduces body roll during cornering, improving stability and handling.

- Brake Calipers & Rotors: Part of the braking system but integrated into the suspension assembly.

Typical Specs to note (consult your vehicle’s specific documentation for accurate figures):

- Ride Height: Varies based on trim and options but typically around 4-6 inches from the bottom of the frame to the ground.

- Coil Spring Rate: Heavily dependent on the specific spring, but in the range of several hundred pounds per inch.

- Shock Absorber Length: Critical for proper suspension travel. Consult the manufacturer’s specifications.

Understanding the Diagram's Symbols

Suspension diagrams use standardized symbols to represent different components. Here's a basic guide:

- Solid Lines: Typically represent rigid components like the axle, radius arms, or frame.

- Dashed Lines: Often indicate hidden components or lines that run behind other parts.

- Circles: Can represent bolts, fasteners, or mounting points.

- Arrows: Show direction of movement or force.

- Color Coding (in some diagrams): Can differentiate between different systems (e.g., steering vs. suspension) or material types. However, many diagrams are black and white.

- Abbreviations: Common abbreviations include "RH" (Right Hand), "LH" (Left Hand), "FRT" (Front), "RR" (Rear), "UCA" (Upper Control Arm – not applicable on this solid axle setup), and "LCA" (Lower Control Arm – not applicable on this solid axle setup).

Always refer to the diagram's legend for specific symbol definitions. Without a legend, you can usually infer a symbol's meaning based on its context.

How the 2008 F250 Front Suspension Works

The 2008 F250's solid axle front suspension is designed for rugged durability and load-carrying capacity. Here's a simplified explanation of how it works:

- Impact Absorption: When a wheel encounters a bump, the coil spring compresses, absorbing the energy of the impact.

- Damping Oscillation: The shock absorber controls the rate at which the spring compresses and rebounds, preventing excessive bouncing and maintaining tire contact with the road.

- Axle Control: The radius arms control the fore-aft movement of the axle, preventing axle wrap under acceleration and braking.

- Lateral Stability: The track bar prevents the axle from moving side-to-side, keeping it centered under the truck.

- Steering Input: The steering box translates the driver's steering wheel input into linear motion. The pitman arm then transfers this motion to the drag link, which connects to the steering knuckle on the axle. This movement pivots the wheels for steering.

- Body Roll Reduction: The sway bar connects the two sides of the suspension, resisting body roll during cornering and improving stability.

Real-World Use: Basic Troubleshooting Tips

Here's how you can use the diagram to troubleshoot common suspension problems:

- Clunking Noise: Possible causes include worn-out ball joints, loose sway bar links, or worn shock absorber bushings. The diagram helps you locate these components for inspection.

- Wandering Steering: Could be due to worn tie rod ends, a loose track bar, or worn ball joints. The diagram identifies the steering linkage components for inspection.

- Excessive Bouncing: Indicates worn-out shock absorbers. The diagram shows the location of the shocks for easy replacement.

- Uneven Tire Wear: Can be caused by misaligned suspension components, such as a bent radius arm or a worn ball joint. A visual inspection using the diagram as a guide can help identify the damaged component.

- Squeaking Noise: Could be caused by dry bushings in the radius arms or sway bar links. Identify the potential locations and apply lubricant.

Important: Always perform a thorough visual inspection before attempting any repairs. And if you're unsure about any procedure, consult a qualified mechanic.

Safety First: Risky Components

Working on suspension systems can be dangerous due to the stored energy in the springs and the potential for heavy components to fall. Here are some crucial safety precautions:

- Spring Compression: Never attempt to disassemble a strut or coil spring assembly without using a proper spring compressor. These tools are designed to safely contain the spring's energy. Incorrect spring compression can cause serious injury or death.

- Vehicle Support: Always use jack stands to support the vehicle when working underneath it. Never rely solely on a jack.

- Torque Specifications: Always tighten bolts and nuts to the manufacturer's specified torque values. Overtightening can damage components, while undertightening can lead to failure.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Disconnect Battery: To prevent accidental electrical shorts or airbag deployment, disconnect the negative battery cable before starting any work.

- Brake Lines: Be extremely careful when working near brake lines. Damage to a brake line can result in complete brake failure.

When in doubt, seek professional assistance. Your safety is paramount.

Ready to Download the Diagram?

Now that you've got a solid understanding of the 2008 Ford F250 Super Duty front suspension, you're ready to put your knowledge to use! Click HERE to download the high-resolution diagram. Use it wisely, stay safe, and happy wrenching!