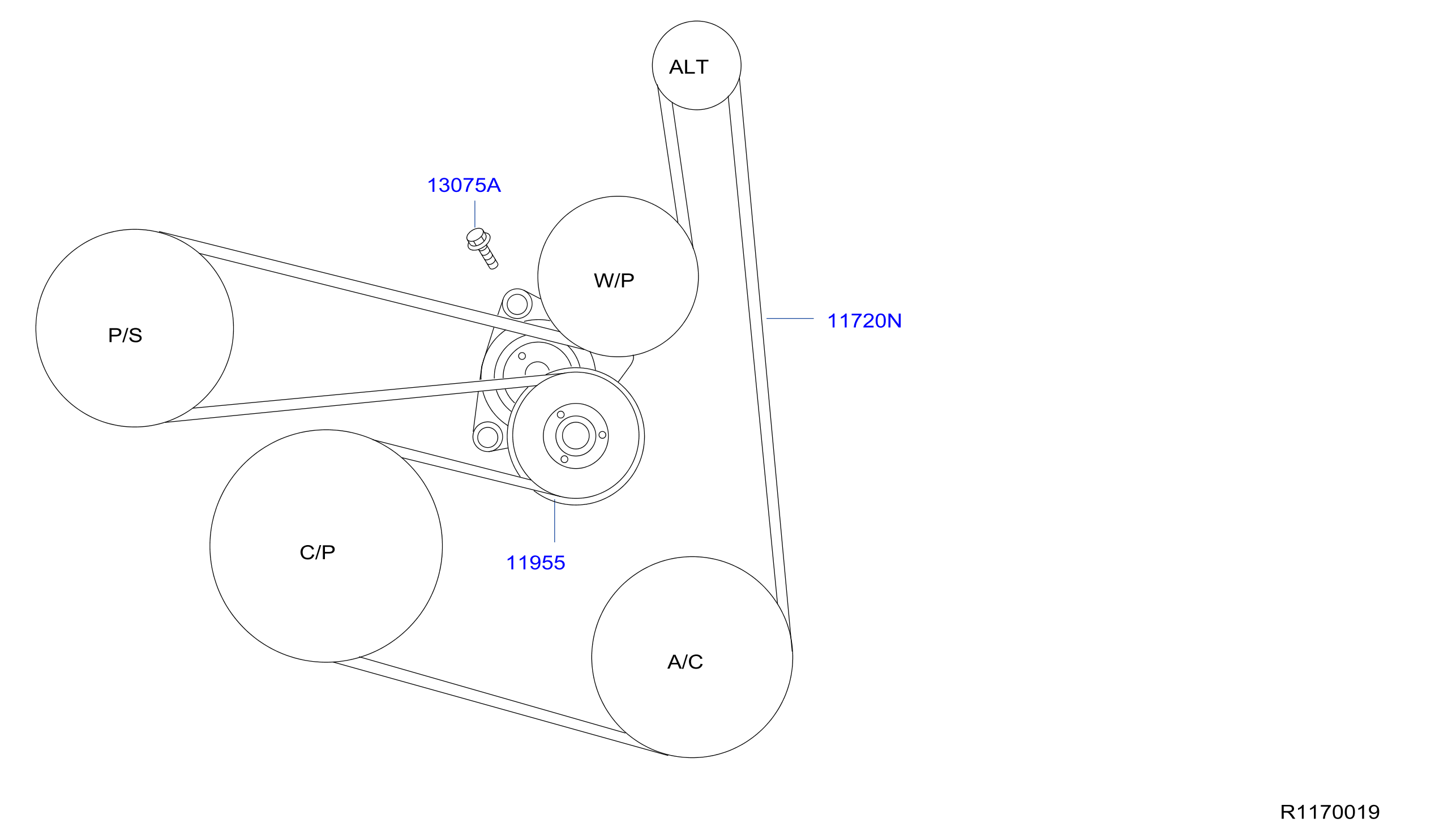

2008 Nissan Sentra Serpentine Belt Diagram

The serpentine belt, also known as the accessory drive belt, is a critical component in your 2008 Nissan Sentra. It's responsible for powering several vital systems, from the alternator that charges your battery to the power steering pump that makes turning the wheel easier, and the air conditioning compressor that keeps you cool in the summer. Understanding its routing is essential for maintenance, repairs, and even certain performance modifications. This guide provides a detailed explanation of the 2008 Nissan Sentra serpentine belt diagram, covering its purpose, key components, how it works, and practical troubleshooting tips.

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram serves several important purposes:

- Repair and Replacement: The most common use is for replacing a worn or broken serpentine belt. The diagram ensures you route the new belt correctly. Incorrect routing can lead to component damage and system failure.

- Troubleshooting: When diagnosing issues like a dead battery, loss of power steering, or a malfunctioning AC, the diagram helps you visually inspect the belt's condition and tension.

- Preventative Maintenance: Regularly checking the belt's condition, guided by the diagram, allows you to identify potential problems early, preventing costly breakdowns.

- Learning and Understanding: For DIY mechanics, understanding the belt's path is fundamental to grasping how the engine's accessory systems function.

Key Specs and Main Parts of the Serpentine Belt System

The 2008 Nissan Sentra utilizes a single serpentine belt to drive multiple accessories. The exact length of the belt can vary slightly depending on whether the vehicle has AC. It’s essential to use the correct belt specified for your model. Refer to your owner's manual or a reputable parts supplier for the correct part number.

The key components included in the serpentine belt system are:

- Crankshaft Pulley: This is the driving force behind the entire system, connected directly to the engine's crankshaft. Its rotation powers the belt.

- Alternator Pulley: The alternator generates electricity to charge the battery and power the vehicle's electrical system. The serpentine belt spins this pulley.

- Power Steering Pump Pulley: The power steering pump provides hydraulic assistance for steering. The belt drives this pulley.

- Air Conditioning Compressor Pulley: The AC compressor is responsible for cooling the air circulating through the cabin. The belt spins its pulley.

- Tensioner Pulley: The tensioner pulley maintains the proper tension on the serpentine belt. It's spring-loaded and typically self-adjusting. The automatic tensioner applies consistent force, preventing slippage and premature wear.

- Idler Pulley(s): Some Sentra models may have one or more idler pulleys. These pulleys simply provide a smooth path for the belt to travel around other components and maintain the correct wrap angle on the driven pulleys. They do not drive any specific accessory.

Symbols and Conventions in the Diagram

Serpentine belt diagrams typically use standard conventions to represent components and the belt's path. Understanding these symbols is crucial for interpreting the diagram correctly:

- Solid Lines: The solid line indicates the front side of the belt. This is the side that comes into direct contact with the pulleys' grooved surfaces.

- Dotted Lines: A dotted line typically represents the back side of the belt. This side makes contact with smooth pulleys like the idler and tensioner.

- Arrows: Arrows indicate the direction of belt travel. Follow these arrows to understand how the belt wraps around each pulley.

- Pulley Symbols: Pulleys are usually represented by circles. Larger circles may indicate larger pulleys, like the crankshaft pulley.

- Component Labels: Each pulley will be labeled with its corresponding component, such as "ALT" for alternator, "P/S" for power steering, "A/C" for air conditioning compressor, and "CRANK" for crankshaft.

- Tensioner Location: The tensioner pulley will be clearly identified, often with a label like "TENSIONER" or simply "TENS".

How the Serpentine Belt System Works

The serpentine belt system is a relatively simple, yet critical, power transmission system. The engine's crankshaft drives the crankshaft pulley. This, in turn, spins the serpentine belt, which is routed around all the other accessory pulleys. The friction between the belt and the pulleys causes them to rotate, powering the respective accessories. The tensioner pulley maintains the correct amount of tension on the belt, ensuring adequate grip and preventing slippage. Without proper tension, the belt may slip, leading to reduced or no power to the accessories, potentially causing issues like a dead battery, hard steering, or lack of AC.

The serpentine belt’s efficiency relies heavily on consistent contact between the belt grooves and the pulley grooves. A worn or cracked belt will not make consistent contact, and this will likely result in slipping, squealing, and a decrease in accessory performance. This is why regular inspection and timely replacement is important.

Real-World Use: Basic Troubleshooting Tips

Here are some common issues and how the serpentine belt diagram can help in troubleshooting:

- Squealing Noise: A squealing noise, especially when starting the engine or turning the steering wheel, often indicates a loose or worn serpentine belt. Use the diagram to inspect the belt for cracks, fraying, or glazing. Also, check the tensioner pulley for proper operation. It should move smoothly and maintain adequate tension.

- Dead Battery: If the alternator isn't charging the battery, the serpentine belt could be the culprit. Use the diagram to verify that the belt is properly routed around the alternator pulley and that the belt is not slipping.

- Loss of Power Steering: If the steering becomes difficult, the power steering pump may not be receiving power. Check the belt routing to ensure it's properly engaged with the power steering pump pulley.

- AC Malfunction: If the AC isn't cooling properly, the AC compressor might not be operating. Verify the belt routing and tension to ensure the AC compressor pulley is being driven correctly.

- Belt Slippage: Visible signs of belt slippage, such as rubber dust or debris around the pulleys, indicate a worn or loose belt. Replace the belt and inspect the tensioner pulley.

Safety Considerations

Working on the serpentine belt system can be hazardous. Always disconnect the negative battery terminal before working on the engine. This prevents accidental starts, which could cause serious injury. The cooling fan is a particular hazard; even with the engine off, it can cycle on unexpectedly if the ignition is switched on. Keep your hands clear of the fan blades at all times.

The tensioner pulley also contains a powerful spring. Use the correct tools to release the tension on the belt. Never attempt to release the tensioner with makeshift tools, as this could result in injury.

Finally, remember that the engine can be hot, especially after running. Allow the engine to cool completely before working on the serpentine belt system. Failure to do so could result in burns.

Before proceeding, make sure the car is safely supported using jack stands. Never rely solely on a jack.

We understand the importance of having the right resources for DIY projects. We have the 2008 Nissan Sentra Serpentine Belt Diagram file available for you to download. This will provide you with a clear and detailed visual aid for your maintenance and repair tasks.