2010 Chrysler Town And Country Serpentine Belt Diagram

For the seasoned DIYer or experienced mechanic, maintaining a vehicle often involves familiarizing oneself with its inner workings. The serpentine belt system is a critical component of the 2010 Chrysler Town and Country, driving several essential accessories. Understanding its routing via a diagram is invaluable for repairs, preventative maintenance, and even general learning about automotive systems. This article delves into the 2010 Chrysler Town and Country serpentine belt diagram, providing you with the knowledge to confidently tackle related tasks.

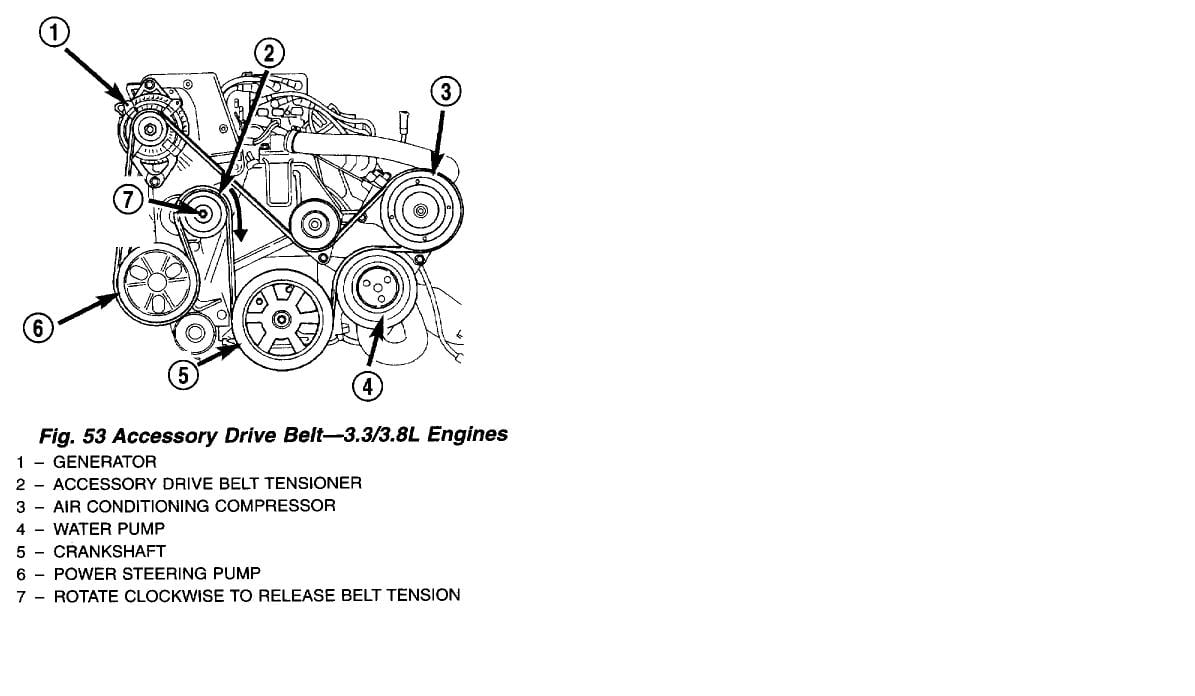

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram serves as a visual guide showing the precise path the serpentine belt takes around the various pulleys of your 2010 Chrysler Town and Country's engine. Why is this important? Consider these scenarios:

- Belt Replacement: After years of use and exposure to heat, the serpentine belt will eventually wear out, crack, or fray. The diagram ensures you route the new belt correctly, avoiding damage to accessories or premature belt failure.

- Accessory Replacement: When replacing the alternator, power steering pump, A/C compressor, or idler pulley, you must remove and reinstall the serpentine belt. The diagram is crucial for accurate reassembly.

- Troubleshooting: A squealing or chirping noise could indicate a worn belt, a misaligned pulley, or a failing accessory. Using the diagram helps you identify the potential source of the problem and inspect the relevant components.

- Learning: Understanding the belt's path gives you a broader understanding of how the engine accessories are powered and interconnected.

Key Specs and Main Parts

The 2010 Chrysler Town and Country typically uses a single serpentine belt to drive multiple accessories. The specific belt length can vary slightly depending on the engine configuration (3.8L V6 or 4.0L V6), so always verify the correct part number for your vehicle using the VIN. Key components of the serpentine belt system include:

- Crankshaft Pulley: The main driving pulley, connected directly to the engine's crankshaft. It's usually the largest pulley in the system.

- Alternator Pulley: Powers the electrical system and charges the battery.

- Power Steering Pump Pulley: Provides hydraulic assistance for steering.

- A/C Compressor Pulley: Drives the air conditioning compressor.

- Idler Pulley(s): Smooth, non-driven pulleys used to guide the belt and maintain proper tension and wrap angle around other pulleys.

- Tensioner Pulley: Spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. This is crucial for optimal accessory performance and belt life.

Understanding the Diagram's Symbols

Serpentine belt diagrams are typically presented as simplified schematics. Here's how to interpret common symbols:

- Solid Lines: Represent the serpentine belt itself. The thickness of the line doesn't usually indicate anything specific, but it clearly shows the belt's path.

- Circles or Disks: Represent the various pulleys. Often, these circles will have labels indicating the accessory they drive (e.g., "ALT" for alternator, "P/S" for power steering).

- Arrows: Indicate the direction of rotation for each pulley. This is critical for ensuring the belt is routed correctly. Pay close attention to which side of the belt (ribbed or smooth) contacts each pulley.

- Tensioner Symbol: Usually depicted as a spring-loaded arm or a pulley with an arrow indicating the direction of movement during belt installation or removal. Some diagrams may also include the torque specification for the tensioner bolt.

- Color Coding: While not always present, some diagrams use color coding to highlight specific sections of the belt path or to distinguish between different types of pulleys. Refer to the legend on the diagram if colors are used.

- Icons or Abbreviations: Standard automotive abbreviations such as ALT (alternator), P/S (power steering), A/C (air conditioning), CRK (crankshaft), and IDL (idler) are commonly used.

How the Serpentine Belt System Works

The serpentine belt system operates on the principle of rotational motion transfer. The engine's crankshaft drives the crankshaft pulley, which, in turn, drives the serpentine belt. The belt then wraps around the pulleys of the various engine accessories (alternator, power steering pump, A/C compressor), transferring rotational energy to them. The tensioner pulley ensures the belt maintains adequate grip on all pulleys by applying consistent tension. Proper tension is critical; too loose, and the belt will slip, causing accessories to malfunction. Too tight, and it can lead to premature bearing wear in the accessories or even belt failure.

Real-World Use: Basic Troubleshooting Tips

Using the serpentine belt diagram, you can perform basic troubleshooting:

- Belt Squeal: A squealing noise, especially upon starting or during acceleration, often indicates a loose or worn belt. Inspect the belt for cracks, fraying, or glazing. Check the tensioner to ensure it's functioning correctly. Use the diagram to verify the belt is properly routed and seated in all pulley grooves.

- Accessory Malfunction: If an accessory (e.g., power steering, A/C) is not functioning correctly, consult the diagram to verify the belt is properly routed and driving that accessory's pulley. A slipping belt can prevent an accessory from operating at full capacity.

- Visual Inspection: Use the diagram to quickly verify the belt's routing after any maintenance work. Ensure the belt is not rubbing against any brackets, hoses, or other components.

- Belt Installation: When installing a new belt, carefully follow the diagram's routing. Use a serpentine belt tool (or a suitable wrench) to relieve tension on the tensioner pulley, allowing you to easily install the belt. Once the belt is routed, slowly release the tensioner to engage the belt. Double-check the routing one last time before starting the engine.

Safety Considerations

Working around a serpentine belt system can be hazardous if proper precautions are not taken:

- Engine Off: Always ensure the engine is completely off and the ignition key is removed before working on the serpentine belt system. Accidental engine starting can cause serious injury.

- Cool Engine: Allow the engine to cool down completely before touching any components. Exhaust manifolds and other engine parts can be extremely hot.

- Moving Parts: Keep your hands, hair, and clothing away from the serpentine belt and pulleys while the engine is running. These are extremely dangerous moving parts.

- Battery Disconnect: Disconnecting the negative battery terminal provides an extra layer of safety by preventing accidental starting of the engine during repairs.

- Proper Tools: Use the correct tools for the job, especially when dealing with the tensioner pulley. Incorrect tools can damage the tensioner or cause injury.

The 2010 Chrysler Town and Country serpentine belt diagram is an invaluable resource for maintaining and repairing your vehicle. By understanding the diagram's symbols, the system's operation, and the associated safety precautions, you can confidently tackle serpentine belt-related tasks.

We have the 2010 Chrysler Town and Country Serpentine Belt Diagram file available for you. You can download it from [insert link here].