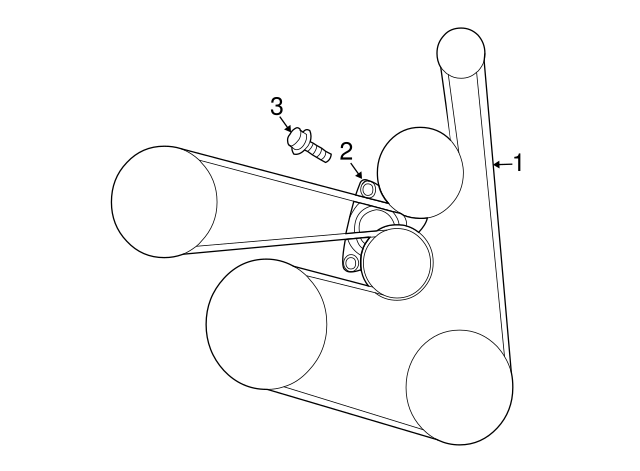

2010 Nissan Altima 2.5 Belt Diagram

Alright folks, let's dive into the serpentine belt system on the 2010 Nissan Altima with the 2.5L engine. Understanding this system is crucial for several reasons: from preventative maintenance and diagnosing annoying squeals to tackling full-blown belt replacements and accessory component repairs. This isn't just a rubber band; it's the lifeline of several vital systems in your Altima.

Purpose of the Serpentine Belt Diagram

Why bother with a diagram? Well, imagine trying to re-string a complex musical instrument without knowing where each string goes. That's essentially what you're doing if you attempt to work on the serpentine belt without a clear understanding of its routing. The diagram serves as your roadmap, ensuring correct belt installation, proper tension, and ultimately, reliable operation of your Altima's accessories. It’s also incredibly useful for verifying that all components are aligned correctly if you're chasing down vibration issues or unusual wear patterns. Whether you are an experienced DIYer or just want to understand your car better, knowing where the belt goes is critical.

Key Specs and Main Parts

The 2010 Altima 2.5L uses a single serpentine belt to drive multiple components. Let's break down the key players:

- Crankshaft Pulley (or Damper): This is the heart of the system, driven directly by the engine. It’s the starting point for the belt's journey.

- Alternator: The alternator generates electricity to keep your battery charged and power the electrical components in your car. A failing belt can lead to a dead battery.

- Power Steering Pump: This pump provides hydraulic pressure to assist with steering. A slipping belt here can result in stiff or difficult steering.

- Air Conditioning Compressor: This compressor is responsible for cooling the cabin. Belt failure leads to no A/C.

- Idler Pulley(s): These smooth, non-driven pulleys guide the belt and maintain its proper routing. They often contribute to noise issues when their bearings fail.

- Tensioner Pulley: This spring-loaded pulley maintains the correct tension on the belt. A faulty tensioner can cause belt slippage, noise, and premature belt wear. This is a critical component.

Understanding the Symbols on the Diagram

Serpentine belt diagrams aren't exactly works of art, but they use standardized symbols to convey important information. Here’s a breakdown:

- Solid Lines: Represent the belt itself, showing its path around the various pulleys. The thickness of the line sometimes indicates the belt width, but this isn’t always consistent.

- Arrows: Indicate the direction of rotation for each pulley. This is extremely important for correct belt routing. Double-check these!

- Component Symbols: Each component (alternator, power steering pump, etc.) is represented by a stylized symbol, often a circle with a brief label (e.g., "ALT," "P/S").

- Tensioner Symbol: Usually depicted as a spring-loaded arm or a pulley with a spring symbol, indicating its function in maintaining belt tension.

- Dashed Lines: May indicate the *back* of the belt making contact with a pulley, differentiating it from the grooved side. This helps visualize the belt's path in 3D.

Color is rarely used in these diagrams. However, if you find a colorized diagram, it might be highlighting a specific section of the belt or component for emphasis.

How the Serpentine Belt System Works

The serpentine belt system is a marvel of efficiency. The engine's crankshaft rotates, driving the crankshaft pulley. The serpentine belt, wrapped around this pulley, transfers this rotational force to all the other accessory pulleys. Each pulley drives its respective component (alternator, power steering pump, etc.).

The tensioner pulley plays a vital role. It maintains constant pressure on the belt, preventing slippage. Without proper tension, the belt won't grip the pulleys effectively, leading to reduced performance or complete failure of the accessories.

Think of it like a well-choreographed dance. Each component relies on the others to function correctly. A problem with one component can affect the entire system.

Real-World Use: Basic Troubleshooting

Okay, so you have the diagram. How do you use it in the real world? Here are a few basic troubleshooting tips:

- Squealing Noise: A common symptom is a high-pitched squealing noise, especially when the engine is first started or under load (e.g., turning the steering wheel at low speeds). This often indicates a loose or worn belt, a failing tensioner, or a glazed pulley. Use the diagram to visually inspect the belt for cracks, fraying, or missing chunks. Also, check the tensioner for smooth operation. If it's bouncing around excessively, it's likely failing.

- Accessory Malfunction: If your alternator isn't charging the battery, your power steering is stiff, or your A/C isn't blowing cold, the serpentine belt is a prime suspect. The diagram will help you quickly identify which components are driven by the belt.

- Belt Slippage: Look for signs of belt dust or debris around the pulleys. This indicates that the belt is slipping, even if you don't hear a squeal. Slippage can be caused by a worn belt, a faulty tensioner, or a seized component.

- Installation Errors: If you've recently replaced the belt, double-check the routing using the diagram. It's surprisingly easy to misroute the belt, leading to immediate failure.

Safety Considerations

Working on the serpentine belt system can be dangerous if you're not careful. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components, including the alternator. This prevents accidental shocks and damage to the electrical system.

- Hot Engine: Never work on the serpentine belt system when the engine is hot. Allow the engine to cool completely before touching any components.

- Moving Parts: The serpentine belt system contains numerous moving parts. Keep your hands, hair, and clothing clear of the belt and pulleys when the engine is running. Seriously, this is critical.

- Tensioner Spring: The tensioner pulley is spring-loaded and can snap back with considerable force. Use the correct tools to relieve the tension and prevent injury.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

Conclusion

The serpentine belt system is a vital part of your 2010 Nissan Altima 2.5L. Understanding its components and how they work together is essential for proper maintenance and troubleshooting. By using the belt diagram, you can confidently diagnose issues, replace the belt, and keep your Altima running smoothly. This isn’t just about saving money; it’s about understanding your car and taking ownership of its maintenance.

We have the full, high-resolution diagram available for download. It includes all the necessary details for accurate belt routing and component identification. Feel free to download it, print it out, and keep it handy in your garage. It's a valuable resource for any Altima owner.