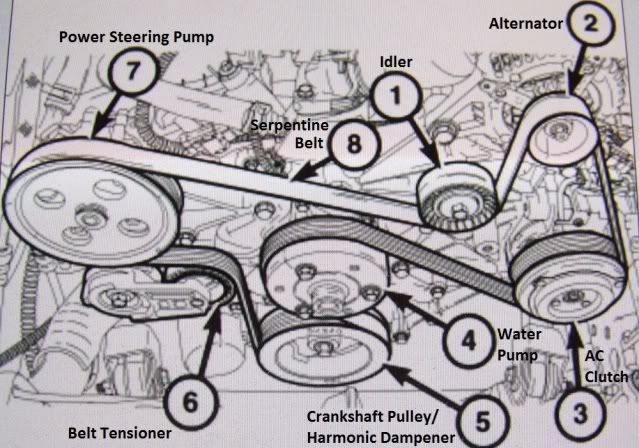

2011 Jeep Grand Cherokee 3.6 Serpentine Belt Diagram

Alright, let's dive into the serpentine belt system on the 2011 Jeep Grand Cherokee with the 3.6L Pentastar V6 engine. This article will serve as your comprehensive guide to understanding the serpentine belt diagram, covering its purpose, components, operation, and practical troubleshooting tips. This is crucial knowledge whether you’re replacing the belt, diagnosing squealing noises, or simply wanting to better understand your vehicle's engine.

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram is essentially a roadmap for your engine's accessory drive system. It illustrates the path the serpentine belt takes as it weaves around various pulleys, powering essential components. Knowing the belt's routing is absolutely critical for:

- Proper Installation: Installing the belt incorrectly can lead to immediate failure of the system, damage to components, and leaving you stranded.

- Troubleshooting: Identifying the affected component based on belt slippage, noise, or visual inspection becomes much easier with the diagram.

- Component Replacement: When replacing components like the alternator or power steering pump, you'll need to remove and reinstall the belt, referencing the diagram ensures proper routing.

- General Understanding: Having a better grasp of how your engine operates empowers you to perform preventative maintenance and potentially avoid costly repairs down the line.

Key Specs and Main Parts

The 2011 Jeep Grand Cherokee 3.6L uses a single serpentine belt to drive several critical engine accessories. Here are the key components you'll find in the system:

- Crankshaft Pulley (Harmonic Balancer): The heart of the system, driven directly by the engine. This is where the power originates to drive all other accessories.

- Alternator: Generates electrical power to recharge the battery and run electrical components.

- Power Steering Pump: Provides hydraulic pressure to assist in steering.

- Air Conditioning Compressor: Compresses refrigerant to cool the vehicle's cabin.

- Water Pump: Circulates coolant through the engine and radiator to regulate temperature.

- Tensioner Pulley: Maintains constant tension on the serpentine belt, preventing slippage. The tensioner uses a spring-loaded mechanism to automatically adjust for belt wear and stretch.

- Idler Pulley(s): Smooth, bearing-mounted pulleys that guide the belt and optimize its wrap angle around other components.

The belt itself is typically made of EPDM (Ethylene Propylene Diene Monomer) rubber, which provides excellent heat and abrasion resistance. The belt may have a part number that you can use to order a replacement. For the 2011 Grand Cherokee 3.6L, a common replacement belt is around 90 inches in length but always verify the correct part number for your specific vehicle trim and options.

Symbols and Diagram Conventions

Serpentine belt diagrams typically employ a consistent set of symbols to represent the various components. Understanding these symbols will make interpreting the diagram much easier.

- Solid Lines: These represent the path of the serpentine belt itself. Follow the line to trace the belt's routing around the various pulleys.

- Circles: Represent pulleys. The size of the circle doesn't necessarily correspond to the actual size of the pulley.

- Labeled Pulleys: Each pulley will be labeled with an abbreviation indicating its function (e.g., ALT for alternator, P/S for power steering, A/C for air conditioning, W/P for water pump, CRANK for crankshaft).

- Direction Arrows: Small arrows indicate the direction of rotation for each pulley. This is helpful in understanding how the belt drives each component.

- Tensioner Symbol: Usually depicted as a pulley with a spring symbol next to it, indicating its spring-loaded tensioning mechanism.

- Grooved vs. Smooth Pulleys: Some diagrams may differentiate between grooved pulleys (which drive accessories) and smooth idler pulleys.

While colors aren't typically used in most printed diagrams, online versions might use color coding to highlight different sections of the belt path for clarity.

How It Works

The serpentine belt system is a relatively simple, yet crucial, component of your engine. The crankshaft pulley, driven by the engine's rotation, is the primary power source. The serpentine belt wraps around this pulley and transfers rotational energy to all the other accessory pulleys.

The tensioner pulley plays a critical role in maintaining the correct belt tension. As the belt ages, it stretches. The tensioner automatically adjusts, maintaining consistent pressure on the belt to prevent slippage. A failing tensioner will often cause belt squealing, especially during cold starts or under heavy load.

The order in which the belt wraps around the pulleys is carefully designed to ensure optimal performance and prevent belt slippage. The diagram shows that belt wrap, to get the most efficient routing. This also takes into account direction of rotation for each driven component.

Real-World Use and Basic Troubleshooting

Here are some common serpentine belt-related problems and how the diagram can help with troubleshooting:

- Squealing Noise: Often indicates a worn, glazed, or loose belt. Check the belt for cracks, fraying, or signs of glazing (a shiny, hard surface). Use the diagram to ensure the belt is properly routed and that the tensioner is functioning correctly. A worn tensioner can also cause squealing.

- Belt Slippage: Can be caused by a worn belt, a faulty tensioner, or a seized accessory. Inspect the belt and tensioner. Try turning each accessory pulley by hand with the engine off. If one is difficult to turn, it may be seized.

- Cracked or Frayed Belt: Indicates wear and tear. Replace the belt immediately, and investigate the cause of the wear. Misalignment of pulleys or a faulty tensioner can accelerate belt wear.

- Accessory Malfunction: If an accessory (e.g., alternator, power steering pump) stops working, check the serpentine belt first. A broken or slipped belt is a common cause.

When troubleshooting, always start by visually inspecting the belt and all pulleys. Pay close attention to the tensioner. It should move smoothly and maintain consistent tension on the belt. If the tensioner is bouncing excessively or making noise, it needs to be replaced.

Safety Precautions

Working on the serpentine belt system can be dangerous if you don't take proper precautions. Here are some key safety considerations:

- Disconnect the Battery: Before working on any electrical components, disconnect the negative battery terminal to prevent accidental shorts or electrical shocks.

- Engine Off and Cool: Never work on the serpentine belt system with the engine running or hot. Wait for the engine to cool down completely.

- Keep Hands and Clothing Clear: The serpentine belt can cause serious injury if it catches your hands or clothing. Keep your hands and clothing clear of the belt and pulleys when the engine is running.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Belt Tensioner: Be extremely careful when releasing the belt tension. The tensioner is spring-loaded and can snap back forcefully. Use the correct tool to safely release the tension. Refer to your vehicle's repair manual for the proper procedure.

- Beware of Hot Surfaces: Engine components can be very hot, even after the engine has been turned off for a while. Wear gloves to protect your hands from burns.

The serpentine belt system contains rotating parts that can cause serious injury. Always exercise caution and follow proper safety procedures when working on this system.

Remember, if you're unsure about any aspect of the repair, consult a qualified mechanic. It's better to be safe than sorry.

We have a detailed serpentine belt diagram file specifically for the 2011 Jeep Grand Cherokee 3.6L. You can download it here (link to file download).