2012 Chrysler 200 2.4 Liter Serpentine Belt Diagram

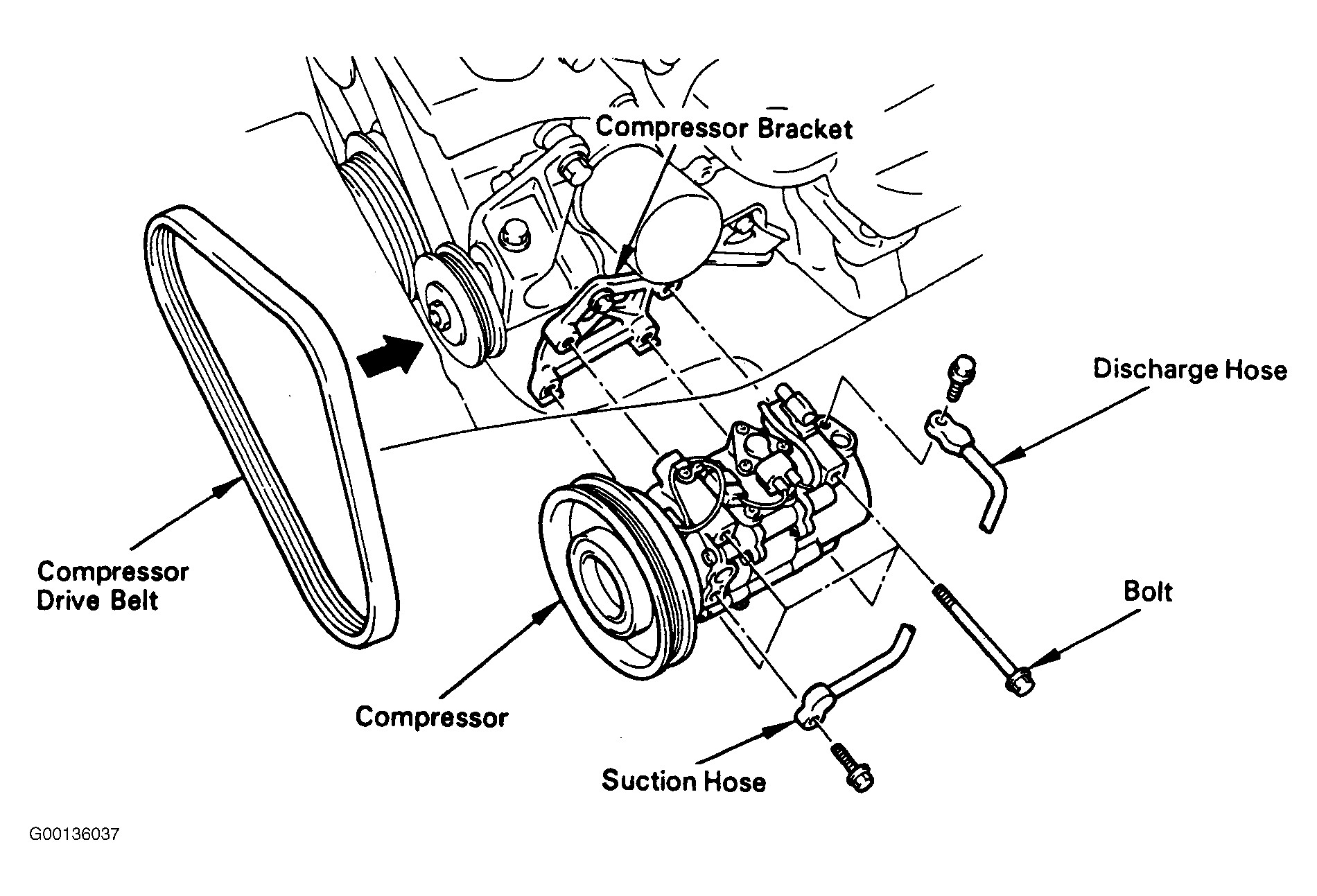

Alright, let's dive into the serpentine belt system for the 2012 Chrysler 200 with the 2.4-liter engine. This is a bread-and-butter maintenance item, and understanding its layout can save you a lot of time, money, and frustration. This article will act as a comprehensive guide to interpreting the serpentine belt diagram specific to this vehicle. We've got the diagram itself on file, which you can download to follow along. Consider this your visual aid for serpentine belt mastery.

Purpose of Understanding the Serpentine Belt Diagram

Why bother learning this? Well, several reasons. The serpentine belt drives essential engine components. If it breaks, you're stranded. Knowing the diagram helps you:

- Perform Routine Maintenance: Inspect the belt for wear and tear.

- Troubleshoot Problems: Is that squealing noise the belt? Is an accessory not working? The diagram helps isolate the issue.

- Replace the Belt: Crucial for preventing breakdowns and maintaining optimal vehicle performance.

- Identify Components: Quickly locate accessories like the power steering pump, alternator, and AC compressor.

- Learn Engine Layout: Gain a better understanding of how your engine functions.

- Verify Proper Routing: Ensuring you've routed a new belt correctly is vital to avoid damage.

Key Specs and Main Parts of the 2012 Chrysler 200 2.4L Serpentine Belt System

The 2012 Chrysler 200 2.4L uses a single, multi-ribbed serpentine belt to drive various engine accessories. Here’s a breakdown of the key components:

Essential Components:

- Crankshaft Pulley (or Damper): The driving force behind the entire system. Connected directly to the engine's crankshaft.

- Alternator Pulley: Powers the electrical system, charging the battery and providing power to accessories.

- Power Steering Pump Pulley: Provides hydraulic power for steering assistance.

- Air Conditioning (A/C) Compressor Pulley: Circulates refrigerant for cooling the cabin.

- Idler Pulley(s): Smooth, unpowered pulleys that guide the belt and maintain proper tension and wrap angle around other pulleys. Wrap angle is crucial for efficient power transfer; it is the amount of contact the belt has with the pulley.

- Tensioner Pulley: Spring-loaded pulley that maintains constant tension on the belt, preventing slippage. This is *critical* for proper operation. The tensioner often includes an indicator mark showing the ideal range of motion.

- Water Pump Pulley: Circulates coolant through the engine to prevent overheating.

Key Specifications:

- Belt Length: The exact length will depend on the specific manufacturer, but it will be close to the OEM spec. Always use a belt designed *specifically* for this vehicle and engine. Refer to the vehicle's service manual.

- Rib Count: The number of longitudinal ribs on the belt. It needs to match the pulleys it interfaces with (usually 6 ribs).

- Material: Typically made of EPDM rubber (ethylene propylene diene monomer), known for its durability and resistance to heat and oil.

Understanding Symbols in the Serpentine Belt Diagram

A serpentine belt diagram isn't just a picture; it's a technical drawing with standardized symbols. Here's what to look for:

- Solid Lines: Represent the path of the serpentine belt. The thickness of the line usually doesn't indicate anything specific.

- Arrows: Indicate the direction of belt rotation. Note that each pulley turns in the opposite direction of the pulley the belt is coming *from*.

- Component Icons: Simplified drawings of each pulley, often labeled with abbreviations like "ALT" for alternator, "P/S" for power steering, "A/C" for air conditioning, etc. These icons are designed to be easily recognizable.

- Tensioner Symbol: Usually a pulley symbol with an adjacent arrow indicating the direction the tensioner arm moves to release tension. This is *essential* for removing and installing the belt.

- Pulley Diameters: Sometimes the diagram includes the diameter of each pulley. This isn't usually critical for belt routing, but it can be helpful for diagnosing performance issues. A significantly undersized or oversized pulley (due to aftermarket parts or damage) could cause problems.

How the Serpentine Belt System Works

The engine's crankshaft turns, which rotates the crankshaft pulley. The serpentine belt wraps around this pulley and transfers that rotational force to all the other accessories. The tensioner pulley maintains the necessary tension to prevent slippage and ensure all accessories are driven efficiently. When the belt is correctly tensioned, it provides the necessary friction against each pulley face to rotate the accessories at their intended speeds. If the belt is too loose, it slips, causing reduced accessory performance (dim headlights, weak power steering, poor AC cooling), squealing noises, and premature belt wear. If the belt is too tight, it can damage the bearings in the accessories and cause the belt to break prematurely.

The path the belt takes is carefully designed to maximize the wrap angle around each pulley. This ensures that each accessory receives enough torque to operate correctly. The idler pulleys are strategically placed to achieve optimal wrap angles.

Real-World Use and Basic Troubleshooting

Here are some common problems and how the diagram can help:

- Squealing Noise: Often caused by a loose belt. Check the tensioner. If the tensioner arm is near its limit of travel, it might be time for a new belt. Verify that the belt is correctly routed, and not rubbing against any other components. Also, inspect the pulleys for signs of wear or damage, such as rust, cracks, or uneven surfaces. A glazed (shiny) belt surface can also cause squealing.

- Accessory Not Working: If the alternator isn't charging, the power steering isn't working, or the A/C isn't cooling, check the belt. Is it broken? Is it slipping? If the belt is intact, use the diagram to verify that the belt is routed correctly to the problematic accessory.

- Belt Keeps Breaking: Could be a misaligned pulley. Use a straight edge to check the alignment of each pulley. A damaged tensioner can also cause premature belt failure.

- Difficulty Installing a New Belt: The diagram is your best friend here! Refer to it *constantly* to ensure you are following the correct path. Use the tensioner release mechanism to create slack in the belt and carefully route it around each pulley. Double-check the routing before releasing the tensioner.

Safety Precautions

Working on the serpentine belt system can be dangerous. Here are some crucial safety considerations:

- Disconnect the Negative Battery Terminal: Prevents accidental electrical shorts, especially when working near the alternator.

- Engine MUST Be Off and Cool: Never work on the system with the engine running or hot. The moving belt can cause severe injury, and hot components can cause burns.

- Keep Hands and Clothing Clear: Keep your hands, clothing, and tools clear of the belt and pulleys while the engine is running.

- Be Aware of Pinch Points: The tensioner mechanism can snap back with significant force. Be cautious when releasing it.

- Wear Safety Glasses: Protect your eyes from debris.

- Alternator: The alternator is a high-voltage component. Even with the battery disconnected, capacitors inside the alternator can store a charge. Avoid touching the terminals directly after disconnecting the battery for a few minutes.

By understanding the 2012 Chrysler 200 2.4L serpentine belt diagram and following these guidelines, you can confidently tackle belt maintenance and troubleshooting. Remember to use the diagram as your reference, take your time, and prioritize safety.

We have the actual diagram available as a downloadable file. Please contact us and we'll get you a copy!