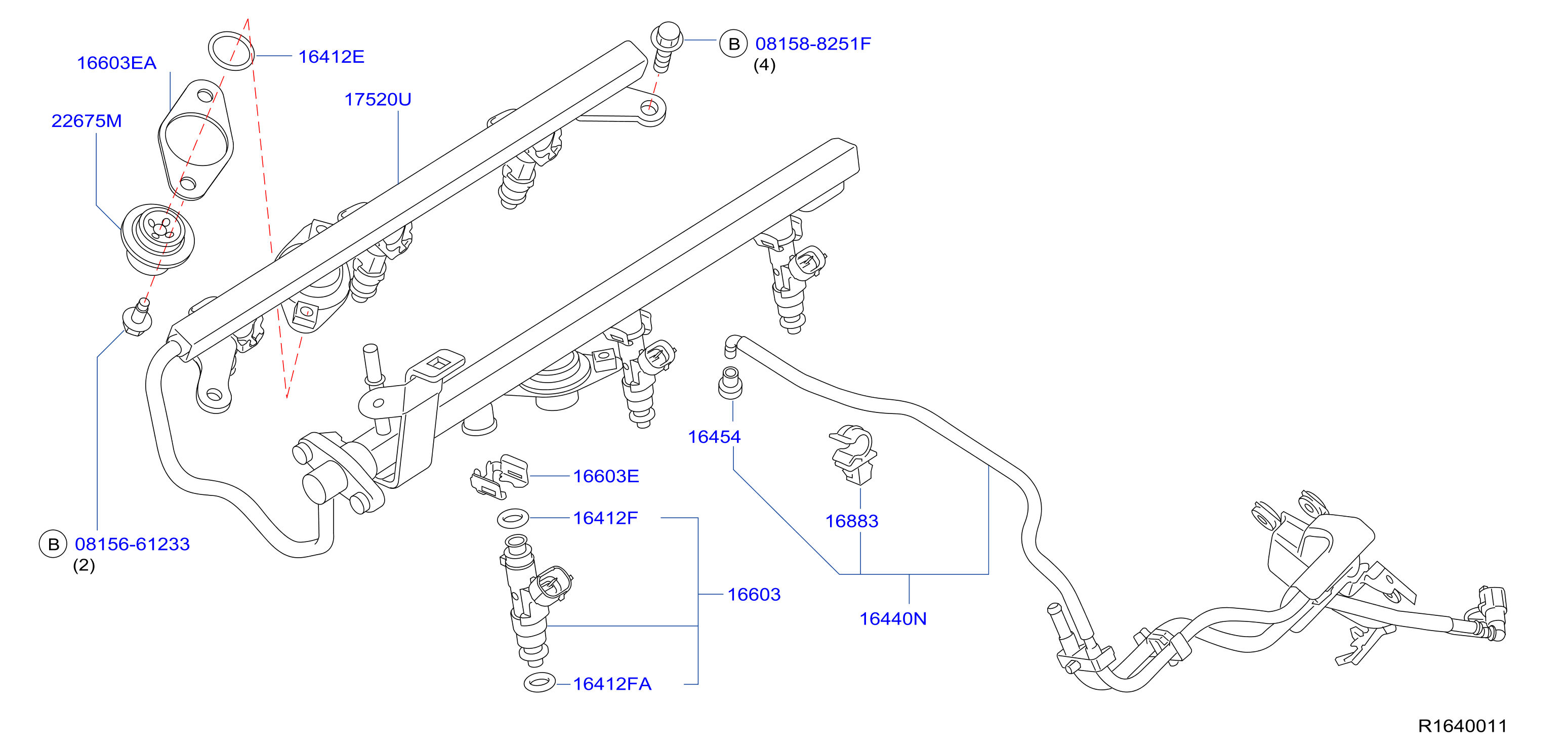

2012 Nissan Pathfinder Fuel Injector Harness Diagram

Alright, let's dive into the fuel injector harness diagram for a 2012 Nissan Pathfinder. Whether you're battling a persistent misfire, upgrading your fuel system, or just want a deeper understanding of your vehicle's inner workings, knowing how to read this diagram is a crucial skill. Consider this your comprehensive guide to understanding the Pathfinder's fuel injection system's wiring.

Purpose: Why You Need This Diagram

Think of the fuel injector harness diagram as the roadmap to your engine's fueling system's electrical pathways. It serves several critical purposes:

- Troubleshooting: When you're dealing with engine performance issues like rough idling, poor acceleration, or failing emissions tests, the fuel injectors are often a prime suspect. The diagram allows you to trace circuits, check for voltage drops, and pinpoint faulty wiring or components.

- Repairing: Damaged wiring from rodents, corrosion, or accidental cuts can lead to injector malfunction. The diagram provides the information necessary to splice wires correctly, replace connectors, and ensure proper circuit integrity.

- Modification and Upgrades: Planning to install larger fuel injectors for increased horsepower? The diagram helps you understand the existing wiring setup, plan for any necessary modifications, and ensure a safe and reliable installation.

- Understanding the System: Even if you're not actively working on your car, the diagram offers a valuable insight into how the fuel injection system is wired and how its components interact.

Key Specs and Main Parts

Before we jump into the diagram itself, let's familiarize ourselves with the key components and their roles in the 2012 Pathfinder's fuel injection system:

- Fuel Injectors: These are electromagnetic valves that spray a precisely measured amount of fuel into the engine's intake manifold. They are controlled by the Engine Control Module (ECM). The 2012 Pathfinder uses multi-port fuel injection (MPFI), meaning each cylinder has its own dedicated injector.

- Fuel Injector Harness: This is the bundle of wires that connects the ECM to each of the fuel injectors. It provides both power and control signals.

- ECM (Engine Control Module): The brain of the operation. The ECM receives data from various sensors (e.g., engine speed, throttle position, oxygen sensors) and uses this information to determine the optimal fuel injection timing and duration.

- Fuel Pump Relay: This relay controls power to the fuel pump, ensuring a constant fuel supply to the fuel injectors. Although it is not part of the injector harness itself, its proper function is essential for the injectors to work.

- Connectors: These provide the physical connections between the wiring harness and the fuel injectors, ECM, and other components. Ensuring these connectors are clean and making solid contact is crucial for proper operation.

- Wiring: The copper wires themselves, insulated to prevent shorts and carrying the electrical signals. Pay attention to the wire gauge (thickness) as this impacts current carrying capacity.

Diagram Symbols: Lines, Colors, and Icons

Understanding the symbols used in the diagram is essential for accurate interpretation. Here's a breakdown of the most common elements:

- Lines: Solid lines represent wires. Dashed lines may indicate shielded wiring or splices within the harness. The thickness of the line does *not* typically indicate wire gauge.

- Colors: Each wire is assigned a specific color code (e.g., Blue/Red, Green/White). These color codes are critical for identifying the correct wires when troubleshooting or performing repairs. The diagram will include a key that translates the abbreviations (BL/R, GR/W, etc.).

- Connectors: Connectors are usually represented by square or rectangular symbols with numbers indicating the pin assignments. These pin numbers correspond to specific wires within the connector.

- Grounds: Ground symbols (often resembling an inverted triangle) indicate points where the wiring harness is connected to the vehicle's chassis, providing a return path for the electrical current.

- Components: Fuel injectors, ECM, relays, and other components are represented by stylized symbols that visually resemble the actual parts. The diagram will label these clearly.

- Splices: Splices (where multiple wires are joined together) are shown as small circles or dots along a wire. They are essential points to check for corrosion or loose connections.

How It Works: The Fuel Injection Circuit

The fuel injection system works by the ECM sending a signal to each fuel injector, telling it to open and spray fuel. Here’s a simplified breakdown:

- The ignition switch is turned on, activating the fuel pump relay, which powers the fuel pump.

- The ECM receives signals from various sensors.

- Based on this data, the ECM calculates the required fuel injection duration (how long the injector should remain open).

- The ECM sends a ground signal to the fuel injector through one of the wires in the harness.

- When grounded by the ECM, the injector solenoid (an electromagnetic coil) energizes, pulling the injector valve open.

- Fuel is sprayed into the intake manifold.

- The ECM stops the ground signal, the injector valve closes, and fuel injection stops.

- This cycle repeats rapidly and precisely for each cylinder.

The harness ensures that the precise timing and voltage needed for each injector reaches the component reliably. Any break in the circuit due to a damaged wire, corroded connector, or faulty ECM can disrupt this process and lead to engine problems.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting steps you can perform using the fuel injector harness diagram:

- Misfire Diagnosis: If you have a misfire code (e.g., P0301 for cylinder #1), use the diagram to locate the fuel injector wiring for that cylinder. Check the connector for damage, corrosion, or loose pins. Use a multimeter to test the continuity of the wiring between the injector connector and the ECM.

- Voltage Drop Testing: With the engine running (carefully!), use a multimeter to measure the voltage drop across each wire in the injector circuit. Excessive voltage drop indicates resistance, which can be caused by corrosion or damaged wiring.

- Injector Resistance Test: Disconnect the fuel injector connector and use a multimeter to measure the resistance across the injector terminals. Compare the readings to the manufacturer's specifications. An out-of-spec reading may indicate a faulty injector.

- Visual Inspection: Carefully inspect the entire fuel injector harness for signs of damage, such as frayed wires, cracked insulation, or rodent damage.

Safety Considerations

Working with automotive electrical systems can be dangerous. Here are some critical safety precautions:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical system to prevent shorts and electrical shock.

- Fuel Pressure: The fuel system is under pressure. Depressurize the fuel system before disconnecting any fuel lines or injectors to avoid fuel spills and potential fire hazards.

- Use Proper Tools: Use properly insulated tools and wear safety glasses to protect yourself from electrical shock and debris.

- Work in a Well-Ventilated Area: Fuel vapors are flammable and can be harmful to breathe. Work in a well-ventilated area.

- Identify High-Voltage Components: While the injector circuit itself isn't high voltage, be aware of other high-voltage components in the engine bay, such as the ignition coils.

Disclaimer: This article provides general information and guidance. Consult a qualified mechanic if you are not comfortable performing these procedures or if you encounter any difficulties.

We have the complete 2012 Nissan Pathfinder fuel injector harness diagram file available for download. Understanding this diagram will empower you to tackle fuel system troubleshooting and repairs with confidence. Good luck!