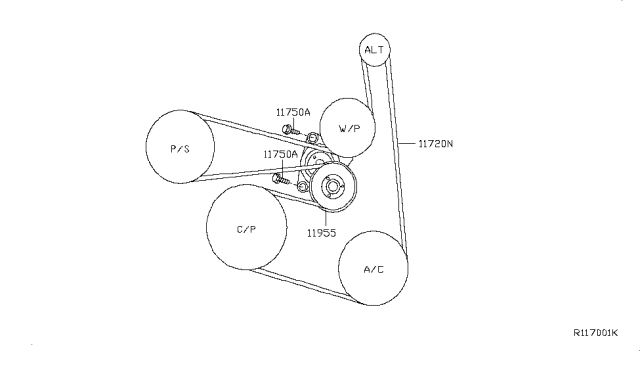

2013 Altima 2.5 Belt Diagram With Electric Power Steering

Alright, let's dive into the serpentine belt diagram for the 2013 Nissan Altima with the 2.5L engine and, importantly, electric power steering (EPS). This configuration is a little different from older hydraulic power steering systems, which impacts the belt routing. Understanding this diagram is crucial for various tasks, from routine maintenance and replacing a worn-out belt to diagnosing system issues and even planning some engine modifications. Knowing the belt path is fundamental to keeping your Altima running smoothly and preventing potentially expensive damage.

Why This Diagram Matters

Think of the serpentine belt as the lifeline of many crucial components in your engine. It's responsible for driving accessories like the alternator, AC compressor, and, in some cases, the water pump. A broken or improperly routed belt can lead to a cascade of problems, including:

- Loss of Power Steering: While you have EPS, the belt drives the alternator. Without a functioning alternator, your EPS system will eventually fail when the battery is depleted, leading to difficult steering.

- Overheating: If the belt drives the water pump (some configurations exist), coolant won't circulate properly, causing the engine to overheat.

- Battery Drain: A slipping or broken belt prevents the alternator from charging the battery.

- AC Failure: No belt, no AC, which can be a real drag, especially in the summer.

Having a clear diagram on hand allows you to:

- Properly route a new belt during replacement.

- Quickly diagnose issues by visually inspecting belt condition and routing.

- Confirm the correct belt length and type when purchasing a replacement.

- Understand the relationship between different engine components.

Key Specs and Main Parts

For the 2013 Altima 2.5L with EPS, the typical serpentine belt configuration includes these components:

- Crankshaft Pulley (or Damper): This is the driving force, connected directly to the engine's crankshaft.

- Alternator Pulley: Powered by the belt to generate electricity.

- AC Compressor Pulley: Engages when you turn on the air conditioning.

- Tensioner Pulley: Spring-loaded and automatically maintains proper belt tension. It's crucial for belt longevity and preventing slippage.

- Idler Pulley: A smooth pulley that guides the belt and changes its direction. Not all configurations have one.

Key specs to note are:

- Belt Length: This will vary slightly depending on whether the water pump is driven by the belt or is electrically driven. Consult the parts catalog or the diagram itself for the correct length.

- Belt Type: Serpentine belts are typically made of EPDM (ethylene propylene diene monomer) rubber, which offers good resistance to heat and wear.

Symbols and Diagram Interpretation

Understanding the symbols on the diagram is essential. Here's a breakdown:

- Solid Line: Represents the path of the serpentine belt itself.

- Dashed Line (if present): May indicate the back of the belt, illustrating how it wraps around a pulley.

- Arrows: Indicate the direction of rotation for each pulley. This is critical for understanding how the belt should be routed.

- Component Labels: Each pulley will be labeled with its corresponding component (e.g., ALT for alternator, AC for AC compressor, CRANK for crankshaft).

- Tensioner Indication: The tensioner pulley is often marked with a spring symbol or a "TENSIONER" label. The diagram will also show the direction in which to move the tensioner to relieve belt tension.

Pay close attention to the routing direction. The belt needs to follow the exact path shown in the diagram. Incorrect routing can lead to component failure, belt damage, and even engine damage.

How It Works

The 2013 Altima 2.5L serpentine belt system is relatively straightforward. The crankshaft pulley, driven by the engine, provides the power to turn all the other pulleys. The belt wraps around these pulleys, transferring the rotational force. The tensioner pulley automatically adjusts to maintain the correct belt tension, compensating for belt stretch and wear. With the EPS system, the alternator is crucial. It powers the EPS motor, which provides steering assist. If the belt fails and the alternator stops spinning, the battery will drain, and you'll lose power steering assist once the battery's charge is depleted.

Real-World Use: Basic Troubleshooting Tips

Here are some common issues and how the diagram can help:

- Squealing Belt: Often caused by a loose belt, a worn belt, or misaligned pulleys. The diagram helps you visually inspect the belt path and tensioner. Check if the tensioner is moving freely and maintaining adequate pressure. A worn or glazed belt will need replacement.

- Belt Slippage: Can be caused by a worn belt, oil contamination, or a faulty tensioner. The diagram helps you identify potential sources of contamination (leaks) and allows you to check the tensioner's operation.

- Belt Breakage: Often a sign of a seized pulley, excessive wear, or incorrect belt routing. The diagram will show you if the belt is routed correctly. Manually rotate each pulley to check for resistance or seizing.

Before replacing the belt, take a picture or make a detailed sketch of the current belt routing. This will be invaluable if you get confused during the replacement process.

Safety First!

Working on the serpentine belt system involves several safety considerations:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components. This prevents accidental shorts.

- Hot Engine: Never work on the engine when it's hot. Allow it to cool completely to avoid burns.

- Moving Parts: Keep your hands, tools, and clothing clear of the belt and pulleys when the engine is running. Even at idle, the belt moves quickly and can cause serious injury.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Pay Attention to the Tensioner: The spring-loaded tensioner can snap back with considerable force. Use the correct tools and techniques to relieve tension safely.

Special Note on the Alternator: The alternator produces high voltage. Even with the battery disconnected, residual voltage can be present. Be cautious when working around the alternator terminals.

With the knowledge from this article and the detailed diagram we have available, you'll be well-equipped to tackle serpentine belt maintenance and troubleshooting on your 2013 Nissan Altima 2.5L with EPS. Remember to always prioritize safety and consult the vehicle's service manual for specific procedures and torque specifications.