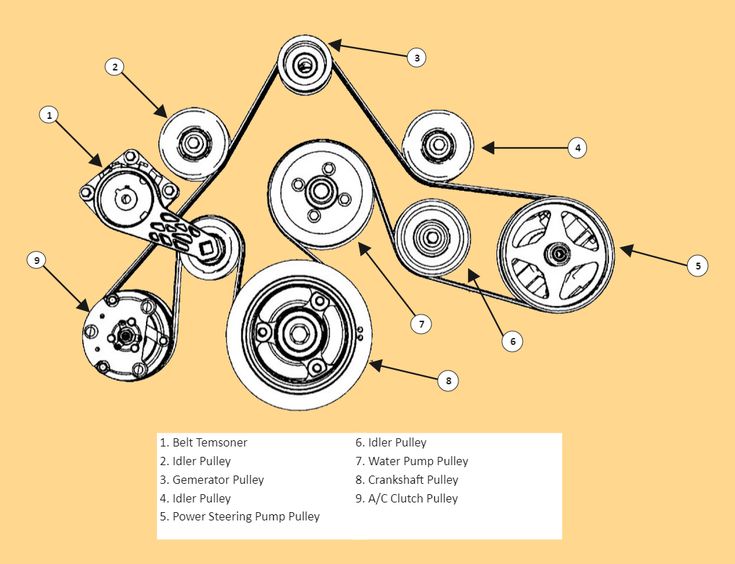

2013 Gmc Terrain 3.6 Litre Serpentine Belt Routing Diagram

The 2013 GMC Terrain, equipped with the 3.6-liter V6 engine (code LFX), utilizes a serpentine belt system to drive several crucial engine components. Understanding the serpentine belt routing diagram for this vehicle is invaluable for performing routine maintenance, diagnosing belt-related issues, and even for engine swaps or modifications. This article will provide a detailed breakdown of the diagram, its purpose, key components, functionality, and troubleshooting tips, empowering you to confidently tackle belt-related tasks on your Terrain.

Purpose of the Serpentine Belt Routing Diagram

The serpentine belt routing diagram serves as a visual guide illustrating the precise path the serpentine belt takes as it wraps around the various pulleys connected to engine accessories. Its primary purposes are:

- Maintenance and Replacement: When replacing a worn or damaged serpentine belt, the diagram ensures the new belt is installed correctly, preventing improper tensioning or incorrect routing, which can lead to component damage or failure.

- Troubleshooting: A quick reference to the diagram helps diagnose belt slippage, noise, or component failure by verifying the correct belt path and tension.

- Engine Repair: During engine repairs or component replacements (e.g., alternator, power steering pump), the diagram aids in the removal and reinstallation of the serpentine belt.

- Learning and Understanding: For those new to automotive mechanics, the diagram provides a visual representation of how the engine accessories are driven by a single belt, improving overall understanding of engine operation.

Key Specs and Main Parts

Before diving into the diagram, let's familiarize ourselves with the key components of the serpentine belt system on the 2013 GMC Terrain 3.6L:

- Crankshaft Pulley: The main pulley driven directly by the engine's crankshaft. It provides the rotational force for the entire serpentine belt system.

- Alternator Pulley: Drives the alternator, responsible for charging the battery and powering the vehicle's electrical system.

- Power Steering Pump Pulley: Drives the power steering pump, which provides hydraulic assistance for steering.

- Air Conditioning Compressor Pulley: Drives the AC compressor, responsible for cooling the vehicle's cabin.

- Idler Pulley(s): Smooth, non-driven pulleys used to guide the belt around the other components, ensuring proper wrap angle and tension.

- Tensioner Pulley: A spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. This is crucial for preventing slippage and ensuring proper operation of all driven components.

- Serpentine Belt: A long, multi-ribbed belt made of durable rubber compound, designed to efficiently transmit power from the crankshaft to the various engine accessories.

The 2013 GMC Terrain 3.6L typically uses a 6-rib serpentine belt. The specific length will vary slightly depending on optional equipment, so always consult the correct part number based on your VIN when purchasing a replacement.

Symbols and Diagram Interpretation

Serpentine belt routing diagrams use standardized symbols to represent different components and belt paths. Here's a breakdown of common symbols:

- Solid Lines: Indicate the primary path of the serpentine belt around the pulleys. The thickness of the line may sometimes denote whether the belt runs on the grooved (ribbed) side or the smooth side of the pulley.

- Dotted Lines: Often used to indicate the back side (smooth side) of the belt and its contact with a pulley. This is important for understanding which side of the belt is driving which component.

- Arrows: Show the direction of belt travel. These are essential for ensuring the belt is routed in the correct orientation.

- Pulleys: Represented as circles. Labels or abbreviations (e.g., ALT for alternator, P/S for power steering) usually identify the component the pulley drives.

- Tensioner: Depicted as a pulley with an arrow indicating the direction of tension application. The tensioner is critical for maintaining proper belt tension.

Pay close attention to the orientation of the pulleys in the diagram. Is the belt wrapping around the pulley from the top or the bottom? This will determine the correct routing path. Look for any labeling that clarifies the function of each component.

How It Works

The serpentine belt system operates on a simple principle: the crankshaft's rotational energy is transferred to other engine accessories via the serpentine belt. The crankshaft pulley, directly connected to the rotating crankshaft, drives the serpentine belt. As the belt travels around the various pulleys, it causes them to rotate, powering the corresponding components (alternator, power steering pump, AC compressor, etc.).

The tensioner pulley plays a vital role in maintaining proper belt tension. The spring-loaded mechanism in the tensioner automatically adjusts to compensate for belt stretch or wear, ensuring that the belt maintains adequate grip on all the pulleys. Insufficient tension will cause belt slippage, leading to reduced performance of the driven components and potentially damaging the belt itself. Excessive tension can overstress the belt and bearings in the driven components, shortening their lifespan.

Proper alignment of all pulleys is essential for optimal serpentine belt system operation. Misaligned pulleys can cause the belt to wear prematurely, make noise, and even jump off the pulleys.

Real-World Use and Basic Troubleshooting

Here are some common problems related to the serpentine belt and how the routing diagram can help you troubleshoot:

- Squealing Noise: Often indicates a slipping belt. Check the belt for wear, cracks, or glazing. Verify the tensioner is functioning correctly and maintaining proper tension. The diagram helps confirm the belt is routed correctly.

- Battery Light On: Could indicate a faulty alternator, but also a slipping belt preventing the alternator from spinning at the required speed. Use the diagram to ensure the belt is properly routed around the alternator pulley.

- Power Steering Issues: Difficulty steering can be caused by a failing power steering pump, but also by a slipping belt preventing the pump from operating effectively. Check the belt's routing around the power steering pump pulley using the diagram.

- Overheating: While not directly driven by the serpentine belt on this model, a slipping belt affecting the alternator can lead to reduced cooling fan performance if the battery voltage drops too low.

- Visible Belt Damage: Cracks, fraying, or missing ribs indicate a worn belt that needs replacement. Use the diagram to ensure the new belt is routed correctly.

If you suspect a problem with the serpentine belt system, always visually inspect the belt and all pulleys for damage or wear. Use a belt tension gauge to verify the belt tension is within the manufacturer's specifications.

Safety Considerations

Working on the serpentine belt system can be dangerous due to the proximity of moving engine parts. Here are some important safety precautions:

- Disconnect the Battery: Before working on any part of the engine, disconnect the negative battery cable to prevent accidental starting.

- Work in a Well-Ventilated Area: Avoid working in enclosed spaces where exhaust fumes can accumulate.

- Keep Hands and Clothing Clear: Ensure hands, clothing, and tools are clear of the serpentine belt and pulleys when the engine is running.

- Be Mindful of Hot Components: Allow the engine to cool down before working on the serpentine belt system to avoid burns.

- Use Proper Tools: Use the correct tools for the job, such as a serpentine belt tool for releasing tension on the tensioner pulley.

The tensioner pulley itself can be a hazard. The spring is under considerable tension, and if released improperly, it can cause serious injury. Always use the correct tool to relieve the tension on the pulley slowly and carefully.

Understanding the serpentine belt routing diagram for your 2013 GMC Terrain 3.6L is essential for proper maintenance and repair. This detailed guide, combined with careful observation and safe practices, will empower you to confidently tackle any belt-related issue.

We have a high-resolution, printable serpentine belt routing diagram specific to the 2013 GMC Terrain 3.6L engine readily available. You can download the file to keep it handy for your next maintenance or repair task.