2014 Chrysler Town And Country 3.6 Serpentine Belt Diagram

The serpentine belt in your 2014 Chrysler Town and Country with the 3.6L Pentastar engine is a crucial component that drives several key engine accessories. Understanding its routing, tensioning, and overall system is paramount for effective maintenance, troubleshooting, and repairs. This article provides a detailed technical overview of the 2014 Town and Country's serpentine belt diagram, equipping you, the experienced DIYer, with the knowledge necessary to tackle common belt-related issues.

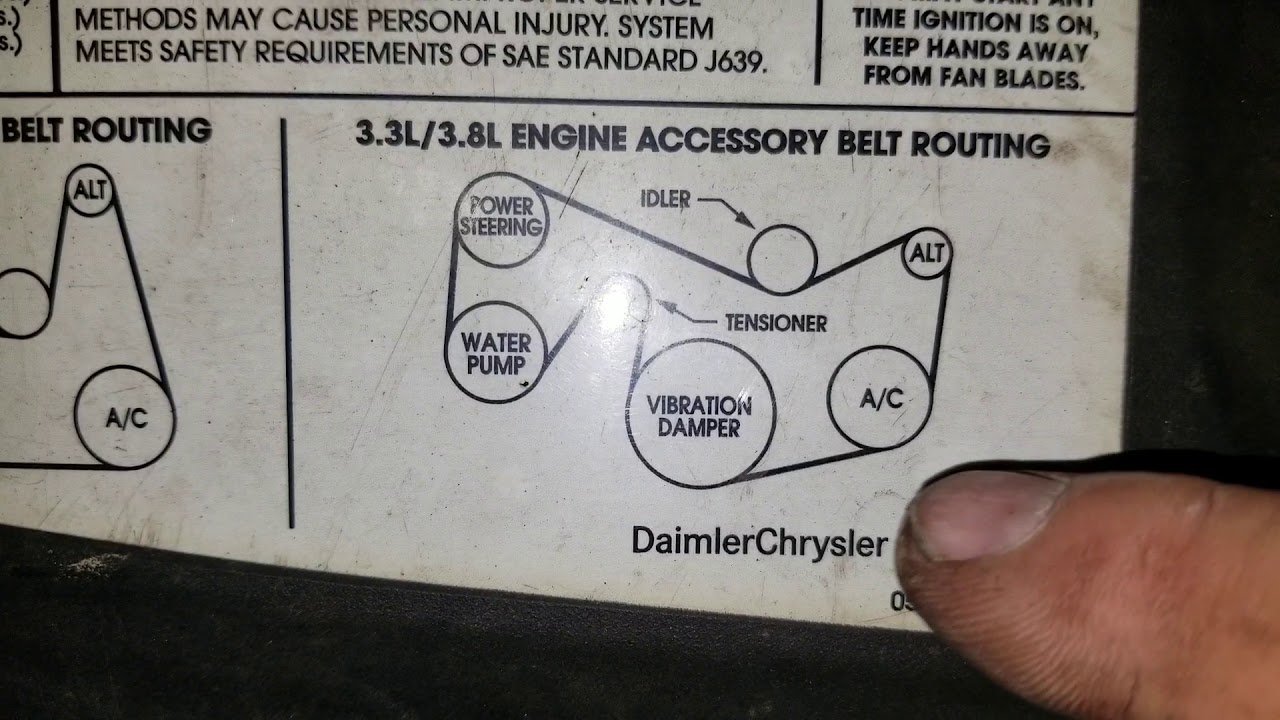

Purpose of the Serpentine Belt Diagram

A serpentine belt diagram serves as a visual guide to the correct routing of the serpentine belt. This is vital for several reasons:

- Correct Installation: Ensures the belt is properly aligned on all pulleys, preventing slippage, premature wear, and potential damage to accessories.

- Troubleshooting: Helps diagnose issues related to belt noise, accessory malfunction, or belt failure by identifying potential misalignment or worn components.

- Maintenance: Essential during belt replacement, accessory removal/installation (e.g., alternator, power steering pump), and tensioner adjustments.

- Learning: Provides a valuable resource for understanding how the engine accessories are driven and their relationship to the crankshaft.

Without a diagram, installing a new belt or reinstalling an existing one after a repair can be a frustrating and potentially damaging endeavor. A misrouted belt will likely fail quickly and may also damage the accessories it's supposed to drive.

Key Specs and Main Parts of the Serpentine Belt System

The serpentine belt system on the 2014 Chrysler Town and Country 3.6L consists of several key components, each playing a specific role:

- Serpentine Belt: A single, long belt made of rubber or a synthetic compound that transmits rotational force from the crankshaft to various accessories.

- Crankshaft Pulley (Damper): Connected directly to the crankshaft, this pulley is the driving force behind the entire system. It often incorporates a torsional damper to minimize engine vibrations.

- Alternator Pulley: The alternator, responsible for charging the battery and providing electrical power to the vehicle, is driven by the serpentine belt.

- Power Steering Pump Pulley: The power steering pump provides hydraulic assistance to the steering system, making it easier to turn the steering wheel.

- Air Conditioning (A/C) Compressor Pulley: The A/C compressor is responsible for compressing the refrigerant in the air conditioning system.

- Water Pump Pulley: The water pump circulates coolant throughout the engine, preventing overheating.

- Idler Pulley(s): Smooth pulleys that guide the belt along its path and maintain proper tension. These pulleys don't drive any accessories.

- Belt Tensioner: A spring-loaded or hydraulic device that automatically maintains the correct tension on the serpentine belt, compensating for belt stretch and temperature changes. The tensioner is critical for proper belt operation.

Knowing the location and function of each component is crucial for accurate troubleshooting and repair. The belt tensioner is particularly important to understand, as it allows for belt removal and installation.

Understanding Serpentine Belt Diagram Symbols

Serpentine belt diagrams use specific symbols to convey information about the belt's routing and the components involved. Here's a breakdown of common symbols:

- Solid Line: Represents the path of the serpentine belt. The direction of the line indicates the direction of belt travel.

- Dotted or Dashed Line: May indicate the "backside" or smooth side of the belt contacting a pulley. This is important to note as the ribbed side of the belt engages the grooved pulleys, while the smooth side is used for idler pulleys.

- Arrows: Indicate the direction of rotation for each pulley. This helps confirm that the belt is routed correctly and that accessories are rotating in the intended direction.

- Pulley Icons: Simplified representations of each pulley, often labeled with abbreviations indicating their function (e.g., ALT for alternator, P/S for power steering).

- Tensioner Symbol: A stylized representation of the belt tensioner, often including an arrow indicating the direction to move the tensioner to relieve belt tension.

- Component Labels: Abbreviations or full names of each component (e.g., Crankshaft, Water Pump) to identify them clearly.

Pay close attention to the direction of the arrows on the pulleys. An incorrectly routed belt can cause accessories to rotate in the wrong direction, leading to damage. Also, look for indicators showing which side of the belt (grooved or smooth) is touching the pulley.

How the Serpentine Belt System Works

The serpentine belt system is a relatively simple yet vital mechanism. The crankshaft pulley, driven by the engine, provides the rotational force that powers all the connected accessories. As the crankshaft rotates, it turns the serpentine belt, which in turn drives the alternator, power steering pump, A/C compressor, water pump, and any other belt-driven accessories. The belt tensioner maintains the correct tension on the belt, preventing slippage and ensuring efficient power transfer.

The routing of the belt is carefully designed to maximize contact with each pulley, optimizing power transfer. The belt wraps around each pulley in a specific sequence, determined by the engine design and accessory placement. The idler pulleys help guide the belt along this path and maintain proper tension.

Real-World Use and Basic Troubleshooting Tips

Here are some common issues related to the serpentine belt system and how the diagram can help:

- Squealing Noise: Often caused by a loose or worn belt. Check the belt tensioner and belt condition. The diagram helps you visually confirm that the belt is correctly routed and properly contacting each pulley.

- Accessory Malfunction: If an accessory stops working (e.g., power steering failure, A/C not cooling), check the serpentine belt to ensure it's intact and properly routed. The diagram confirms whether the belt drives that specific accessory.

- Belt Slippage: Indicated by a chirping or squealing noise, especially under load. Check for worn pulleys, a weak tensioner, or a contaminated belt. The diagram helps identify which pulleys might be causing the slippage.

- Visual Inspection: Regularly inspect the belt for cracks, fraying, or missing chunks. A worn belt is more prone to failure. The diagram allows you to visually verify that the belt is routed as designed before assuming other problems.

- Tensioner Movement: Excessive tensioner movement or a tensioner that is fully extended indicates a worn or stretched belt. The diagram aids in finding the location of the tensioner for assessment.

Before replacing the serpentine belt, it's always a good idea to inspect the pulleys for any signs of damage or wear. A damaged pulley can quickly ruin a new belt. If you are unsure of your work, it's always best to consult with a certified mechanic.

Safety Precautions

Working on the serpentine belt system can be hazardous. Always disconnect the negative battery cable before starting any work. The engine must be off and cool.

- Moving Parts: The serpentine belt and pulleys are moving parts. Keep your hands, clothing, and tools clear of the system when the engine is running.

- Tensioner Spring: The belt tensioner is under spring tension. Use the appropriate tool to relieve the tension before removing the belt. Releasing the tension incorrectly can cause injury.

- Hot Surfaces: The engine components can be very hot. Allow the engine to cool completely before working on the serpentine belt system.

A mistake here can damage the vehicle or cause personal injury. Always prioritize safety.

We have a high-resolution serpentine belt diagram file available for download. This diagram provides a clear and detailed visual representation of the belt routing for your 2014 Chrysler Town and Country 3.6L, aiding in proper maintenance and repair.