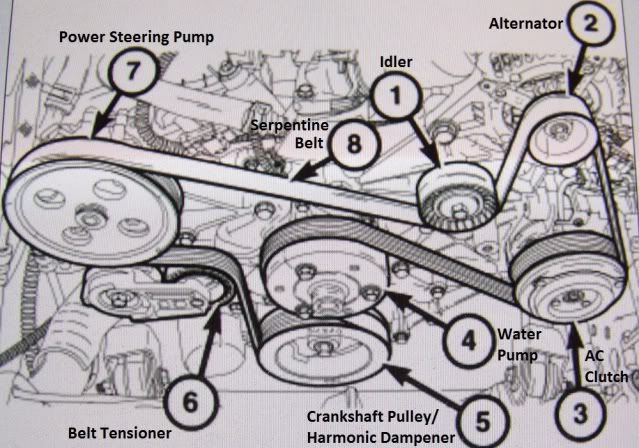

2014 Jeep Grand Cherokee 3.6 Serpentine Belt Diagram

The serpentine belt, also known as the accessory drive belt, is a critical component in your 2014 Jeep Grand Cherokee's 3.6L Pentastar V6 engine. It's responsible for powering several essential systems, including the alternator (which charges the battery), the power steering pump (which provides steering assistance), the air conditioning compressor (which cools the cabin), and sometimes the water pump (which circulates coolant to regulate engine temperature). Understanding the serpentine belt routing and how it interacts with these components is crucial for maintenance, troubleshooting, and repair. This article will delve into the 2014 Jeep Grand Cherokee 3.6L serpentine belt diagram, explaining its purpose, key components, symbols, functionality, and practical use.

Purpose of the Serpentine Belt Diagram

Why bother with a serpentine belt diagram? Here's why it's indispensable for the DIY mechanic:

- Belt Replacement: The primary reason is to ensure correct belt routing during replacement. Incorrect routing can lead to system failure, overheating, and even engine damage.

- Troubleshooting: A visual aid like the diagram helps to identify which accessory is malfunctioning based on symptoms. For example, if your power steering isn't working, the diagram can help verify the belt is properly engaged with the power steering pump pulley.

- Preventative Maintenance: The diagram allows you to visually inspect the belt's path and confirm proper alignment and tension.

- Learning: Understanding the serpentine belt system is a great way to learn more about how your engine operates and the interconnectedness of its various components.

Key Specs and Main Parts

Before diving into the diagram, let's define the critical parts within the serpentine belt system of the 2014 Jeep Grand Cherokee 3.6L:

- Serpentine Belt: A single, continuous belt that drives multiple engine accessories. Its made of rubber with reinforcement cords for strength and flexibility.

- Crankshaft Pulley (or Damper): Located at the bottom of the engine, driven directly by the crankshaft. This pulley initiates the belt's motion and drives all other accessories.

- Alternator Pulley: Driven by the serpentine belt, powering the alternator to generate electricity.

- Power Steering Pump Pulley: Spins the power steering pump, providing hydraulic assistance for steering.

- Air Conditioning Compressor Pulley: Engages when the air conditioning is activated, compressing refrigerant to cool the cabin.

- Idler Pulleys: Smooth pulleys that guide the belt and maintain proper tension without driving any accessories. They reduce vibrations and ensure the belt follows the designed path.

- Tensioner Pulley: A spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. It compensates for belt stretch and wear. A worn tensioner can cause belt slippage and noise.

- Water Pump Pulley: (In some configurations of the 3.6L Pentastar) Driven by the belt to circulate coolant, preventing the engine from overheating.

Understanding the Symbols in the Diagram

Serpentine belt diagrams use symbols to represent the various components and their relationships. Deciphering these symbols is crucial to interpreting the diagram correctly. Here's a breakdown of common symbols:

- Solid Lines: Represent the path of the serpentine belt. The thickness of the line doesn't necessarily indicate belt size, just visual clarity.

- Arrows: Indicate the direction of rotation for each pulley. This is vital to ensure the belt is routed correctly to maintain the proper accessory function.

- Circles/Discs: Represent pulleys. Often, the diagram will label each pulley (e.g., ALT for alternator, P/S for power steering).

- Text Labels: Clearly identify each component, specifying its function within the system.

- Dashed Lines (Sometimes): May indicate the backside (smooth side) of the belt contacting a pulley or the direction of force applied by the tensioner.

The direction of the arrows is extremely important. Ensure the diagram matches the physical orientation and rotation of the pulleys on your engine. If you are unsure about which diagram to follow, double check against the actual layout on the engine.

How It Works: The Serpentine Belt's Function

The serpentine belt system functions based on a simple principle: rotational force transfer. The crankshaft, driven by the engine's combustion process, rotates the crankshaft pulley. This pulley, in turn, drives the serpentine belt, which wraps around various accessory pulleys. The friction between the belt and the pulleys transfers the rotational force, causing the accessories (alternator, power steering pump, etc.) to spin and perform their respective functions.

The tensioner pulley plays a crucial role in maintaining optimal belt tension. As the belt stretches over time due to wear and tear, the tensioner automatically adjusts to compensate, ensuring the belt remains snug against the pulleys and prevents slippage. Slippage results in reduced accessory performance and can generate squealing or chirping noises.

Real-World Use: Basic Troubleshooting Tips

The serpentine belt system is relatively robust, but issues can arise. Here are some common problems and how the diagram can aid in diagnosis:

- Squealing or Chirping Noise: Often indicates a loose belt, glazed belt surface, or a failing pulley bearing. Use the diagram to check the belt's routing and inspect the tensioner. Spraying a small amount of belt dressing can temporarily eliminate the noise, but it's a band-aid solution; the underlying problem needs to be addressed.

- Accessory Failure: If your alternator isn't charging or your power steering is weak, consult the diagram to ensure the belt is properly engaging with the corresponding pulley. Check the belt for cracks, fraying, or missing chunks.

- Belt Slippage: Can be caused by a worn belt, a faulty tensioner, or excessive load on an accessory (e.g., a failing air conditioning compressor). The diagram helps verify the belt path and tensioner function.

- Belt Breakage: A broken belt is a serious issue, rendering all accessories inoperative. Inspect all pulleys for damage or misalignment that may have caused the belt to fail. The diagram is critical for proper re-installation of the replacement belt.

When troubleshooting, always visually inspect the entire belt path according to the diagram. Look for signs of wear, damage, or misalignment. Also, listen for unusual noises coming from the pulleys. A stethoscope (or even a long screwdriver placed against the pulley housing, with the handle held to your ear) can help pinpoint the source of the noise.

Safety Considerations

Working on the serpentine belt system can be dangerous if proper precautions are not taken:

- Disconnect the Battery: Before working on any part of the electrical system, disconnect the negative battery terminal to prevent accidental shorts or shocks.

- Engine OFF: Never work on the serpentine belt system while the engine is running. The rotating components pose a serious entanglement hazard.

- Hot Components: Allow the engine to cool completely before working on the system. Exhaust manifolds and other engine parts can become extremely hot.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Proper Tools: Use the correct tools for the job. A serpentine belt tool can make removing and installing the belt much easier and safer.

Always be aware of the potential for injury when working around rotating engine components.

Never put your hands or tools near the belt or pulleys while the engine is running.

The tensioner pulley has a strong spring. Exercise caution when releasing it, as it can snap back with considerable force.

We have access to the detailed 2014 Jeep Grand Cherokee 3.6L Serpentine Belt Diagram. It includes detailed routing and component callouts. Download the file and save it for future reference. This diagram will be a valuable resource for maintaining and repairing your vehicle's serpentine belt system.