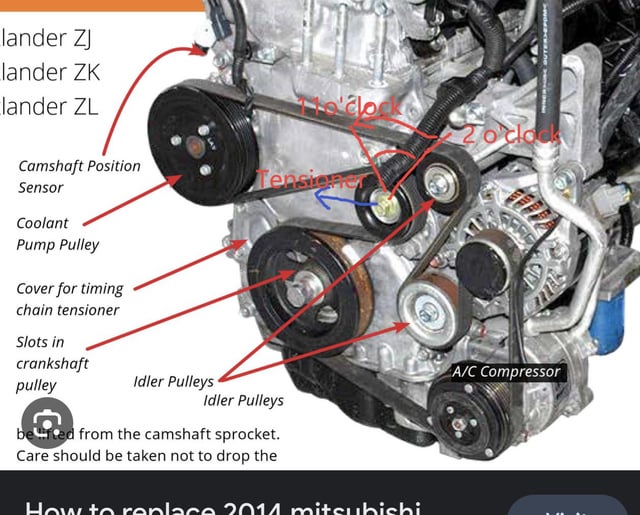

2014 Mitsubishi Outlander Serpentine Belt Diagram

The serpentine belt in your 2014 Mitsubishi Outlander is a critical component, responsible for driving several essential accessories. Understanding its layout and operation is crucial for preventative maintenance, diagnosing issues, and performing necessary repairs. This article provides a detailed breakdown of the 2014 Outlander's serpentine belt diagram, aiming to empower experienced DIYers with the knowledge needed to tackle related tasks confidently.

Purpose and Importance

The serpentine belt diagram serves several vital purposes:

- Repair and Replacement: When replacing a worn or damaged serpentine belt, the diagram ensures correct routing. Incorrect routing can lead to component failure, premature belt wear, and even engine damage.

- Troubleshooting: A squealing belt, power steering loss, or charging issues can often be traced back to a problem with the serpentine belt system. The diagram helps identify the components involved and assess their condition.

- Preventative Maintenance: Familiarity with the belt's path allows for easier inspection of pulleys, tensioners, and the belt itself for signs of wear or damage during routine maintenance.

- Learning and Understanding: Studying the diagram helps understand how the various engine accessories are driven and interconnected, improving overall automotive knowledge.

Key Specs and Main Parts

Before diving into the diagram, let's identify the primary components of the serpentine belt system in a 2014 Mitsubishi Outlander (Note: There might be slight variations based on engine type – 2.0L or 2.4L).

- Serpentine Belt: A long, continuous belt made of rubber or a synthetic material, designed to drive multiple accessories. Specific length and rib count vary based on engine type.

- Crankshaft Pulley (Damper): Connected to the crankshaft, this pulley is the driving force behind the entire system. Its rotation, powered by the engine, turns the serpentine belt.

- Alternator Pulley: Driven by the serpentine belt, the alternator generates electricity to power the vehicle's electrical system and charge the battery.

- Power Steering Pump Pulley: Rotated by the serpentine belt, the power steering pump provides hydraulic assistance for easier steering.

- Air Conditioning (A/C) Compressor Pulley: The A/C compressor, also driven by the belt, circulates refrigerant to cool the cabin.

- Idler Pulley(s): Smooth pulleys used to guide the belt and maintain proper tension and routing. They do not drive any specific component.

- Tensioner Pulley (Automatic Belt Tensioner): This spring-loaded or hydraulic mechanism applies consistent tension to the serpentine belt. It automatically adjusts for belt stretch and wear. It is very important to ensure this is working as expected.

Important Specification: The serpentine belt's part number is crucial for replacement. Refer to your vehicle's owner's manual or a reliable auto parts retailer for the correct part number. Using the wrong belt can lead to improper fit, reduced performance, and potential damage to the accessories.

Serpentine Belt Diagram Symbols and Interpretation

Understanding the symbols and conventions used in the diagram is key to its effective use.

- Solid Lines: Represent the path of the serpentine belt. The thicker the line, the more prominent the belt run.

- Pulleys: Typically depicted as circles. Some diagrams may include labels indicating the component driven by each pulley (e.g., ALT for alternator, P/S for power steering).

- Arrows: Indicate the direction of rotation for each pulley. This is particularly important for understanding belt routing and identifying potential problems.

- Tensioner: Usually represented by a symbol depicting a spring or a hinged arm with a pulley.

- Dashed Lines: May indicate the back side of the belt (the smooth side) contacting a pulley, or the direction in which to move the tensioner to relieve tension.

Example: A solid line connecting the crankshaft pulley to the alternator pulley indicates that the serpentine belt directly drives the alternator from the crankshaft. An arrow pointing clockwise on the alternator pulley shows the direction of its rotation.

How It Works

The serpentine belt system operates on the principle of rotational power transfer. The crankshaft, powered by the engine's combustion, spins the crankshaft pulley. The serpentine belt, wrapped around this pulley and other accessory pulleys, transfers this rotational force to the alternator, power steering pump, A/C compressor, and other driven components. The tensioner maintains consistent belt tension, preventing slippage and ensuring efficient power transfer.

The automatic belt tensioner is crucial for maintaining proper belt tension as the belt stretches over time. Inside the tensioner is a spring or hydraulic piston that provides continuous pressure on the tensioner pulley. When the belt stretches, the tensioner automatically adjusts its position to compensate, keeping the belt tight and preventing slippage. If the tensioner fails, the belt will become loose, leading to squealing noises, reduced accessory performance, and potential damage.

Real-World Use and Troubleshooting

Here are some common problems and how the serpentine belt diagram can help:

- Squealing Noise: A squealing or chirping noise often indicates a slipping serpentine belt. The diagram can help identify the pulleys that are most likely causing the slippage (often those with the smallest wrap angle). Check the belt for glazing, cracks, or missing ribs. Inspect the pulleys for damage or contamination (oil, coolant). The tensioner's function can also be checked to make sure it still provides proper tension. A worn tensioner will bounce or rattle.

- Loss of Power Steering: If the power steering suddenly becomes difficult, the serpentine belt might have broken or slipped off the power steering pump pulley. The diagram confirms if the power steering pump is driven by the serpentine belt and helps visualize the belt routing for inspection.

- Charging Problems: A malfunctioning alternator can lead to a dead battery. The diagram will show if the serpentine belt drives the alternator. A slipping belt could prevent the alternator from generating enough power.

- Overheating: On some vehicles, the water pump is driven by the serpentine belt. A broken or slipping belt can stop the water pump from circulating coolant, leading to overheating.

- Visual Inspection: Regularly inspect the serpentine belt for signs of wear, such as cracks, fraying, or missing ribs. Replace the belt if any of these conditions are present. Use the diagram to verify that the belt is correctly routed and that all pulleys are properly aligned.

Safety Considerations

Working around the serpentine belt system involves inherent risks. Here are some crucial safety precautions:

- Disconnect the Battery: Before working on any part of the serpentine belt system, disconnect the negative terminal of the battery to prevent accidental starting of the engine.

- Hot Engine: Never work on the serpentine belt system while the engine is hot. Allow the engine to cool down completely to avoid burns.

- Moving Parts: Keep hands, clothing, and tools clear of the serpentine belt and pulleys when the engine is running. The rotating components can cause serious injuries.

- Tensioner Safety: The automatic belt tensioner is under significant spring pressure. Use the correct tool (typically a serpentine belt tool or wrench) to relieve the tension and remove the belt safely. Releasing the tension without the proper tool can result in injury.

- Eye Protection: Always wear safety glasses to protect your eyes from debris or flying objects.

Caution: The crankshaft pulley is a high-torque component. Avoid trying to hold it still by hand while loosening or tightening the crankshaft bolt. Use appropriate locking tools.

We have a detailed serpentine belt diagram file specifically for the 2014 Mitsubishi Outlander. Feel free to reach out and request to download the diagram for your reference.