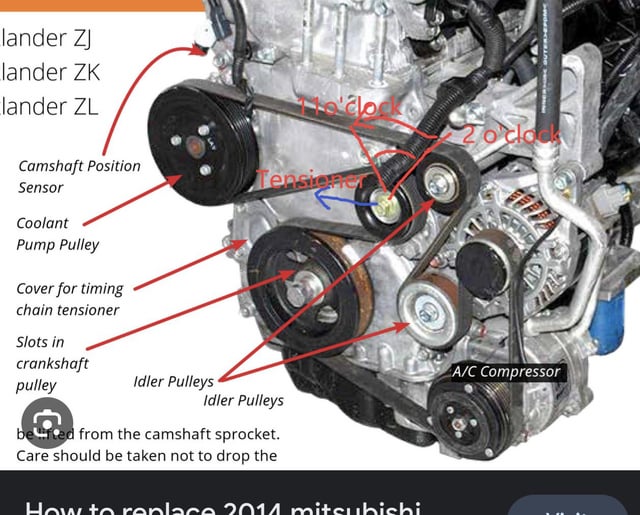

2016 Mitsubishi Outlander Serpentine Belt Diagram

The serpentine belt, also known as the accessory drive belt, is a critical component in your 2016 Mitsubishi Outlander. It's responsible for powering several essential systems, including the alternator (which charges the battery), the power steering pump (for easy steering), the air conditioning compressor (for cooling), and sometimes the water pump (for engine cooling, though on some Outlander models this is driven by the timing chain). Understanding its routing and condition is vital for preventative maintenance and troubleshooting.

Purpose of the Serpentine Belt Diagram

A serpentine belt diagram is essential for several reasons:

- Correct Belt Installation: The belt must be routed correctly around the pulleys. An incorrectly installed belt will not function, and can even damage components.

- Troubleshooting Belt Issues: The diagram allows you to inspect the belt's path and identify potential issues like misalignment or damaged pulleys.

- Belt Replacement: When replacing the belt, the diagram provides a visual reference for the correct routing, ensuring a smooth and trouble-free installation.

- General Understanding: Familiarizing yourself with the belt system enhances your understanding of your vehicle's mechanical workings.

Key Specs and Main Parts of the Serpentine Belt System

Before diving into the diagram, let's define the key components:

- Serpentine Belt: A single, long belt made of rubber or a composite material. It's designed to be flexible and durable.

- Crankshaft Pulley (Damper Pulley): This pulley is connected to the crankshaft and drives the serpentine belt. Its primary function is to transmit rotational force from the engine.

- Alternator Pulley: Driven by the serpentine belt, the alternator generates electrical power to charge the battery and power the vehicle's electrical system.

- Power Steering Pump Pulley: Also driven by the belt, this pulley powers the hydraulic pump that provides power assistance to the steering system.

- Air Conditioning Compressor Pulley: The belt drives the compressor, which circulates refrigerant in the AC system, providing cool air.

- Water Pump Pulley: On some 2016 Outlander models (especially those with the 2.4L engine), the water pump is driven by the timing chain inside the engine, not the serpentine belt. On other configurations, the serpentine belt might drive it. Always confirm your specific engine configuration.

- Tensioner Pulley: This spring-loaded pulley maintains the correct tension on the serpentine belt. Proper tension is crucial for optimal performance and belt longevity.

- Idler Pulley: An idler pulley provides a smooth path for the belt to follow, especially when there are complex routing requirements. It has no driven function.

The serpentine belt length is a crucial specification. It must be the correct length for your 2016 Outlander's engine. The correct belt length is usually specified in your owner's manual and is often printed on the old belt itself. Using the wrong length belt can lead to improper tension and component damage.

Understanding Serpentine Belt Diagram Symbols

Serpentine belt diagrams use a variety of symbols and conventions to represent the system accurately. Here's a breakdown:

- Solid Lines: Represent the serpentine belt itself. The thickness of the line doesn't necessarily indicate the belt's actual thickness but indicates its path.

- Circles: Represent pulleys. The size of the circle doesn't necessarily indicate the pulley's actual size.

- Arrows: Indicate the direction of belt rotation around each pulley. This is crucial for understanding the belt's path.

- Text Labels: Label each pulley with its corresponding component (e.g., "Alternator," "Power Steering Pump," "Crankshaft").

- Tensioner Symbol: The tensioner pulley is often represented with a unique symbol, usually a pulley with an arrow indicating its movement range (the spring tension). This is crucial because it is adjustable for belt replacement.

Colors are not usually employed in standard black-and-white diagrams but may be used in some enhanced versions. If colors are used, a legend will usually accompany the diagram explaining their meaning (e.g., red might indicate high-stress areas).

How the Serpentine Belt System Works

The crankshaft pulley, driven by the engine's rotation, provides the initial driving force. The serpentine belt wraps around this pulley and transfers this rotational energy to all other pulleys in the system. The tensioner pulley applies constant pressure to the belt, ensuring it maintains sufficient grip on all the pulleys to prevent slippage. Without proper tension, the belt can slip, leading to reduced performance of the accessories and premature belt wear. Belt slippage is a common cause of squealing noises from the engine bay.

The belt's routing is carefully designed to provide the optimal angle of wrap on each pulley. A larger angle of wrap allows for greater power transfer without slippage. The idler pulley is used to increase the angle of wrap on certain pulleys or to route the belt around obstructions.

Real-World Use: Basic Troubleshooting Tips

The serpentine belt system is prone to several common issues:

- Squealing Noise: This is often caused by a loose belt, a worn belt, or a failing pulley bearing. Inspect the belt for cracks, glazing (a shiny appearance), and missing chunks. Check the tensioner pulley for proper operation. Try spraying a small amount of belt dressing on the belt (use sparingly, as excessive use can attract dirt). If the squealing stops temporarily, the belt is likely the issue.

- Cracked or Worn Belt: Regularly inspect the belt for signs of wear. Cracks, fraying, or missing chunks indicate the belt needs replacement.

- Accessory Failure: If an accessory like the alternator or power steering pump stops working, a broken or slipped serpentine belt is a likely cause.

- Tensioner Failure: A failing tensioner can cause the belt to loosen, leading to squealing, reduced accessory performance, and premature belt wear. Check the tensioner for smooth operation and proper tension.

Using the diagram, you can systematically inspect each component of the system to identify the source of the problem. For example, if you suspect a failing pulley bearing, use a stethoscope (or a long screwdriver placed against your ear – be very careful!) to listen to each pulley while the engine is running. A grinding or rumbling noise indicates a worn bearing.

Safety Considerations

Working on the serpentine belt system can be hazardous. Consider the following safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical components, including the alternator.

- Engine Off and Cool: Never work on the serpentine belt system with the engine running. Allow the engine to cool completely before beginning work.

- Moving Parts: Keep your hands and clothing away from moving parts, especially the serpentine belt and pulleys. The crankshaft pulley in particular can cause serious injury if caught in it when the engine is running.

- Proper Tools: Use the correct tools for the job. A belt tensioner tool is often required to release the tension on the belt for removal and installation.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

The alternator, while not mechanically dangerous when the engine is off, can still store a charge. Disconnecting the battery is essential before working near it to avoid electrical shock.

We have a high-resolution serpentine belt diagram file specifically for the 2016 Mitsubishi Outlander available for download. This diagram will provide a clear visual reference for belt routing and component identification. With this diagram and the knowledge shared in this article, you should be well-equipped to tackle serpentine belt maintenance and troubleshooting on your Outlander.