3 Wire Solenoid Valve Wiring Diagram

Alright, let's dive into the 3-wire solenoid valve wiring diagram. If you're modifying your car, diagnosing a tricky engine problem, or just aiming to understand how actuators are controlled, understanding this diagram is crucial. We're talking about how to interpret the schematic, understand the components, and troubleshoot common issues. We have the full high-resolution diagram available for download – more on that later.

Why This Diagram Matters

Think of the wiring diagram as the blueprint for your electrical system. When dealing with a 3-wire solenoid valve, the diagram tells you exactly which wire does what, where it connects, and how it all integrates with the rest of the vehicle's control system. This is essential for several reasons:

- Diagnosis: Identifying faulty wiring or a malfunctioning solenoid valve becomes much simpler when you can trace the circuit step-by-step.

- Repair: Replacing a damaged connector, wire, or even the valve itself requires knowing the correct connections.

- Modification: Adding performance parts like aftermarket boost controllers or electronic exhaust cutouts frequently involves integrating with existing solenoid valves. Understanding the wiring prevents costly mistakes and ensures proper function.

- Education: Even if you don't plan on wrenching on your car today, understanding these systems increases your overall automotive knowledge and can empower you to make informed decisions about repairs and upgrades.

Key Specs and Main Parts

Before we jump into the diagram itself, let's define some essential terms and components:

- Solenoid Valve: An electromechanical valve controlled by an electric current. When energized, the solenoid creates a magnetic field that moves a plunger, opening or closing the valve.

- 3-Wire Configuration: This specific configuration usually comprises a power wire, a ground wire, and a control wire. The control wire is the key; it's connected to a control unit (like an ECU or PCM) that regulates the valve's operation.

- ECU/PCM (Engine Control Unit/Powertrain Control Module): The brain of the engine management system. It receives sensor data and controls various actuators, including solenoid valves.

- Relay: An electrically operated switch. Often, a relay is used to control the power supplied to the solenoid valve, allowing a low-current signal from the ECU to switch a high-current circuit.

- Fuse: A safety device that protects the circuit from overcurrent. If the current draw exceeds the fuse's rating, the fuse blows, interrupting the circuit and preventing damage.

- Connector: The physical interface where wires are joined. These can be subject to corrosion and damage, leading to poor connections.

Symbols – Decoding the Diagram

The wiring diagram uses standardized symbols to represent components and connections. Here's a breakdown of common symbols you'll encounter:

- Solid Lines: Represent wires. Thicker lines typically indicate power wires carrying higher current.

- Dotted/Dashed Lines: Indicate shielded wires or connections to ground.

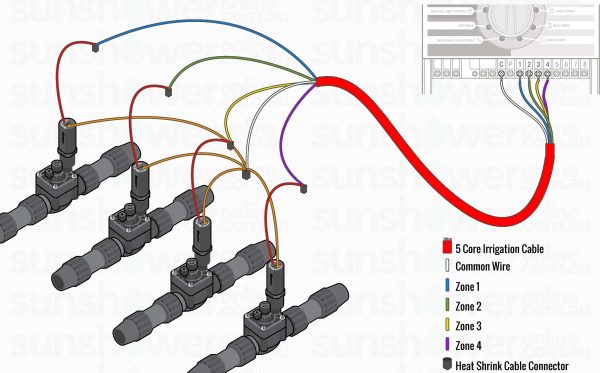

- Colors: Wires are color-coded for identification. Common colors include red (power), black (ground), and various other colors for signal wires. The diagram key will define each color's function.

- Solenoid Valve Symbol: Often depicted as a rectangle with a coil symbol inside, along with the valve symbol itself (usually a circle with arrows indicating flow direction).

- Ground Symbol: Usually represented as a series of downward-pointing lines or a triangle pointing downwards.

- Relay Symbol: A square with a coil symbol inside, along with switch contacts.

- Fuse Symbol: A squiggly line enclosed in a rectangle or a simple rectangle with the amperage rating indicated.

Understanding these symbols allows you to trace the circuit on the diagram, identifying the components and their connections.

How It Works

Let's break down how a typical 3-wire solenoid valve circuit operates:

- Power Supply: The solenoid valve receives power, usually 12V, from the vehicle's electrical system. This power is often supplied through a fuse and potentially a relay. The power wire is typically connected directly to the positive terminal of the battery, sometimes via the ignition switch.

- Ground Connection: A dedicated ground wire ensures a complete circuit. This wire is connected to the vehicle's chassis or directly to the negative terminal of the battery. A good, clean ground connection is vital for proper operation.

- Control Signal: The ECU/PCM sends a signal to the control wire. This signal is typically a pulse-width modulated (PWM) signal, meaning the ECU rapidly switches the ground connection on and off. The *duty cycle* of this PWM signal – the percentage of time the signal is "on" – determines the amount of current flowing through the solenoid and, consequently, the valve's position.

- Valve Activation: When the ECU activates the control signal, current flows through the solenoid coil, creating a magnetic field. This magnetic field pulls the valve's plunger, opening or closing the valve. The specific function depends on the valve's design (normally open or normally closed).

Essentially, the ECU modulates the current flow through the solenoid to precisely control the valve's operation. This control is critical for various functions, such as controlling boost pressure in a turbocharger, regulating fuel pressure, or managing exhaust gas recirculation (EGR).

Real-World Use – Basic Troubleshooting Tips

Here are some common troubleshooting steps you can take using the wiring diagram:

- No Valve Operation: If the solenoid valve isn't working, start by checking the fuse. A blown fuse indicates a short circuit or overcurrent. Next, verify the power and ground connections using a multimeter. Ensure you have 12V at the power wire (with the ignition on) and a good ground connection. Finally, check the control wire for a PWM signal from the ECU. A scan tool can often display the duty cycle being sent by the ECU.

- Intermittent Operation: Intermittent problems can be caused by loose connections, corroded terminals, or a failing solenoid valve. Carefully inspect the wiring harness and connectors for damage. Clean and re-seat any suspect connections. You can also try tapping on the solenoid valve while it's energized to see if it temporarily restores operation.

- Erratic Readings: If the valve is operating erratically, it could be due to a faulty solenoid valve, a wiring problem, or an issue with the ECU. Start by ruling out wiring issues before suspecting the ECU. Replace the solenoid valve as a next step.

Important Tools: A multimeter is essential for measuring voltage, current, and resistance. A scan tool allows you to read diagnostic trouble codes (DTCs) and monitor sensor data, including the ECU's control signal to the solenoid valve. A wiring test light can also be useful for quickly checking power and ground connections.

Safety – Highlight Risky Components

Working with automotive electrical systems can be dangerous. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical components. This prevents accidental short circuits.

- Identify High-Current Circuits: Be especially careful when working with high-current circuits, such as the power supply to the solenoid valve. A short circuit in these circuits can cause sparks, fires, and even explosions.

- Use Proper Tools: Use insulated tools and wear safety glasses to protect yourself from electrical shock and flying debris.

- Don't Modify Wiring Indiscriminately: Avoid cutting or splicing wires unless you're absolutely sure of what you're doing. Incorrect wiring can damage the ECU and other components.

- Be Aware of Capacitors: Some electronic components, like those in the ECU, can store electrical charge even after the battery is disconnected. Allow sufficient time for these components to discharge before handling them.

Disclaimer: Automotive electrical systems are complex. If you're not comfortable working with electricity, it's best to consult a qualified mechanic.

Hopefully, this article provided a solid understanding of the 3-wire solenoid valve wiring diagram. Remember, a clear understanding of the diagram is the first step toward successful diagnosis and repair. As promised, we have the full high-resolution wiring diagram available for download, which provides even more detail and specifics relevant to different vehicle models. Contact us for the link.