3.0 V6 Engine 3.0 Ford Ranger Vacuum Hose Diagram

Alright, let's dive into the vacuum hose diagram for the 3.0 V6 engine found in Ford Rangers. This isn't the most glamorous part of your truck, but understanding its intricate network is crucial for maintaining optimal performance, diagnosing problems, and even tackling some modifications. Think of it as the circulatory system of your engine's air management – get a blockage or leak, and things go south fast.

Purpose of the Vacuum Hose Diagram

Why bother with this diagram? Simple. It's your roadmap to the vacuum system. The vacuum system, in turn, is responsible for controlling a whole host of engine functions. Without a correct and leak-free vacuum system, you'll be chasing symptoms like:

- Poor fuel economy: Leaks can mess with the air/fuel ratio, leading to wasted gas.

- Rough idling: The engine struggles to maintain a smooth idle due to incorrect air intake.

- Engine misfires: Improper vacuum can affect ignition timing and fuel delivery.

- Emissions failures: Vacuum leaks directly impact emissions control systems.

- Check Engine Light (CEL): A vacuum leak is a common trigger for diagnostic trouble codes (DTCs) and the dreaded CEL.

This diagram allows you to:

- Diagnose vacuum leaks: Pinpoint the source of a leak by tracing hoses and connections.

- Replace hoses correctly: Ensure you're routing new hoses exactly as the factory intended.

- Understand engine control systems: See how different components are interconnected and work together.

- Perform modifications: Some modifications require manipulating vacuum lines. Knowing the original setup is critical.

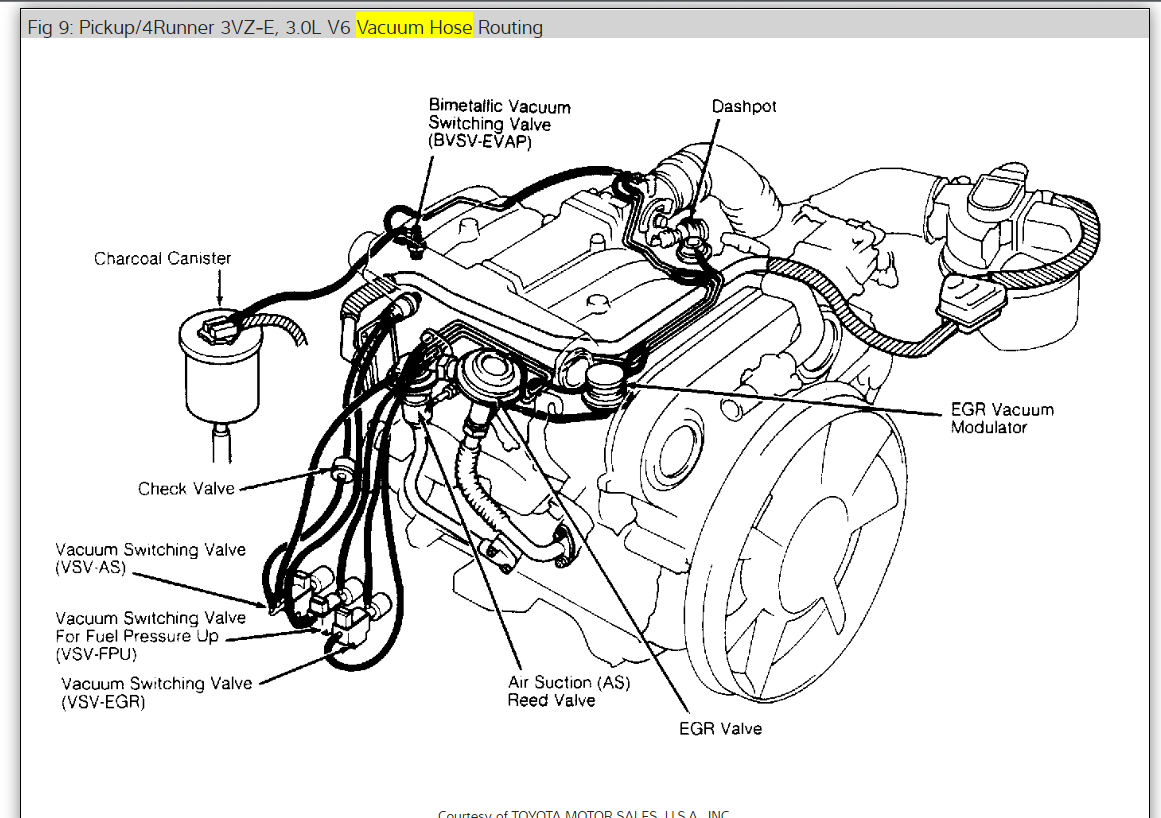

Key Specs and Main Parts of the 3.0 V6 Vacuum System

The 3.0 V6 Vulcan engine used in Ford Rangers (primarily from the early 1990s to the mid-2000s) has a fairly complex vacuum system. Here are the key components you'll find on the diagram and on your engine:

- Intake Manifold: The central hub for vacuum. Manifold vacuum is the base from which all other vacuum is derived. It's the vacuum created by the pistons moving down on their intake stroke.

- Vacuum Reservoir (Canister): A storage tank for vacuum. This ensures a consistent vacuum supply to various components, even under changing engine loads. Often a black plastic sphere or cylinder.

- PCV Valve (Positive Crankcase Ventilation Valve): Recirculates crankcase gases back into the intake manifold, reducing emissions and preventing pressure buildup in the crankcase. A common source of leaks if the valve or its hoses are cracked or brittle.

- EGR Valve (Exhaust Gas Recirculation Valve): Reduces NOx emissions by recirculating a portion of the exhaust gas back into the intake manifold. Controlled by vacuum.

- EVAP System (Evaporative Emission Control System): Prevents fuel vapors from escaping into the atmosphere. Uses vacuum to purge the charcoal canister.

- Brake Booster: Provides vacuum-assisted braking, making it easier to stop. A major vacuum leak here is a serious safety hazard!

- HVAC Controls: Vacuum actuators control the blend doors and mode doors in your heating, ventilation, and air conditioning system. Leaks here will cause issues with vent selection.

- Vacuum Lines/Hoses: The connectors of the entire system. Made from rubber or plastic and are prone to cracking and dry rotting.

- Check Valves: One-way valves that ensure vacuum flows in the correct direction.

- Vacuum Solenoids: Electrically controlled valves that switch vacuum on and off to various components.

Understanding the Symbols on the Vacuum Hose Diagram

Deciphering the diagram is key to using it effectively. Here's a breakdown of common symbols:

- Solid Lines: Usually represent vacuum hoses. The thickness of the line *might* indicate the hose diameter, but don't rely on this.

- Dotted Lines: Often represent electrical wiring associated with vacuum solenoids or sensors.

- Arrows: Indicate the direction of airflow (vacuum).

- Circles or Squares with Letters/Abbreviations: These represent the components listed above (PCV, EGR, EVAP, etc.). The diagram will have a legend to explain these abbreviations.

- Color Coding: Some diagrams use color coding to differentiate between different vacuum lines. The legend will explain the color scheme. For example, a blue line might represent a vacuum source, while a red line might represent a vacuum signal. However, don't rely on color alone, as the hoses themselves fade and discolor over time.

- Connectors and Fittings: Represented by small symbols showing how hoses connect to components or to each other.

Important: The specific symbols used can vary slightly depending on the year and model of your Ranger. Always refer to the specific diagram for your vehicle.

How It Works: The Vacuum System in Action

The engine creates a vacuum (negative pressure) inside the intake manifold. This vacuum is then distributed through the network of hoses to various components. Think of it like this: the intake manifold is the vacuum pump, and the hoses are the pipes carrying the vacuum to where it's needed.

For example, let's look at the EGR system. The EGR valve needs to open to allow exhaust gas to recirculate. The engine control unit (ECU), or Powertrain Control Module (PCM), determines when the EGR valve should open. It then activates a vacuum solenoid, which allows manifold vacuum to reach the EGR valve diaphragm. The vacuum pulls the diaphragm, opening the EGR valve and allowing exhaust gas to flow into the intake manifold.

Similarly, the EVAP system uses vacuum to purge fuel vapors from the charcoal canister. The PCV system uses manifold vacuum to draw crankcase gases back into the intake. Even your brakes rely on vacuum for power assist! If your brakes ever feel hard to press, a leak in the brake booster vacuum line could be to blame.

Real-World Use: Basic Troubleshooting Tips

The vacuum hose diagram becomes invaluable when troubleshooting vacuum-related issues. Here’s a basic approach:

- Identify the Symptoms: What's the problem? Rough idle? Poor fuel economy? Knowing the symptoms narrows down the possible culprits.

- Visually Inspect the Hoses: Start with a thorough visual inspection. Look for cracked, brittle, or disconnected hoses. Pay close attention to hoses near the engine, as they are exposed to heat and are more likely to fail.

- Listen for Hissing: A hissing sound is a dead giveaway for a vacuum leak. Use a length of hose as a stethoscope to pinpoint the location of the hiss.

- Use a Vacuum Gauge: A vacuum gauge connected to a manifold vacuum source can tell you if the overall vacuum is within the normal range. Low vacuum indicates a significant leak.

- Smoke Test: A smoke test is the most effective way to find vacuum leaks. A smoke machine introduces smoke into the vacuum system. The smoke will escape from any leaks, making them easy to spot.

- Use Carb Cleaner/Starting Fluid (Carefully!): This is a risky method and should be done with extreme caution. Spray small amounts of carb cleaner or starting fluid around potential leak areas (hose connections, intake manifold gaskets). If the engine RPM changes, you've likely found a leak. **Do not spray near hot exhaust components! Fire hazard is very high!** Ensure adequate ventilation and have a fire extinguisher nearby.

- Consult the Diagram: Once you suspect a specific hose or component, refer to the diagram to confirm its routing and function.

Safety Considerations

Working on the vacuum system is generally safe, but some components require extra caution:

- Brake Booster Hose: A leak in the brake booster hose can significantly reduce braking power. Inspect this hose regularly and replace it immediately if it shows any signs of damage.

- Fuel Lines: Some vacuum lines run near fuel lines. Be extremely careful when working in these areas to avoid damaging fuel lines or creating a spark.

- Hot Engine Components: The exhaust manifold and other engine components can be extremely hot. Allow the engine to cool down completely before working on the vacuum system.

- Carb Cleaner/Starting Fluid: As mentioned above, these are flammable and should be used with extreme caution and proper ventilation.

Always disconnect the negative battery cable before working on any electrical components related to the vacuum system.

This article provides a comprehensive overview of the 3.0 V6 Ford Ranger vacuum hose diagram. Keep in mind that the specific layout may vary slightly depending on the year and model of your truck. Remember to consult the diagram specific to *your* Ranger for the most accurate information. We have access to these diagrams and you can download a PDF version by contacting us through the form on the bottom of the page.