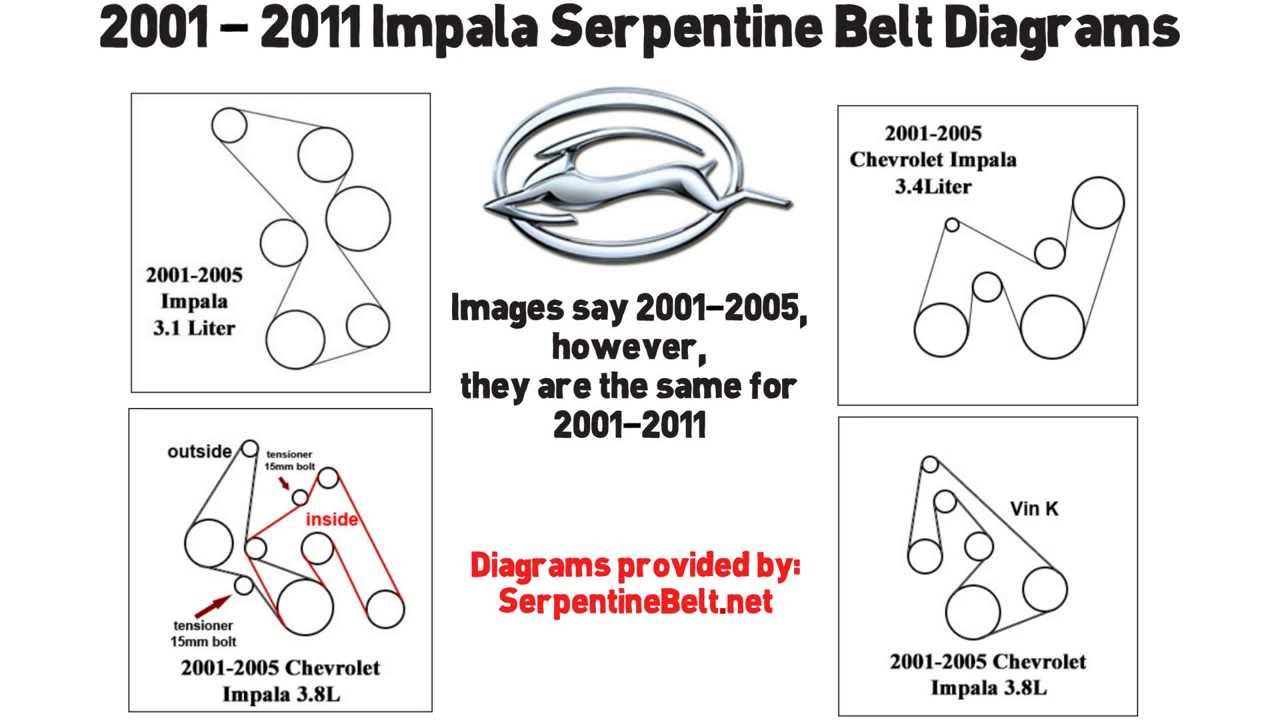

3.5 L 2008 Chevy Impala 3.5 Serpentine Belt Diagram

Alright, let's dive into the serpentine belt system on your 2008 Chevy Impala with the 3.5L engine. This guide is designed for the seasoned DIYer who wants to understand the ins and outs of this critical engine component. We'll cover everything from why the serpentine belt diagram is crucial to real-world troubleshooting tips.

Purpose of the Serpentine Belt Diagram

Why bother with a serpentine belt diagram? Simple: it's your roadmap to a properly functioning accessory drive system. The serpentine belt, sometimes called an accessory belt, is responsible for powering several crucial components of your Impala. These include:

- Alternator: Charges your battery and powers electrical systems.

- Power Steering Pump: Provides hydraulic assistance for steering.

- Air Conditioning Compressor: Cools the cabin.

- Water Pump: Circulates coolant to prevent overheating (sometimes driven by the timing belt, but in this case, by the serpentine belt).

A correct serpentine belt routing ensures that all these components receive the necessary power. The diagram is essential for:

- Belt Replacement: Ensuring the new belt is routed correctly. Incorrect routing can lead to component failure or even engine damage.

- Troubleshooting: Identifying if a belt has slipped or is routed incorrectly.

- Understanding System Layout: Grasping how the various components are interconnected.

- General Maintenance: Checking belt condition and tension.

Key Specs and Main Parts

Let's break down the key components of the serpentine belt system on your 2008 Impala 3.5L:

- Serpentine Belt: The heart of the system, made of reinforced rubber. Look for signs of wear, cracks, or fraying. The specific length and type of belt is crucial for proper tensioning and operation. Always use a belt that matches the OEM (Original Equipment Manufacturer) specification for your vehicle.

- Crankshaft Pulley (Harmonic Balancer): This pulley, attached to the crankshaft, is the driving force behind the entire system. It transfers the engine's rotational energy to the belt.

- Alternator Pulley: Driven by the belt, it rotates the alternator, generating electricity.

- Power Steering Pump Pulley: Driven by the belt, it rotates the power steering pump, providing hydraulic assist.

- Air Conditioning Compressor Pulley: Driven by the belt, it rotates the AC compressor, responsible for cooling.

- Water Pump Pulley: Driven by the belt, this pulley rotates the water pump, circulating coolant.

- Tensioner Pulley: This spring-loaded pulley maintains the correct tension on the belt. This is absolutely crucial for proper operation. A worn tensioner can cause belt slippage, noise, and premature belt wear.

- Idler Pulley: A smooth pulley used to guide the belt around other components and prevent interference. Not all systems have idler pulleys, but your Impala might.

Symbols on the Serpentine Belt Diagram

Understanding the symbols used on the diagram is key to interpreting it correctly. Here's a breakdown of common symbols:

- Solid Lines: Typically represent the path of the front of the serpentine belt.

- Dotted Lines: Often indicate the path of the back of the serpentine belt. This usually means the belt is making contact with a smooth idler or tensioner pulley, or running along the back side of a pulley, utilizing its smooth surface.

- Arrows: Show the direction of belt rotation. Pay close attention to these!

- Component Icons: Simplified representations of the alternator, power steering pump, AC compressor, water pump, crankshaft pulley, tensioner, and idler pulleys. These icons are usually labeled or accompanied by abbreviations (ALT, P/S, A/C, W/P, CRANK, TENS, IDLER).

- Color Coding (Less Common): Some diagrams might use color to differentiate between the front and back of the belt, or to highlight specific components.

How It Works

The serpentine belt system is elegantly simple in concept. The crankshaft pulley, driven by the engine, provides the rotational force. This force is transferred to the serpentine belt, which wraps around the various accessory pulleys. The tensioner pulley ensures that the belt remains taut, preventing slippage and maximizing power transfer. The correct routing of the belt, as indicated by the diagram, ensures that each component rotates in the correct direction and receives the necessary power.

The tensioner is critical. It's usually a spring-loaded arm that pivots. The tensioner maintains consistent belt tension despite fluctuations in engine speed and temperature, which can cause the belt to expand or contract. A failing tensioner can cause the belt to vibrate excessively, make noise (squealing or chirping), and eventually lead to belt failure and component damage.

Real-World Use: Basic Troubleshooting Tips

Here are some common issues you might encounter and how the serpentine belt diagram can help you diagnose them:

- Squealing Noise: Often indicates a loose or worn belt. Check the belt tension and condition. The diagram will help you ensure the belt is routed correctly and that the tensioner is functioning properly. If the belt is old or cracked, replace it. A glazing (shiny appearance) on the belt ribs can also cause squealing.

- Chirping Noise: Can be caused by a misaligned pulley or a worn idler pulley. Use the diagram to visually inspect the pulley alignment. Check for wobble or roughness in the idler pulley bearings.

- Loss of Power Steering or Air Conditioning: Indicates a slipped or broken belt. Immediately stop the vehicle and inspect the belt. The diagram will help you identify the correct routing for a replacement belt.

- Battery Not Charging: Could be a faulty alternator, but also a slipping serpentine belt. Ensure the belt is properly tensioned and that the alternator pulley is rotating when the engine is running. The diagram will show you the alternator's position in the system.

When troubleshooting, remember to always disconnect the negative battery cable before working on the system to prevent accidental electrical shock. Also, be mindful of hot engine components.

Safety Considerations

Working on the serpentine belt system can be dangerous if you're not careful. Here are some crucial safety precautions:

- Rotating Components: The engine's crankshaft pulley and all the accessory pulleys are extremely dangerous when the engine is running. Keep your hands, clothing, and tools clear of these components.

- Hot Engine: Allow the engine to cool completely before working on the system. Exhaust manifolds and other components can be extremely hot and cause severe burns.

- Spring-Loaded Tensioner: The tensioner pulley is under significant spring pressure. Use the correct tool (usually a serpentine belt tool) to relieve the tension before removing or installing the belt. Never attempt to release the tensioner manually, as this could result in serious injury.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Disconnect Battery: Disconnect the negative battery cable before working on the system to prevent electrical shock.

Finally, if you're not comfortable working on the serpentine belt system, don't hesitate to consult a qualified mechanic. Improper installation or repair can lead to component failure or even engine damage.

With this detailed guide and the serpentine belt diagram in hand, you should be well-equipped to understand, maintain, and troubleshoot the serpentine belt system on your 2008 Chevy Impala 3.5L. Remember safety first, and always double-check your work.