3.5 L 2011 Chevy Impala 3.5 Serpentine Belt Diagram

Alright, let's dive into the serpentine belt system on your 2011 Chevy Impala with the 3.5L engine. This article serves as a comprehensive guide to understanding the serpentine belt diagram, its purpose, and how to effectively use it for maintenance and repairs. Think of this as your trusted mechanic explaining the intricacies of the system in a way that's both technically accurate and easy to grasp.

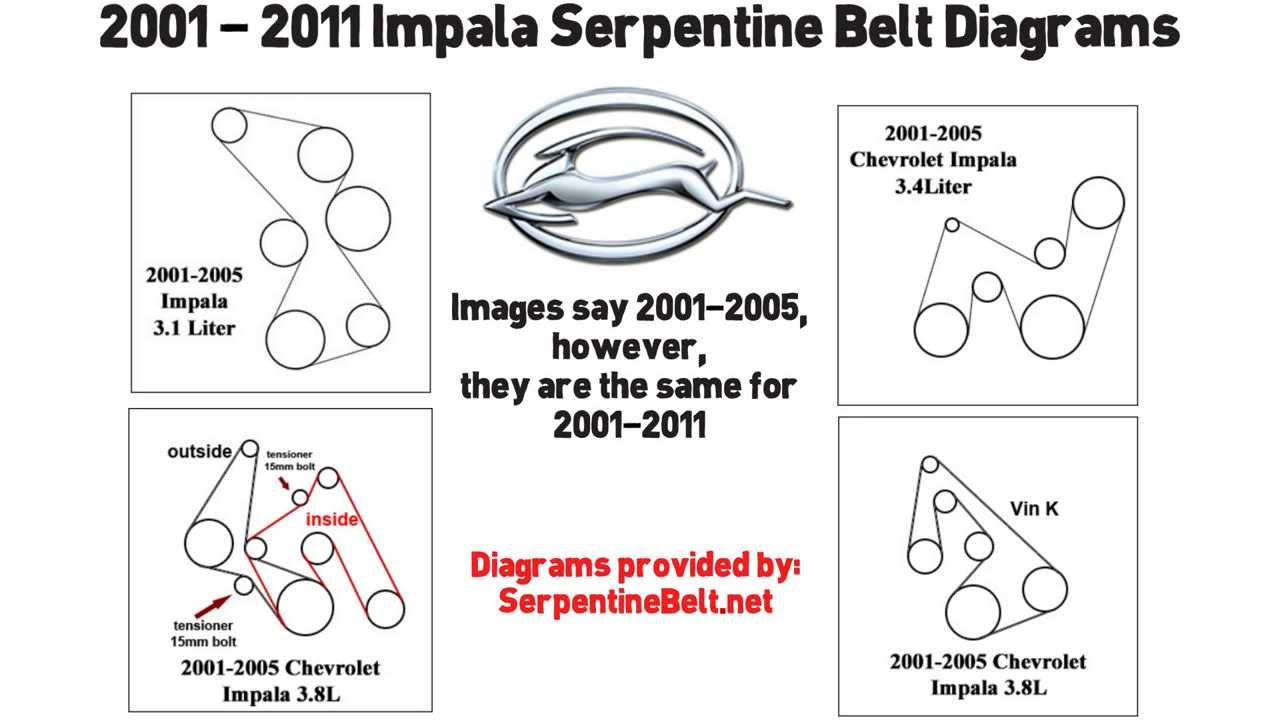

Purpose of the Serpentine Belt Diagram

The serpentine belt diagram isn't just a pretty picture; it's your roadmap for maintaining the accessory drive system in your Impala. Its main purposes include:

- Accurate Belt Routing: The most crucial function is showing you the correct path for the serpentine belt. An incorrectly routed belt can cause serious damage to components, like a seized alternator or a blown power steering pump.

- Troubleshooting: When your belt breaks, snaps, or starts squealing, the diagram helps you quickly identify the components driven by the belt and diagnose potential issues.

- Component Identification: It allows you to visually identify each pulley and the component it's attached to (alternator, power steering pump, AC compressor, etc.). This is essential for replacing worn-out parts.

- Facilitating Repairs: Whether you're replacing the belt itself, a pulley, or an entire accessory component, the diagram ensures you have the correct routing for reassembly.

- General Understanding: Even if you're not actively repairing anything, studying the diagram gives you a better understanding of how your engine's accessories are powered.

Key Specs and Main Parts (2011 Chevy Impala 3.5L)

Before we delve into the diagram, let's cover the basics. The 2011 Chevy Impala with the 3.5L engine typically uses a single serpentine belt to drive the following accessories:

- Crankshaft Pulley (Harmonic Balancer): This is the engine's main drive pulley, connected directly to the crankshaft. It transfers the engine's rotational energy to the serpentine belt. The harmonic balancer part of the pulley also helps dampen engine vibrations.

- Alternator: The alternator charges your car's battery and powers the electrical system.

- Power Steering Pump: Provides hydraulic pressure to assist with steering, making it easier to turn the wheel.

- Air Conditioning (AC) Compressor: Compresses refrigerant to cool the cabin.

- Water Pump: Circulates coolant through the engine to regulate temperature. On some Impala configurations, the water pump may be driven by the serpentine belt. Confirm this on your specific vehicle, as some older models may use a separate belt.

- Tensioner Pulley: This spring-loaded pulley applies tension to the serpentine belt, ensuring it remains tight and doesn't slip. A failing tensioner is a common cause of belt squeal.

- Idler Pulley(s): Smooth, non-driven pulleys that guide the belt and optimize its routing. They change the belt's direction and wrap angle around other pulleys to improve grip and prevent slippage.

Belt Length: The specific length of the serpentine belt can vary slightly depending on the exact vehicle configuration (with or without specific options). It's always best to consult your vehicle's owner's manual or a parts catalog for the correct part number. Typically, you will find a part number stamped on the belt itself that can be cross-referenced.

Understanding the Diagram Symbols

A serpentine belt diagram uses a visual language to convey information. Here's a breakdown of common symbols:

- Solid Lines: Represent the path of the serpentine belt itself. Following the line shows you the correct routing around the pulleys.

- Dashed Lines: Usually indicate the *back* side of the belt, meaning the smooth side of the belt is in contact with the pulley. This is important to know for correct routing.

- Circles or Rounded Shapes: These represent pulleys. They may have labels indicating which component they belong to (ALT for alternator, P/S for power steering, A/C for air conditioning, etc.).

- Arrows: Indicate the direction of belt travel. This helps you visualize how the belt moves around the pulleys.

- Text Labels: Provide additional information, such as component names, belt specifications, or torque specifications for fasteners.

- Tensioner Symbol: The tensioner pulley is often depicted with a spring symbol indicating its spring-loaded function. Some diagrams also use an arrow to show the direction the tensioner arm moves when releasing tension.

Colors are rarely used on diagrams, but if they are, they might be used to highlight a specific section of the belt path or to differentiate between the front and back sides of the belt. However, color is not a standard feature.

How the Serpentine Belt System Works

The serpentine belt system is a relatively simple, yet critical, part of your engine. The crankshaft pulley, driven directly by the engine, is the heart of the system. As the engine rotates, the crankshaft pulley spins the serpentine belt. The belt, in turn, wraps around and drives all the other pulleys connected to the accessory components (alternator, power steering pump, AC compressor, water pump). The tensioner pulley maintains constant tension on the belt, preventing slippage. The idler pulleys further optimize the belt’s contact and path, ensuring efficient power transfer to each component.

Without a properly functioning serpentine belt system, your car won't run properly. A broken belt will immediately disable the alternator, leading to a dead battery. It will also disable power steering, making the car difficult to steer, and will stop the AC compressor from working, resulting in no air conditioning. If the water pump is driven by the serpentine belt, the engine can overheat very quickly, potentially causing severe damage.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems you might encounter with your serpentine belt system and how the diagram can help you troubleshoot them:

- Squealing Noise: A squealing noise, especially when the engine is first started or under heavy load, often indicates a slipping belt. Using the diagram, inspect the belt for cracks, glazing, or missing chunks. Also, check the tensioner pulley for proper operation. If the tensioner arm is bouncing excessively, it may need to be replaced.

- Belt Breakage: A broken belt is often the result of a worn-out belt, a seized component, or a misaligned pulley. After replacing the belt, carefully inspect each pulley and accessory component to ensure it rotates freely. Use the diagram to verify correct alignment. Misalignment will quickly destroy a new belt.

- Power Steering or AC Failure: If you suddenly lose power steering or air conditioning, check the serpentine belt immediately. A broken or slipping belt is a likely cause. The diagram will confirm whether these components are indeed driven by the belt.

- Battery Not Charging: If your battery is not charging, the alternator may not be spinning due to a problem with the serpentine belt. Inspect the belt and tensioner pulley. Use a multimeter to test the alternator’s output once you have verified belt integrity.

Safety Precautions

Working on the serpentine belt system can be dangerous if you're not careful. Here are some critical safety precautions:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components, including the alternator. This prevents accidental shorts.

- Engine Off and Cool: Never work on the serpentine belt system while the engine is running or hot. Allow the engine to cool completely before starting any work.

- Keep Fingers Clear: Be extremely careful when working around the pulleys and belt. A spinning belt can cause serious injury.

- Use the Correct Tools: Use the correct tools for the job, including a serpentine belt tool for releasing tension on the tensioner pulley.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

- Be Aware of Hot Surfaces: Exhaust manifolds and other engine components can remain hot for a considerable time after the engine is turned off. Be mindful of these potential burn hazards.

The area around the crankshaft pulley is particularly risky. The engine can be accidentally cranked while the belt is off causing serious injury if your fingers are in the way. Be extra cautious when working in this area.

We have a detailed, downloadable serpentine belt diagram for your 2011 Chevy Impala 3.5L engine. This diagram will provide you with the precise routing and component identification you need for successful maintenance and repairs. Remember, if you're unsure about any aspect of the serpentine belt system, it's always best to consult a qualified mechanic.