3.6 Liter 2011 Gmc Acadia 3.6 Serpentine Belt Diagram

Welcome! You're here to understand the serpentine belt system on your 2011 GMC Acadia with the 3.6L engine. This article provides a detailed technical breakdown of the serpentine belt diagram, its components, operation, and practical troubleshooting advice. Knowing how this system functions is crucial for maintenance, repairs, and even just understanding the health of your engine. Having this knowledge empowers you to confidently tackle DIY projects or have informed discussions with your mechanic.

Purpose of Understanding the Serpentine Belt Diagram

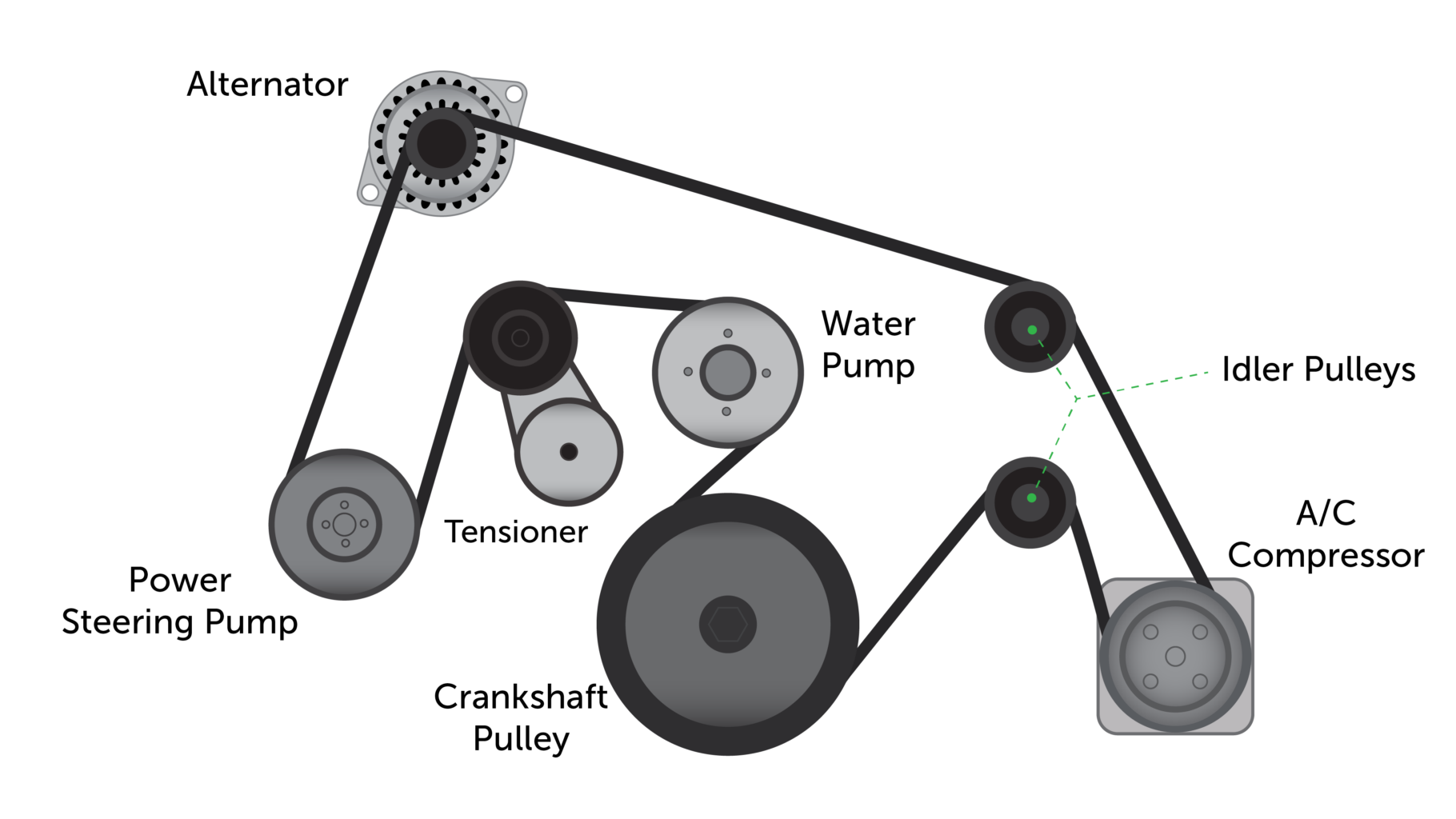

The serpentine belt diagram is your roadmap to understanding how engine accessories are powered. Its primary purpose is to illustrate the routing path of the serpentine belt, which is responsible for driving several critical components. Without a clear understanding of the diagram, tasks like replacing the belt, diagnosing accessory failures, or even just inspecting the system become significantly more complex and prone to error. Here are the key reasons why grasping the diagram's importance matters:

- Repair and Replacement: Accurately routing a new serpentine belt is paramount. An incorrectly routed belt can damage accessories, cause belt slippage (resulting in reduced performance of systems like the power steering and AC), or even lead to catastrophic engine damage.

- Diagnosis: The diagram helps in identifying potential issues within the system. For instance, if you notice a squealing noise, the diagram can assist in isolating the likely source, whether it's a failing idler pulley or an overstressed accessory.

- Preventative Maintenance: Regularly inspecting the belt and its associated components is crucial for preventing breakdowns. Knowing the belt's path allows for a thorough visual inspection, checking for signs of wear, cracks, or misalignment.

- Understanding Engine Operation: A deeper knowledge of the serpentine belt system contributes to a better overall understanding of how your engine functions.

Key Specs and Main Parts (2011 GMC Acadia 3.6L)

The 2011 GMC Acadia with the 3.6L engine utilizes a single serpentine belt to drive multiple engine accessories. Understanding the components involved is essential for interpreting the diagram.

Main Components:

- Crankshaft Pulley (or Damper): This pulley is connected directly to the crankshaft and provides the rotational force to drive the serpentine belt. It's a critical component that also helps dampen engine vibrations.

- Alternator Pulley: Driven by the serpentine belt, the alternator generates electricity to power the vehicle's electrical system and charge the battery.

- Power Steering Pump Pulley: This pulley drives the power steering pump, providing hydraulic assistance for steering.

- Air Conditioning (A/C) Compressor Pulley: The A/C compressor is responsible for cooling the cabin air. Its pulley is driven by the serpentine belt.

- Water Pump Pulley: This pulley drives the water pump, which circulates coolant throughout the engine to regulate its temperature. Overheating is a serious risk if the water pump fails.

- Idler Pulley(s): These are smooth pulleys that guide and tension the serpentine belt, ensuring proper wrap around other pulleys and preventing belt slippage. They typically lack grooves.

- Tensioner Pulley: This pulley is spring-loaded and automatically maintains the correct tension on the serpentine belt. A properly functioning tensioner is crucial for belt longevity and preventing accessory damage.

- Serpentine Belt: The actual belt itself, typically made of rubber reinforced with cords, transmitting power from the crankshaft to the various accessories.

Key Specs:

While the specific length of the belt can vary slightly based on manufacturer, it is crucial to get the proper belt size for your 2011 GMC Acadia with the 3.6L engine. Consult your owner's manual or a reputable auto parts store for the correct belt length. Using the wrong length can result in incorrect tension and premature wear or failure.

Understanding the Symbols in the Serpentine Belt Diagram

Serpentine belt diagrams use standardized symbols to convey information efficiently. Understanding these symbols is crucial for correctly interpreting the diagram.

- Solid Lines: Represent the path of the serpentine belt itself. The thickness of the line can sometimes indicate the belt's width (though this is less common).

- Arrows: Indicate the direction of rotation for each pulley. Pay close attention to these arrows when routing the belt to ensure proper accessory function.

- Circles: Represent the pulleys themselves. The presence or absence of grooves within the circle indicates whether the pulley is grooved (like the crankshaft, alternator, AC compressor, power steering, and water pump) or smooth (like idler pulleys).

- Squares or Rectangles (occasionally): May represent the tensioner assembly, though often the tensioner is shown simply as a pulley with an arrow indicating the direction of its spring-loaded movement.

- Acronyms: Abbreviations are used to label each pulley, such as ALT for alternator, P/S for power steering, A/C for air conditioning, WP for water pump, CRK for crankshaft, and IDL for idler.

- Dashed Lines (Rare): In some diagrams, dashed lines might represent the belt's path on the backside of a pulley. This is less common but can be important to note for routing the belt correctly.

How the Serpentine Belt System Works

The serpentine belt system operates on a simple principle: the rotational force of the engine's crankshaft is transferred to various accessories via a continuous belt. The crankshaft pulley, driven by the engine, spins the serpentine belt. This belt, in turn, wraps around the pulleys of the alternator, power steering pump, A/C compressor, and water pump, causing them to rotate and perform their respective functions. The tensioner pulley maintains constant tension on the belt, preventing slippage and ensuring efficient power transfer.

The belt's routing is specifically designed to maximize contact with each pulley, ensuring adequate grip and preventing premature wear. The idler pulleys guide the belt along the correct path, optimizing the wrap angle on other pulleys. Without proper tension and routing, the accessories will not operate efficiently, leading to reduced performance, overheating, and potential component failure.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems you might encounter with your serpentine belt system and how to address them using your understanding of the diagram:

- Squealing Noise: This is often caused by a loose or worn serpentine belt. Check the tensioner pulley to ensure it's functioning correctly. Inspect the belt for cracks, glazing, or fraying. Replace the belt if necessary. Misalignment of a pulley can also cause squealing; use a straight edge to ensure all pulleys are in alignment.

- Battery Not Charging: If your battery isn't charging, the alternator might not be spinning correctly. Verify that the serpentine belt is properly routed and tensioned. Check the alternator pulley for damage or slippage.

- Power Steering Failure: If you experience difficulty steering, the power steering pump might not be receiving adequate power. Inspect the serpentine belt and power steering pump pulley.

- Overheating: A failing water pump can lead to engine overheating. Ensure the serpentine belt is driving the water pump pulley correctly. Check the water pump for leaks or unusual noises.

- A/C Not Cooling: If the A/C compressor isn't engaging, the serpentine belt might be slipping or the compressor itself might be failing. Inspect the belt and compressor pulley.

Safety Considerations

Working on the serpentine belt system involves potential hazards. Always disconnect the negative battery cable before working on the system to prevent electrical shocks. Never put your hands near a moving serpentine belt or pulleys. Be extremely cautious when working near the engine, as components can be hot. Use appropriate tools and wear safety glasses to protect your eyes. When removing the serpentine belt, relieve the tension on the tensioner pulley using a suitable tool (usually a wrench or socket). Be aware that the tensioner spring is under considerable force, and uncontrolled release can cause injury. Double-check the belt routing before starting the engine to avoid damage to the accessories or belt.

Pay special attention to the alternator. While the engine is running, the alternator is producing high voltage. Avoid touching any exposed terminals or wiring related to the alternator while the engine is running.

Remember that improper maintenance or repair of the serpentine belt system can lead to serious engine damage or personal injury. If you're not comfortable performing these tasks yourself, seek the assistance of a qualified mechanic.

We have a downloadable version of the 2011 GMC Acadia 3.6L serpentine belt diagram available. This detailed diagram will be a valuable resource for your future maintenance and repair endeavors.