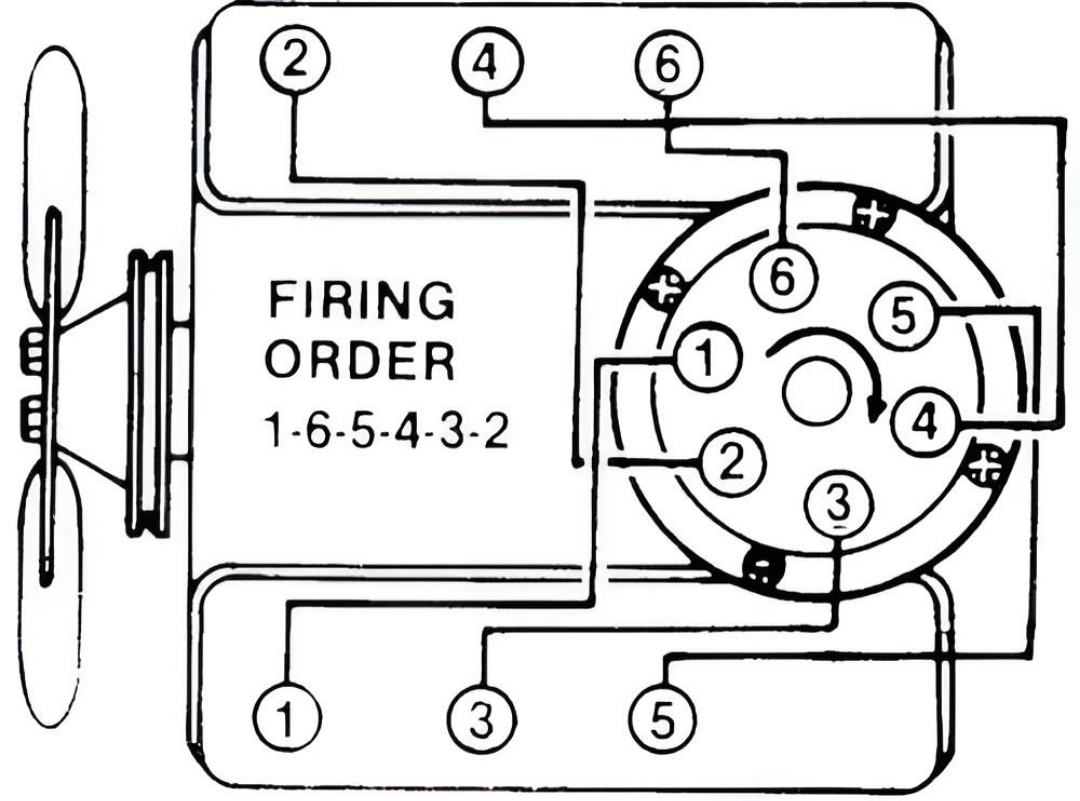

4.3 Firing Order Distributor Diagram

Alright, let's dive into firing order distributor diagrams. If you're tackling engine work, modifications, or just want a deeper understanding of how your engine ticks, understanding this diagram is absolutely crucial. It’s more than just a pretty picture; it’s a roadmap to engine timing and proper spark plug connection. We'll break down the key elements, explain how it all works, and even touch on some troubleshooting tips. Think of this as your guide to deciphering the secrets held within that distributor cap.

Purpose: Why You Need This Diagram

Why bother with a firing order distributor diagram? Simple. It's the key to:

- Correctly Wiring Your Distributor: Ensuring the right spark plug fires at the right time is paramount for optimal engine performance. A mistake here can lead to misfires, rough running, and even engine damage.

- Troubleshooting Misfires: A diagram allows you to quickly check if your spark plug wires are connected in the correct sequence. If you suspect a misfire, this is a logical first step.

- Engine Swaps & Modifications: Swapping engines or modifying your ignition system often requires understanding and potentially adjusting the firing order.

- Timing Adjustments: Understanding the firing order is essential when setting or adjusting ignition timing. Incorrect timing can severely impact performance and fuel economy.

- General Engine Diagnostics: Even if you're not planning major work, knowing how the firing order works can help you understand engine diagnostics better.

Basically, whether you're replacing spark plugs, diagnosing a performance issue, or rebuilding your engine, this diagram is an indispensable tool.

Key Specs and Main Parts

Before we get into the diagram itself, let's identify the key components we'll be looking at:

- Distributor Cap: This is the round (usually) cap that sits atop the distributor. It houses the terminals that connect to the spark plug wires.

- Distributor Rotor: Located inside the distributor cap, the rotor spins and makes contact with each terminal in sequence, distributing the high-voltage spark.

- Spark Plug Wires: These wires carry the high-voltage electricity from the distributor cap to the spark plugs.

- Spark Plugs: Located in the cylinder head, these plugs ignite the air-fuel mixture within the engine cylinders.

- Firing Order: This is the sequence in which the cylinders fire. It's specific to the engine type (e.g., inline-4, V6, V8). A typical firing order might be 1-3-4-2 for an inline-4, or 1-8-4-3-6-5-7-2 for a V8. It's crucial to have the correct firing order for your engine.

- Cylinder Numbers: Cylinders are numbered sequentially, usually starting from the front of the engine (opposite the flywheel end). The numbering system can vary based on engine configuration (inline vs. V-type).

These components work together to create the combustion necessary to move your car. The firing order is dictated by the engine's camshaft design and the position of the pistons within the cylinders.

Symbols: Deciphering the Diagram

A firing order distributor diagram isn’t complex, but understanding the conventions used is essential:

- Circles: Represent the distributor cap. Numbered around the circumference of the circle are the terminals corresponding to each cylinder.

- Numbers: Indicate the cylinder number. These are usually arranged in the same order as the firing order, but double-check to be sure!

- Lines/Arrows: Show the connection between the distributor cap terminal and the corresponding spark plug. The direction of the arrow (if present) may indicate the direction of electrical flow.

- Colors (if present): Some diagrams use colors to distinguish different cylinders or wiring circuits. A key should be included to explain the color coding.

- Rotor Position: Some diagrams might show the position of the rotor at a specific point in the firing sequence. This can be helpful when setting the distributor timing.

Always refer to the diagram specific to your engine. Generic diagrams might be helpful for understanding the concept, but the firing order and cylinder numbering are engine-specific.

How It Works: From Distributor to Combustion

Here's a simplified explanation of how the system works:

- The battery provides power to the ignition system.

- The ignition coil steps up the voltage to thousands of volts.

- The distributor rotor spins, driven by the engine's camshaft.

- As the rotor spins, it makes contact with each terminal inside the distributor cap in sequence.

- When the rotor aligns with a terminal, the high-voltage electricity flows through the spark plug wire connected to that terminal.

- The spark plug, located in the cylinder head, receives the high-voltage electricity.

- The electricity jumps the gap between the spark plug electrodes, creating a spark.

- This spark ignites the air-fuel mixture in the cylinder, causing an explosion that pushes the piston down and ultimately drives the crankshaft.

- This process repeats for each cylinder in the engine, according to the firing order.

The timing of the spark is crucial. It must occur at precisely the right moment in the piston's stroke for optimal power and efficiency. The distributor's position is adjustable to fine-tune the ignition timing.

Real-World Use: Basic Troubleshooting

Here are a few ways you can use a firing order diagram to troubleshoot engine problems:

- Misfire Diagnosis: If you suspect a misfire, check the spark plug wires against the diagram. Are they connected to the correct cylinders? Swapping two wires can cause a severe misfire.

- Rough Idle: A rough idle can be caused by incorrect ignition timing or a misfire. Use the diagram to confirm the spark plug wire connections and then check your timing.

- No-Start Condition: If the engine won't start, check the distributor cap and rotor for damage. Also, verify that the spark plug wires are properly seated in the distributor cap and on the spark plugs.

- Performance Issues: Poor acceleration, reduced fuel economy, or lack of power can sometimes be traced to incorrect ignition timing or spark plug wire issues. The diagram helps you systematically check for errors.

When troubleshooting, remember to check the basics first: spark plugs, wires, distributor cap, and rotor. A simple visual inspection can often reveal obvious problems.

Safety First: High-Voltage Considerations

Working with the ignition system involves high voltage. It's essential to take precautions:

- Never touch spark plug wires while the engine is running or the ignition is on. The voltage can be lethal.

- Use insulated tools when working on the ignition system.

- Disconnect the negative battery cable before working on any electrical components. This will prevent accidental shocks.

- Be especially careful in wet or damp conditions. Water increases the risk of electric shock.

Always prioritize safety when working on your vehicle.

We have a downloadable firing order distributor diagram file available for you to use. It is a general diagram, for specific diagrams, refer to the service manual for your vehicle.