4r100 Transmission Cooler Lines Diagram

Alright, let's dive into the 4R100 transmission cooler lines diagram. If you're tinkering with your Ford truck or SUV equipped with this robust transmission, understanding this system is crucial. Whether you're chasing a leak, planning an upgrade, or simply want to expand your automotive knowledge, this deep dive will arm you with the information you need. We're going to cover the purpose, specs, components, and troubleshooting, all presented in a way that's clear and practical. And, by the way, we have a downloadable diagram for you at the end, so you can follow along.

Purpose and Importance

Why bother understanding the 4R100 transmission cooler lines? The primary reason is to maintain the health and longevity of your transmission. Automatic transmissions generate a significant amount of heat. Excessive heat is the enemy of your transmission fluid, causing it to break down, lose its lubricating properties, and potentially leading to component failure. The transmission cooler and its associated lines are designed to dissipate this heat, keeping the fluid within a safe operating temperature range. A properly functioning cooler system is vital for reliable operation.

Knowing the layout of the cooler lines allows you to:

- Diagnose and repair leaks: Pinpointing the source of a transmission fluid leak can be tricky. The diagram helps you trace the lines and connections.

- Upgrade your cooling system: Thinking of adding an aftermarket cooler? Understanding the existing lines is paramount for proper installation.

- Perform routine maintenance: Regular inspection of the lines can catch potential problems before they lead to major repairs.

- Replace damaged lines: Whether it's rust, a rock strike, or other damage, knowing the line routing simplifies replacement.

- Understand transmission operation: The cooling system is an integral part of the transmission system as a whole.

Key Specs and Main Parts

The 4R100 transmission cooler system, while relatively simple in concept, comprises several key components:

- Transmission Out Port: This is where hot transmission fluid exits the transmission itself. Usually located on the side of the transmission case.

- Transmission In Port: This is where the cooled transmission fluid re-enters the transmission. Also typically located on the side of the transmission case.

- Cooler Lines: These are the metal (typically steel) or flexible (rubber) lines that carry the fluid between the transmission and the cooler(s). They are often pre-bent to follow a specific routing path.

- Factory Cooler (Radiator): The first stage of cooling usually involves a heat exchanger integrated into the radiator. The hot transmission fluid flows through this exchanger, transferring heat to the engine coolant.

- Auxiliary Cooler (Optional): Many trucks and SUVs are equipped with an auxiliary air-to-oil cooler, typically mounted in front of the radiator. This provides additional cooling capacity, especially important for towing or heavy-duty applications.

- Fittings and Connectors: These are the various threaded fittings, quick-connects, and hose clamps that connect the lines to the transmission, cooler(s), and each other. Common types include NPT (National Pipe Thread) and quick-disconnect fittings.

Line Sizes: The diameter of the cooler lines is important for maintaining adequate fluid flow. While there can be some variation, lines are typically 3/8" or 1/2" diameter. Using lines that are too small can restrict flow and lead to overheating.

Material: The lines themselves are usually made of steel tubing for the rigid sections and reinforced rubber hose for flexible connections. Steel lines are more durable and less prone to leaks, but can be more difficult to work with. Rubber hoses are easier to install and route, but can degrade over time.

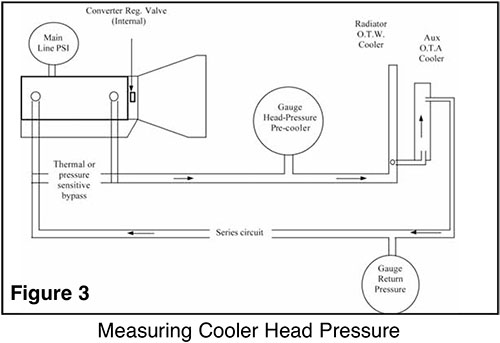

Understanding the Diagram: Symbols and Conventions

A typical 4R100 transmission cooler lines diagram will use specific symbols and conventions to represent the different components and their connections. Here's a breakdown:

- Solid Lines: These typically represent the primary cooler lines carrying transmission fluid.

- Dashed Lines: May indicate vacuum lines (if the transmission has a vacuum modulator, though the 4R100 is electronically controlled), or less critical connections.

- Arrows: Arrows indicate the direction of fluid flow. This is crucial for ensuring proper cooler installation.

- Different Colors: Sometimes, diagrams use different colors to distinguish between the "hot" line (from the transmission to the cooler) and the "cool" line (from the cooler back to the transmission).

- Rectangles: Often represent the coolers themselves (both the radiator cooler and the auxiliary cooler).

- Circles/Dots: Indicate connection points, such as where lines attach to fittings or components.

Interpreting the Flow: The diagram will show the fluid flowing out of the transmission, through the radiator cooler (if equipped), then potentially to an auxiliary cooler, and finally back to the transmission. Pay close attention to the direction of the arrows to ensure you understand the fluid path.

How It Works: The Cooling Process

The 4R100 transmission cooler system works on a simple principle: heat exchange. Here's the sequence:

- Hot transmission fluid exits the transmission under pressure.

- The fluid flows through the cooler lines to the radiator's internal transmission cooler. Here, heat is transferred from the transmission fluid to the engine coolant.

- In vehicles equipped with an auxiliary cooler, the fluid then flows to this cooler. The auxiliary cooler uses air flowing across its fins to dissipate heat, further reducing the fluid temperature.

- The cooled fluid then flows back to the transmission, lubricating and cooling internal components.

The thermostat in your cooling system, if functioning properly, helps maintain the optimal engine coolant temperature, which in turn aids the transmission cooling process. The auxiliary cooler is particularly effective when the vehicle is under heavy load or operating in hot weather, situations that generate more heat within the transmission.

Real-World Use: Troubleshooting and Maintenance

Here are some practical troubleshooting tips when dealing with the 4R100 transmission cooler lines:

- Leaks: This is the most common issue. Look for wet spots or drips around the lines, fittings, and coolers. Pay close attention to hose connections and areas where the lines may rub against other components. Use a UV dye and a blacklight to pinpoint elusive leaks.

- Overheating: If your transmission is running hot (indicated by a warning light or gauge), check the cooler lines for obstructions or damage. A collapsed line can restrict flow. Also, ensure the auxiliary cooler (if equipped) is free of debris and has good airflow.

- Fluid Contamination: If you suspect internal transmission damage, inspect the cooler lines for metal particles or other debris. Flushing the cooler lines after a major transmission repair is often recommended to prevent re-contamination.

- Line Corrosion: Steel cooler lines can rust over time, especially in areas with road salt. Inspect the lines regularly for signs of corrosion and replace them as needed.

Safety Considerations

Working with transmission cooler lines involves a few safety risks:

- Hot Fluid: Transmission fluid can be extremely hot, especially after the vehicle has been running. Allow the system to cool down before working on it to avoid burns.

- Pressurized System: Even after the engine is off, there may be residual pressure in the cooler lines. Loosen fittings slowly to relieve pressure.

- Eye Protection: Always wear safety glasses when working with fluids and compressed air.

- Flammable Fluid: Transmission fluid is flammable. Keep open flames away from the work area.

- Proper Disposal: Dispose of used transmission fluid properly according to local regulations. It's an environmental hazard.

The area where the cooler lines connect to the transmission itself is prone to leaks due to the heat cycles and vibrations. Be extra cautious when working in this area.

By understanding the 4R100 transmission cooler lines diagram, you'll be better equipped to maintain, troubleshoot, and repair this critical system. Remember to always prioritize safety and consult a qualified mechanic if you're unsure about any procedure.

As promised, we have the detailed 4R100 Transmission Cooler Lines Diagram available for you to download. You can access it here: [hyperlink to diagram file here - would be an actual link in a real implementation]. This diagram will serve as a great visual aid as you work on your truck.