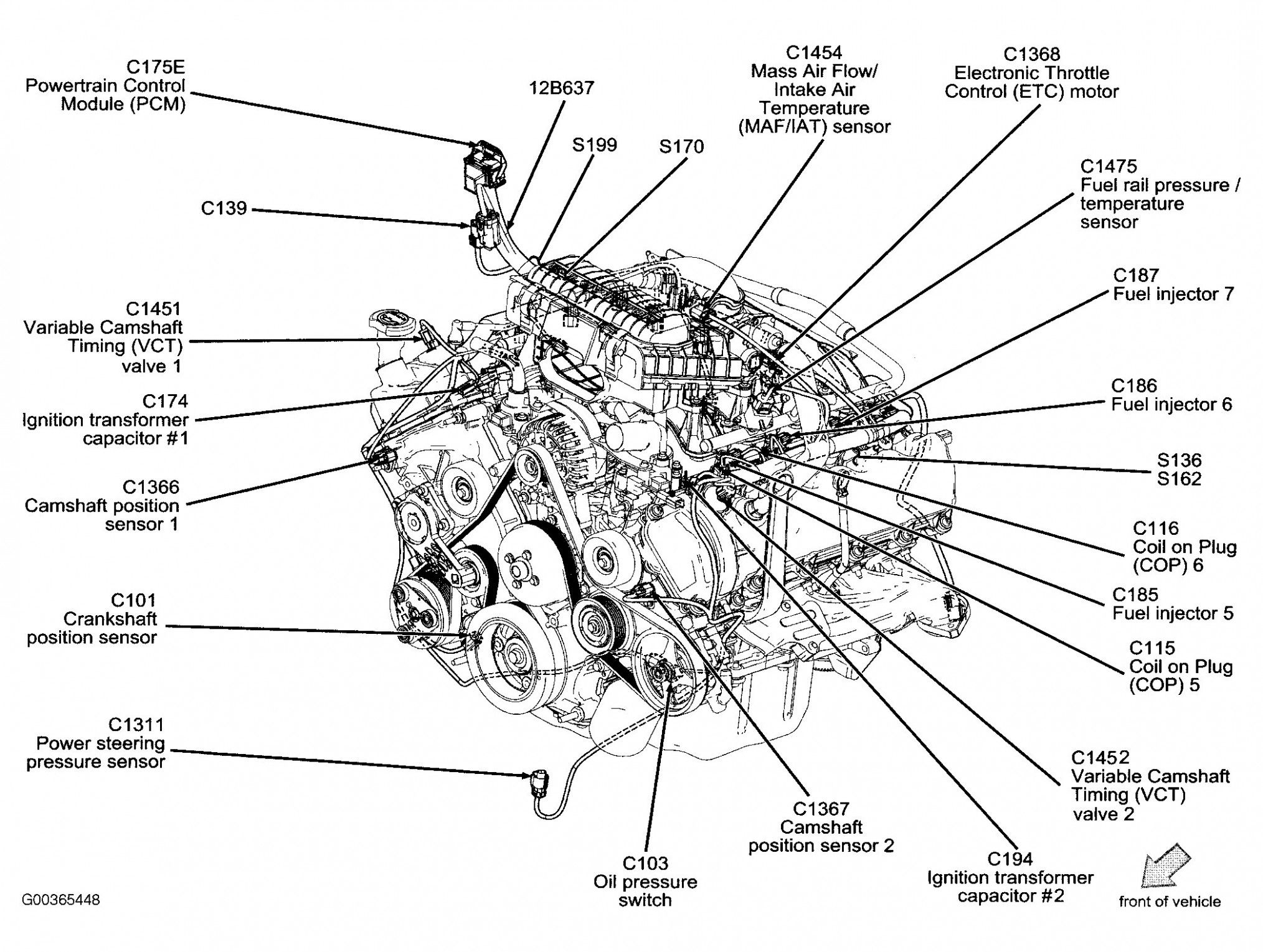

5.4 Triton V8 2006 Ford F150 5.4 Serpentine Belt Diagram

Alright, let's dive into the serpentine belt system for the 2006 Ford F-150 with the 5.4L Triton V8. This component is absolutely critical for your truck's operation, and understanding its layout – hence, the diagram – is essential for everything from routine maintenance to diagnosing more complex issues. This article will give you a solid understanding of the 5.4L Triton serpentine belt diagram, empowering you to tackle DIY projects with confidence.

Why Understanding the Serpentine Belt Diagram Matters

Think of the serpentine belt as the orchestra conductor of your engine's accessories. It's a single, continuous belt that snakes around various pulleys, transferring power from the crankshaft to essential components. Without a properly functioning serpentine belt, you're looking at a cascade of problems.

Having the diagram handy is invaluable for:

- Belt Replacement: Obvious, right? When the belt cracks, frays, or stretches, you need to replace it. The diagram ensures you route the new belt correctly. A misrouted belt can lead to accessory failure and even engine damage.

- Accessory Diagnosis: If your power steering, air conditioning, or alternator stops working, the belt is a prime suspect. The diagram helps you identify which accessory is driven by the belt and trace the power path.

- Tensioner/Idler Pulley Issues: Noisy or wobbly pulleys can cause belt slippage and premature wear. The diagram helps you locate these components for inspection and replacement.

- General Engine Understanding: Familiarizing yourself with the serpentine belt system gives you a better understanding of how your engine's accessories are powered.

Key Specs and Main Parts of the 5.4L Triton Serpentine System

Before we get into the diagram itself, let's identify the key players in this system:

- Crankshaft Pulley (Crank Pulley): This is the driving force. It's connected directly to the engine's crankshaft and provides the rotational power for the entire system.

- Alternator Pulley: The alternator generates electricity to keep your battery charged and power the electrical system.

- Power Steering Pump Pulley: Provides hydraulic pressure for power-assisted steering.

- Air Conditioning Compressor Pulley: Drives the compressor, which is the heart of your air conditioning system.

- Water Pump Pulley: Circulates coolant throughout the engine to prevent overheating.

- Tensioner Pulley: This spring-loaded pulley maintains the proper tension on the serpentine belt. Proper tension is crucial for preventing slippage and ensuring optimal accessory performance. This is a critical part, because too much tension can damage accessories, and too little leads to slippage and loss of power.

- Idler Pulley(s): Smooth, non-driven pulleys that guide the belt around the various components and maintain the correct wrap angle. They don't drive any accessories; they simply redirect the belt's path.

- Serpentine Belt: The actual belt made of rubber compound (typically EPDM – Ethylene Propylene Diene Monomer) that transmits power. The length and number of ribs are specific to the 5.4L Triton engine.

Typical Belt Length: While it can vary slightly depending on manufacturer, the belt length is usually around 96-98 inches. Always verify the correct part number for your specific application.

Decoding the Serpentine Belt Diagram: Symbols and Lines

A serpentine belt diagram isn't just a random drawing; it's a symbolic representation of the system's layout. Here's how to interpret the common symbols:

- Solid Lines: These represent the path of the outer surface of the serpentine belt. This is the side of the belt that makes contact with the smooth pulleys (idler pulleys, tensioner pulley, and the *back* of the water pump pulley).

- Dashed Lines: These usually represent the *inner*, ribbed side of the belt contacting the grooved pulleys (crankshaft, alternator, power steering pump, AC compressor). Sometimes, these are represented simply by the pulley being depicted in profile showing the grooves.

- Pulleys: Each pulley is represented by a circle. Larger circles usually indicate larger pulleys (like the crankshaft pulley). The specific accessory (alternator, AC compressor, etc.) will be labeled near the pulley.

- Direction Arrows: These indicate the direction of rotation for each pulley. This is crucial for understanding how the belt drives each accessory.

- Tensioner Symbol: The tensioner pulley is often represented with a spring symbol or an arrow indicating the direction of its spring-loaded movement.

Important Note: Diagrams can vary slightly in their presentation, but the basic principles remain the same. Focus on understanding the belt path and the location of each accessory.

How the Serpentine Belt System Works

The engine's crankshaft provides the initial rotational force. This force is transferred to the crankshaft pulley, which then drives the serpentine belt. The belt, in turn, wraps around the other pulleys, transferring power to the accessories. The tensioner pulley maintains the proper belt tension, preventing slippage and ensuring efficient power transfer. The belt snakes around the pulleys in a specific sequence, which is dictated by the engine's design and the placement of the accessories.

The wrap angle – the amount of contact the belt makes with each pulley – is critical. Insufficient wrap angle can lead to slippage, especially on high-demand accessories like the AC compressor. This is why idler pulleys are used; they increase the wrap angle on certain pulleys.

Real-World Use: Basic Troubleshooting Tips

Here's how you can use the serpentine belt diagram for basic troubleshooting:

- Squealing Noise: A common symptom of a slipping serpentine belt. Check the belt tension, look for cracks or glazing on the belt surface, and inspect the pulleys for signs of wear or misalignment. A failing tensioner is often the culprit.

- Accessory Failure: If an accessory stops working (e.g., no power steering), check the belt path to ensure the belt is still properly routed around that accessory's pulley. Also, check the belt for breakage. The diagram will quickly confirm if the belt drives that component.

- Visual Inspection: Regularly inspect the belt for cracks, frays, missing ribs, or oil contamination. Any of these signs indicates the need for replacement. Compare the belt's path to the diagram to ensure it's routed correctly.

- Tensioner Issues: A tensioner that's bouncing excessively or making noise is a sign of a problem. A failing tensioner can lead to belt slippage and premature wear.

Safety First: Risky Components and Procedures

Working on the serpentine belt system involves some risks. Keep these safety points in mind:

- Engine Off: Never work on the serpentine belt system with the engine running. This is incredibly dangerous and can result in serious injury.

- Hot Engine: Allow the engine to cool down completely before working on the belt. Components can be very hot and cause burns.

- Fan Blades: Be extremely careful around the radiator fan. Even with the engine off, some fans can still spin for a short period due to inertia.

- Proper Tools: Use the correct tools for the job, especially when releasing the tension on the tensioner pulley. Using the wrong tool can damage the tensioner or cause injury.

- Eye Protection: Always wear safety glasses when working under the hood.

The tensioner pulley stores significant spring energy. Releasing it without proper technique can cause the wrench to slip and potentially cause injury. Be mindful and in control when maneuvering it to release the serpentine belt.

Now that you are familiar with the serpentine belt diagram and system, you can use this information when performing work on your F-150. We have the file for the 2006 Ford F150 5.4 Serpentine Belt Diagram, and it is available to download. Happy wrenching!