Air Ride Switch Box Wiring Diagram

Alright, let's dive into the world of air ride switch box wiring diagrams. Whether you're tackling a repair, upgrading your existing system, or just aiming to understand how your air suspension works, this guide will break down the intricacies of a typical air ride switch box wiring setup. We'll cover everything from the purpose of the diagram to troubleshooting common issues. Consider this your go-to resource for navigating the electrifying world of air suspension controls.

Purpose of Understanding Air Ride Switch Box Wiring Diagrams

Why bother understanding this diagram? Simply put, it's the roadmap to your air suspension's control system. Without it, you're blindly poking around with wires, which is a recipe for disaster. A clear diagram lets you:

- Troubleshoot problems efficiently: Quickly identify faulty wiring, short circuits, or malfunctioning components.

- Perform repairs accurately: Ensure you're connecting the right wires to the right terminals.

- Upgrade or modify your system safely: Understand how new components integrate with the existing wiring.

- Learn about air suspension systems: Gain a deeper understanding of how the entire system operates.

Ultimately, knowing how to read and interpret this diagram empowers you to maintain and improve your air ride system with confidence.

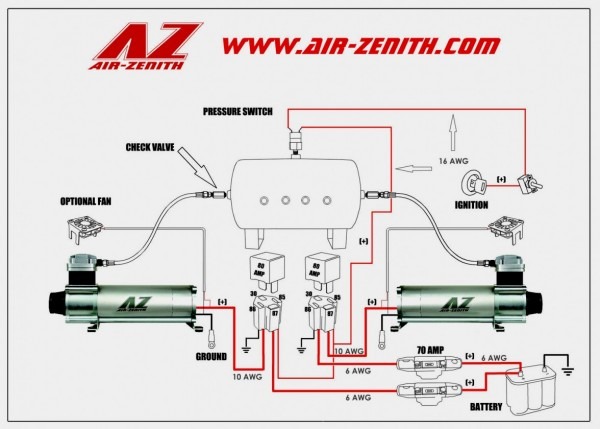

Key Specs and Main Parts of an Air Ride System

Before we jump into the wiring itself, let's identify the key components often controlled by the switch box. Knowing what these parts *do* will make understanding *how* they're wired much easier.

- Air Compressor: Provides the pressurized air that fills the air springs. It's often controlled by a relay triggered from the switch box.

- Air Tank: Stores the compressed air for immediate use.

- Air Springs (Bags): Replace the traditional coil springs and are inflated or deflated to adjust ride height.

- Solenoid Valves: Electrically controlled valves that allow air to flow into or out of the air springs. These are directly controlled by the switches in the switch box.

- Pressure Sensors (Transducers): Monitor the air pressure in the tank and/or air springs. Some systems have sensors feeding back to an ECU (electronic control unit) for advanced control.

- ECU (Optional): Some advanced systems use an ECU to manage the air suspension based on sensor input and driver preferences. Switch box signals may feed into this.

- Relays: Electrically operated switches that control high-current circuits, like the air compressor.

- Fuses: Essential safety devices that protect the wiring from overloads.

- Switch Box: Contains the switches that control the solenoid valves, and potentially the compressor relay.

The specification of each of these parts are important as well. The compressor needs to be compatible with the system pressure, the solenoid valve current needs to be within the specification of the switch you are using, and the fuse rating should match the circuit's maximum current draw.

Deciphering the Symbols in the Wiring Diagram

A wiring diagram is essentially a symbolic language. Here's a breakdown of common symbols you'll encounter:

- Solid Lines: Represent wires. Thicker lines often indicate wires carrying higher current.

- Dashed Lines: May represent ground connections, shielding, or wires running through a harness. Check the diagram's key.

- Circles: Can represent connectors, splices, or terminals. A filled circle often indicates a ground connection.

- Squares or Rectangles: Typically represent components like relays, switches, or sensors. Look inside for labels (e.g., "Relay," "Switch," "Sensor").

- Resistor Symbol (Zig-zag line): Indicates a resistor, used to limit current.

- Capacitor Symbol (Two parallel lines): Indicates a capacitor, used to store electrical energy.

- Solenoid Valve Symbol (Coil with a plunger): A coil with a line through the middle, moving with the magnetic field, represents a solenoid valve.

Colors: Wire colors are crucial! Standard color codes are often used (e.g., Red for power, Black for ground), but always verify with the diagram's legend. Common color codes include:

- Red: +12V Power

- Black: Ground

- Blue, Green, Yellow, White: Signal wires to solenoid valves, sensors, etc.

Icons: Icons represent the individual switches. A simple toggle switch will usually be displayed with a single pole single throw (SPST) or single pole double throw (SPDT) graphical representation. More complex rocker switches will show multiple throws to represent multiple solenoids that will be opened at once.

Always refer to the diagram's legend or key to understand the specific symbols and color codes used.

How an Air Ride Switch Box Wiring Works

The basic principle is simple: the switches in the switch box act as on/off controls for the solenoid valves. When a switch is flipped, it completes a circuit, sending power to the corresponding solenoid valve. This energizes the solenoid, opening the valve and allowing air to flow into or out of the air spring connected to it. Here's a typical scenario:

- Power Source: The switch box receives power from the vehicle's electrical system (usually the +12V battery).

- Switches: Each switch controls a specific solenoid valve (or a set of valves for front/rear control).

- Solenoid Activation: When a switch is turned on, it sends +12V to the solenoid valve's coil.

- Valve Opens: The energized coil creates a magnetic field that pulls the valve open.

- Airflow: With the valve open, air flows either *into* the air spring (to raise the vehicle) or *out* of the air spring (to lower the vehicle).

- Grounding: The solenoid valve needs a ground connection to complete the circuit. Typically, the solenoid valve's other wire is connected to the chassis ground.

The compressor is often controlled by the switch box. Typically a relay is used to switch the higher current needed for the compressor. A low current signal from the switch box will energize the relay, which then allows current from the battery to power the compressor.

Real-World Use: Basic Troubleshooting Tips

Okay, your air suspension isn't working as expected. Time to put your diagram to work. Here are a few common problems and how to troubleshoot them using the wiring diagram:

- No response from a particular air spring: Use the diagram to trace the wiring from the switch to the solenoid valve. Check for loose connections, broken wires, or a blown fuse. Test the solenoid valve itself for continuity (using a multimeter) to see if it's faulty.

- Air compressor not turning on: Check the fuse for the compressor. If the fuse is good, trace the wiring from the switch box to the compressor relay. Test the relay to see if it's working correctly. Use a multimeter to check for voltage at the compressor when the relay *should* be activated.

- System inflating/deflating on its own: This could indicate a short circuit in the wiring, a faulty solenoid valve that's sticking open, or a malfunctioning pressure sensor. Carefully inspect the wiring for any signs of damage or corrosion.

- Blown Fuses: Repeatedly blown fuses indicate a short circuit. Find the affected circuit on the diagram and inspect the wiring for damage or exposed wires touching the chassis.

Important: Use a multimeter to check for voltage and continuity when troubleshooting. Always disconnect the power source before working on the wiring.

Safety First: Highlighting Risky Components

Air suspension systems involve both electrical and pneumatic components, so safety is paramount. Here are a few key safety considerations:

- High Voltage Components: While the switch box itself operates on 12V, other components, like the air compressor, can draw significant current. Always disconnect the power source (usually the battery) before working on the wiring.

- Compressed Air: Air tanks store air at high pressure (often 150-200 PSI). Never attempt to disassemble or modify an air tank without depressurizing it first. Use appropriate safety glasses when working with compressed air.

- Short Circuits: Short circuits can cause fires and damage your vehicle's electrical system. Always use properly rated fuses and inspect wiring for damage or corrosion.

- Relays: Relays switch large current and should be handled with care. An improperly rated relay or a faulty relay can lead to overheating and potentially a fire.

Always consult the manufacturer's instructions and safety guidelines before working on your air suspension system.

That covers the fundamentals of air ride switch box wiring diagrams. Remember to always prioritize safety and take your time to understand the system before making any modifications or repairs. Good luck, and happy wiring!