Atv Diagram What Wires Go To The Starter Solenoid

Alright, let's dive into the starter solenoid wiring on your ATV. Understanding this circuit is crucial for everything from basic repairs to more advanced troubleshooting and even electrical modifications. A clear atv diagram detailing solenoid wiring is an invaluable tool, and in this guide, we'll break down exactly what those wires are and where they go. Knowing this stuff can save you a ton of money on mechanic bills and give you a much deeper understanding of how your ATV's electrical system works.

Purpose and Why This Diagram Matters

Why bother learning about the starter solenoid wiring diagram? Simple: it empowers you to diagnose and fix starting problems yourself. Maybe your ATV cranks slowly, doesn't crank at all, or makes a clicking sound but does nothing. These are all common symptoms pointing to issues in the starter circuit. A solid understanding of the wiring allows you to pinpoint the problem area, whether it's a faulty solenoid, a bad connection, or a damaged wire. Beyond repairs, knowing the diagram allows you to safely add accessories or modify your electrical system without risking damage to critical components.

Key Specs and Main Parts

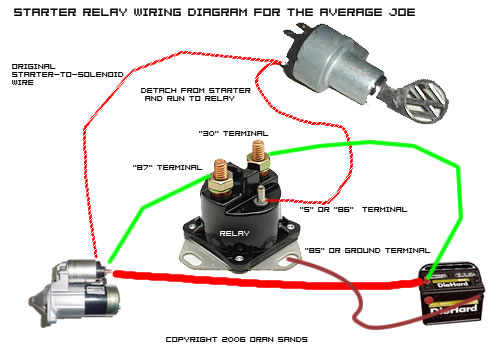

The starter solenoid is essentially a heavy-duty relay. Its job is to use a small electrical current from the ignition switch to switch on a much larger current from the battery to the starter motor. This is necessary because the starter motor draws a significant amount of amperage, far more than a typical ignition switch can handle. Here are the key components involved:

- Battery: The power source for the entire electrical system. Provides the high amperage needed for the starter motor.

- Ignition Switch: The switch that initiates the starting sequence. Sends a low-amperage signal to the starter solenoid.

- Starter Solenoid: The electromagnetic switch that connects the battery to the starter motor when energized.

- Starter Motor: The electric motor that physically turns the engine over, initiating the combustion process.

- Ground Connection: A crucial connection that provides a return path for the electrical current, ensuring a complete circuit.

- Wiring Harness: The collection of wires and connectors that interconnect all components.

Typical ATVs use a 12-volt electrical system. Wire gauges (thickness) are important. The wires running from the battery to the solenoid and from the solenoid to the starter are typically much thicker (e.g., 8-gauge or even 6-gauge) because they carry high current. The wire running from the ignition switch to the solenoid is much thinner (e.g., 16-gauge or 18-gauge) because it only carries a small control current.

Symbols – Lines, Colors, and Icons

Understanding the symbols on an ATV wiring diagram is essential. Here’s a breakdown of common elements:

- Lines: Lines represent wires. The thickness of the line sometimes (but not always) indicates the wire gauge.

- Colors: Each wire has a specific color. This is crucial for tracing wires and ensuring you're working with the correct circuit. Common colors include red (positive), black (ground), and various other colors like blue, green, yellow, and white for specific functions.

- Icons: Icons represent components. A battery is usually depicted as a series of alternating long and short lines. The starter solenoid is often shown as a rectangle with a coil symbol inside. The starter motor is represented by a stylized motor symbol.

- Ground Symbol: The ground symbol (often a series of stacked horizontal lines or an inverted triangle) indicates the connection point to the vehicle's frame or chassis, providing a return path for the current.

- Connectors: Connectors are depicted as circles, squares, or other shapes where wires join.

Color codes are your best friend. Always refer to the wiring diagram for your specific ATV model to ensure you're identifying the correct wires. Never assume wire colors are universal across all ATVs.

How It Works

The starting circuit works like this:

- When you turn the ignition key to the "start" position, a small current flows from the battery, through the ignition switch, and to the starter solenoid.

- This small current energizes the solenoid's internal coil.

- When the coil is energized, it creates an electromagnetic field.

- This electromagnetic field pulls a plunger (a movable core) inside the solenoid.

- The plunger connects two heavy-duty contacts inside the solenoid, completing a high-current circuit.

- This high-current circuit allows the full power of the battery to flow directly to the starter motor.

- The starter motor then spins, turning the engine over.

- Once the engine starts, you release the key from the "start" position.

- This de-energizes the solenoid, disconnecting the battery from the starter motor.

The solenoid acts as a gatekeeper, controlling the flow of high current to the starter motor based on the signal from the ignition switch.

Real-World Use – Basic Troubleshooting Tips

Here are some basic troubleshooting tips based on understanding the starter solenoid wiring:

- No Cranking, No Clicking: Check the battery voltage. Is it fully charged? Check the main fuses. Are any blown? Use a multimeter to check for voltage at the solenoid's control wire (the wire coming from the ignition switch) when the key is in the "start" position. If there's no voltage, the problem lies in the ignition switch or the wiring leading to it.

- Clicking Sound, No Cranking: This often indicates a weak battery, a corroded connection, or a faulty solenoid. Clean the battery terminals and check the battery voltage under load (while trying to crank). If the battery is good, use a multimeter to check for voltage at the starter motor terminal on the solenoid when the key is in the "start" position. If there's voltage there, the problem is likely the starter motor itself. If there's no voltage, the solenoid is likely faulty.

- Slow Cranking: Could be a weak battery, corroded connections, or a failing starter motor. Check the battery's state of charge. Clean and tighten all connections in the starting circuit, including the ground connection to the frame.

Remember to always disconnect the negative battery terminal before working on the electrical system to prevent accidental shorts.

Safety – Highlight Risky Components

The battery and the high-current wires running to and from the starter solenoid are potentially dangerous. Short-circuiting these wires can cause sparks, fires, and even battery explosions. Always use caution when working in this area.

- Battery: Always disconnect the negative terminal first and reconnect it last. Wear eye protection when working with batteries.

- High-Current Wires: Avoid touching these wires with metal tools while the battery is connected. Ensure the wires are properly insulated and protected from chafing.

- Solenoid Terminals: Be careful when testing the solenoid terminals with a multimeter. Accidental shorts can damage the solenoid or other components.

Never bypass the solenoid by directly connecting the battery to the starter motor unless you know exactly what you're doing. This can be extremely dangerous and can damage the starter motor or other electrical components.

In summary, understanding the ATV starter solenoid wiring diagram is essential for anyone looking to maintain, repair, or modify their ATV's electrical system. By understanding the purpose of each component, the wiring symbols, and the basic troubleshooting steps, you can confidently diagnose and fix starting problems. Always prioritize safety and consult a qualified mechanic if you are unsure about any aspect of the repair.

We have access to detailed ATV wiring diagrams. Contact us to download the specific diagram for *your* ATV model to ensure accurate and safe repairs!