Carburetor 2 Cycle Engine Fuel Line Diagram

So, you're diving into the fascinating world of 2-cycle engines, specifically focusing on the fuel line setup for those carburetors? Excellent! Understanding the fuel line diagram is absolutely crucial for everything from basic maintenance to advanced modifications. This article isn't just about memorizing a picture; it's about equipping you with the knowledge to diagnose problems, perform repairs confidently, and truly understand how your engine breathes.

Why Bother with a Fuel Line Diagram?

Let's face it, 2-cycle engines are known for their simplicity and power-to-weight ratio. But even simple systems can become confusing when things go wrong. A clear fuel line diagram is your roadmap to:

- Troubleshooting: Quickly identify leaks, clogs, or incorrect connections that lead to poor performance or engine failure.

- Repairs: Properly replace fuel lines, filters, and other components without guessing.

- Maintenance: Ensure the fuel system is properly primed and vented for optimal operation.

- Modifications: Safely and effectively modify the fuel system for increased performance. Thinking about bigger jets? You need to understand the existing system first!

- Learning: Deepen your understanding of how a 2-cycle engine works and interacts with its fuel system.

Key Specs and Main Parts of a 2-Cycle Fuel System

Before we dive into the diagram itself, let's review the core components you'll typically find in a 2-cycle engine's fuel system:

- Fuel Tank: Holds the premixed fuel and oil. The ratio is crucial (e.g., 50:1) for proper lubrication.

- Fuel Cap with Vent: Allows air to enter the tank as fuel is consumed. A blocked vent can cause a vacuum and fuel starvation.

- Fuel Line(s): Flexible hoses that transport fuel from the tank to the carburetor. Usually made of specialized fuel-resistant materials.

- Fuel Filter: Traps debris before it reaches the carburetor. A clogged filter is a common cause of engine problems.

- Fuel Primer Bulb (if equipped): A small hand-operated pump that draws fuel from the tank and primes the carburetor for easier starting.

- Carburetor: The heart of the fuel system. It mixes fuel and air in the correct proportions for combustion. The Venturi effect is a key principle here.

- Fuel Pump (Diaphragm Type - often integrated into the carburetor): Many small 2-stroke engines utilize the crankcase vacuum to actuate a diaphragm pump that draws fuel from the tank.

- Needle Valve and Seat: Controls the flow of fuel into the carburetor's float bowl based on the float level.

- Jets (Main Jet, Idle Jet): Calibrated orifices that meter the amount of fuel delivered to the engine at different throttle settings.

- Float Bowl: A reservoir that holds a small supply of fuel to ensure a consistent fuel level for the carburetor.

Decoding the Fuel Line Diagram: Symbols and Conventions

A fuel line diagram uses standard symbols to represent the different components and connections in the fuel system. Here's a breakdown:

- Solid Lines: Represent fuel lines. The thickness may indicate the diameter of the hose, though that's not always consistent.

- Dashed Lines: Often represent vacuum lines or vent lines. These are critical for proper carburetor function.

- Arrows: Indicate the direction of fuel flow. Pay close attention to these!

- Circles/Squares with Letters: Represent specific components (e.g., "T" for tank, "F" for filter, "C" for carburetor). The specific letters will vary depending on the diagram.

- Color Coding (if present): Some diagrams use color to differentiate fuel lines from vacuum lines or to highlight specific circuits (e.g., primer circuit).

Important: Always refer to the specific legend or key accompanying the diagram to understand the exact meaning of each symbol.

How It Works: Fuel Flow Through a 2-Cycle Engine

Understanding the fuel flow is crucial for effective troubleshooting. Here's a simplified overview:

- Fuel Delivery: Fuel is drawn from the fuel tank, usually through a weighted pickup filter inside the tank.

- Filtering: The fuel passes through the fuel filter to remove any contaminants.

- Carburetor Entry: The fuel enters the carburetor, either directly into the float bowl (if present) or through the fuel pump diaphragm chamber.

- Fuel Metering: The carburetor mixes the fuel with air, using jets and needles to control the fuel-air ratio based on engine speed and load.

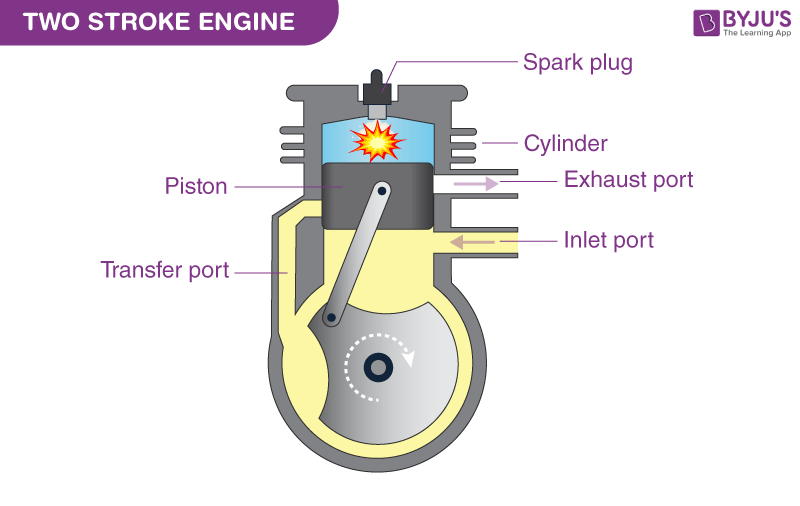

- Mixture Delivery: The fuel-air mixture is drawn into the engine's cylinder during the intake stroke (via the crankcase in a typical 2-stroke design).

- Combustion: The mixture is compressed and ignited by the spark plug, producing power.

The pulse from the crankcase pressure variations drives the fuel pump in many smaller 2-stroke engines. This is a critical element in the fuel delivery system.

Real-World Use: Basic Troubleshooting Tips

Here are a few common problems you might encounter and how the fuel line diagram can help:

- Engine Won't Start: Check for fuel flow. Is the fuel line cracked or disconnected? Is the fuel filter clogged? Is the fuel tank vent blocked? Use the diagram to trace the fuel path from the tank to the carburetor.

- Engine Runs Poorly (Surging, Stalling): Air leaks in the fuel lines or vacuum lines can cause erratic running. Carefully inspect all lines for cracks or loose connections. The diagram will show you which lines are vacuum lines.

- Fuel Leakage: Identify the source of the leak. Is it a cracked fuel line, a leaking fuel filter, or a problem with the carburetor? The diagram will help you isolate the leaking component.

- Primer Bulb Not Working: Check the primer bulb itself for cracks or damage. Also, ensure the fuel lines connected to the primer bulb are properly connected and not blocked. The diagram will show the correct orientation.

Safety First: Handling Fuel and Fuel Systems

Working with fuel systems requires caution. Remember these safety tips:

- Fuel is Flammable: Work in a well-ventilated area away from open flames or sparks.

- Fuel Can Irritate Skin: Wear gloves to protect your skin.

- Dispose of Fuel Properly: Never pour fuel down the drain or into the environment.

- Disconnect the Spark Plug: Before working on the fuel system, disconnect the spark plug to prevent accidental starting.

- Fuel Lines Can Be Under Pressure: Relieve pressure before disconnecting fuel lines to avoid fuel spraying.

The carburetor itself can be tricky. Be careful when disassembling it, as it contains small, easily lost parts. Always consult the service manual for specific instructions.

This overview provides a solid foundation for understanding 2-cycle engine fuel line diagrams. Remember to always consult the specific diagram for your engine model for the most accurate information. With this knowledge, you'll be well-equipped to tackle fuel system maintenance and repairs with confidence.

We've got a sample fuel line diagram available for download. It's a great resource to use alongside this article as you familiarize yourself with these systems.