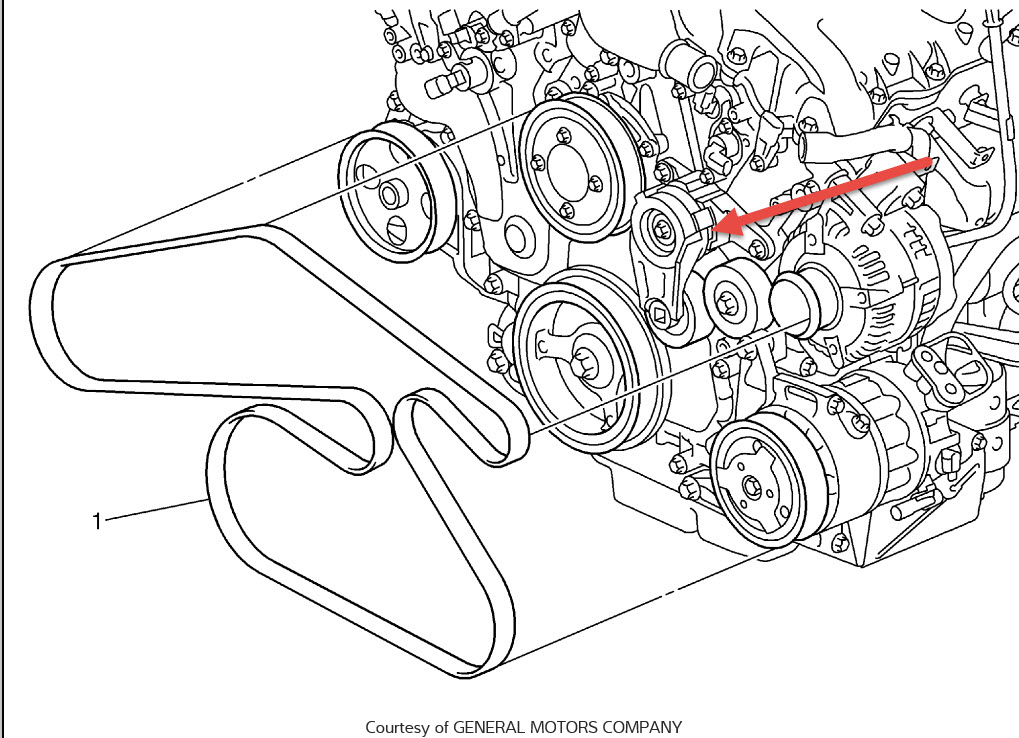

Chevrolet Equinox 2012 Chevy Equinox 3.0 Serpentine Belt Diagram

Alright, let's dive into the serpentine belt diagram for your 2012 Chevy Equinox with the 3.0L V6. This isn't just some pretty picture; it's your roadmap to keeping your engine running smoothly and avoiding a roadside breakdown. We're going to cover the diagram in detail, from why it's important to how to use it for troubleshooting. Think of me as your experienced mechanic walking you through the process.

Why You Need This Diagram

The serpentine belt is the unsung hero of your engine bay. It's a single, continuous belt that snakes around multiple pulleys, driving essential components like the alternator (which charges your battery), the power steering pump (making steering easier), the air conditioning compressor (keeping you cool), and sometimes the water pump (cooling the engine). A broken serpentine belt means *none* of these systems will function, leaving you stranded. A diagram is crucial for:

- Replacement: Absolutely essential when replacing a worn or broken serpentine belt. Incorrect routing will damage the belt and potentially the driven components.

- Troubleshooting: If you hear a squealing noise from the engine, a visual inspection using the diagram can help you pinpoint the potential source of the problem.

- General Maintenance: Understanding the belt's path allows you to inspect it for wear and tear, cracks, or fraying more effectively.

- Learning: Even if you don't need it right now, understanding how the belt system works improves your overall automotive knowledge.

Key Specs and Main Parts

For the 2012 Chevy Equinox 3.0L, the serpentine belt routing is fairly standardized, but variations can exist. Always double-check your specific vehicle's diagram. The main components you'll encounter in the diagram (and in your engine bay) are:

- Crankshaft Pulley (or Harmonic Balancer): This is the main drive pulley, connected directly to the engine's crankshaft. Everything starts here.

- Alternator Pulley: Driven by the belt to generate electricity.

- Power Steering Pump Pulley: Powers the hydraulic power steering system.

- Air Conditioning (A/C) Compressor Pulley: Engages and disengages to power the A/C system.

- Water Pump Pulley: Circulates coolant through the engine to prevent overheating. Note: On some engines, the water pump might be driven by the timing belt instead. On the 3.0L Equinox, it is driven by the Serpentine belt.

- Idler Pulley(s): These are smooth, unpowered pulleys used to guide the belt and maintain proper tension.

- Tensioner Pulley: A spring-loaded pulley that automatically maintains the correct tension on the serpentine belt. This is a *critical* component. A failing tensioner can lead to belt slippage, noise, and premature belt wear.

The belt itself is a multi-ribbed belt, typically made of a synthetic rubber compound. The ribs increase the surface area of contact with the pulleys, improving grip and reducing slippage. The *specific belt length is crucial*; use the correct replacement belt for your vehicle.

Understanding the Symbols in the Diagram

The serpentine belt diagram isn't just a picture; it's a technical drawing with specific symbols to convey information. Here's what to look for:

- Solid Lines: Represent the main path of the serpentine belt. The thicker the line, generally the more significant the belt segment.

- Dotted Lines: Sometimes used to indicate the *backside* of the belt contacting a pulley. This is important because the ribbed side typically drives the components, while the smooth backside can be used for idler pulleys.

- Arrows: Show the direction of belt rotation. This is essential for understanding how each component is driven.

- Component Labels: Abbreviations or acronyms identify each pulley and its associated component (e.g., ALT for alternator, P/S for power steering, A/C for air conditioning).

- Routing Arrows/Diagrams on the Tensioner: Some vehicles have a small diagram or arrow on the tensioner itself, indicating the correct belt routing. Always double-check!

While colors aren't typically used in basic serpentine belt diagrams, some enhanced diagrams might use different colors to highlight specific sections of the belt or different systems. Pay attention to any legend or key that accompanies the diagram.

How It Works: Power Transmission

The principle is simple: the engine's crankshaft rotates, driving the crankshaft pulley. This pulley, in turn, drives the serpentine belt. The belt wraps around the other pulleys, transferring the rotational force to each component. The tensioner pulley ensures that the belt remains tight against all the pulleys, preventing slippage. Without proper tension, the belt will slip, resulting in reduced performance of the driven components (e.g., weak alternator output, poor A/C performance, difficult steering).

The order in which the belt wraps around the pulleys is important. The diagram shows the optimal route, ensuring that the belt has enough contact with each pulley to transmit sufficient power. A common mistake is to route the belt incorrectly, which can cause it to rub against other components, slip excessively, or even jump off the pulleys.

Real-World Use: Troubleshooting Tips

Here are some common issues you might encounter and how the serpentine belt diagram can help:

- Squealing Noise: Often indicates a slipping belt. Check the belt's tension and condition. Use the diagram to ensure the belt is routed correctly and that the tensioner is functioning properly. If the tensioner is bouncing excessively, it's likely worn and needs replacement.

- Cracked or Frayed Belt: Replace the belt immediately. Use the diagram to ensure the new belt is routed correctly.

- Component Failure: If a component, such as the alternator or power steering pump, fails, it might put excessive strain on the belt, causing it to wear prematurely or break. Diagnose and repair the underlying component issue *before* replacing the belt.

- Belt Jumping Off: Incorrect belt routing is the most common cause. Refer to the diagram to verify the belt's path. A worn tensioner or a damaged pulley can also cause the belt to jump off.

When inspecting the belt, pay close attention to the ribs. Look for cracks, missing chunks, or excessive wear. Also, check the pulleys for any signs of damage or misalignment. A misaligned pulley can cause the belt to wear unevenly and eventually fail.

Safety First: Handle with Care

Working on the serpentine belt system can be dangerous if you're not careful. Here's what to keep in mind:

- Disconnect the Battery: Always disconnect the negative battery cable before working on any electrical components, including the alternator.

- Hot Engine: Never work on the serpentine belt system when the engine is hot. Allow the engine to cool completely before proceeding.

- Moving Parts: Keep your hands and clothing away from moving parts. Even with the engine off, the belt can snap back unexpectedly when releasing the tensioner.

- Tensioner Spring: The tensioner has a strong spring that can cause injury if released suddenly. Use the correct tool to release the tension gradually.

- Eye Protection: Wear safety glasses to protect your eyes from debris.

The alternator and A/C compressor can store electrical charge even after the battery is disconnected. Be careful not to short them out.

Remember, if you're not comfortable working on the serpentine belt system yourself, it's always best to consult a qualified mechanic. They have the experience and tools to do the job safely and correctly.

We have the serpentine belt diagram file available for you. Download it and keep it handy for future reference. It's your guide to a well-maintained and reliably running 2012 Chevy Equinox 3.0L.