Chrysler 300 Serpentine Belt Diagram

Let's talk about the serpentine belt diagram for your Chrysler 300. This isn't just some pretty picture; it's a vital tool for anyone tackling engine repairs, preventative maintenance, or even just trying to understand how the accessories on your 300 are driven. Think of it as the roadmap to your engine's accessory drive system. Having a clear understanding of it can save you time, money, and a whole lot of frustration.

Purpose of the Serpentine Belt Diagram

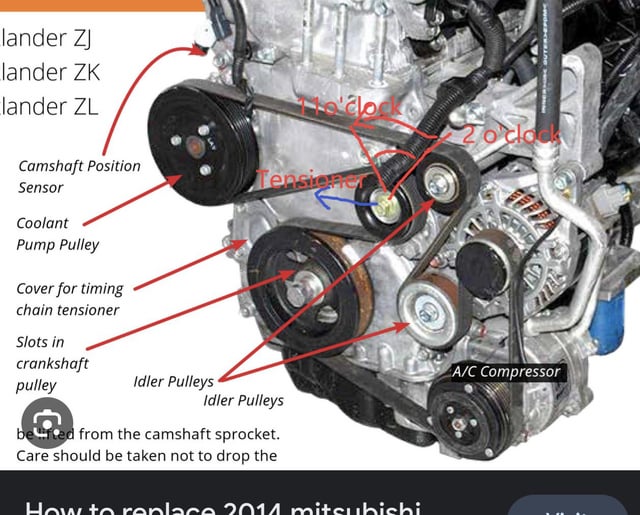

The serpentine belt diagram serves several critical purposes. Primarily, it shows you the exact routing of the serpentine belt around the various pulleys connected to your engine. Why is this important? Because if you ever need to replace the belt – and you *will* at some point – you need to know the correct path to thread the new one. An incorrectly routed belt can lead to immediate failure, damage to accessories, and even engine overheating due to a non-functioning water pump.

Beyond replacement, the diagram helps with diagnosis. If you hear a squealing noise coming from under the hood, the diagram allows you to quickly identify which accessory – power steering pump, alternator, AC compressor, etc. – might be the culprit, or if the idler or tensioner pulleys are the source of the noise. It's also invaluable for confirming proper belt tension and identifying any misaligned pulleys.

Key Specs and Main Parts in a Chrysler 300 Serpentine Belt System

The serpentine belt system on your Chrysler 300, regardless of engine (though the diagrams do vary slightly between engine sizes and model years, which is why having the right one is crucial!), consists of several key components:

- Serpentine Belt: The main drive belt itself. Typically made of reinforced rubber, it's responsible for transferring rotational force from the crankshaft to the accessories. Its length and width (specified in millimeters, e.g., 6PK2250, where 6PK indicates 6 ribs and 2250 is the length in mm) are critical.

- Crankshaft Pulley (Harmonic Balancer): This is the pulley driven directly by the engine's crankshaft. It's also known as the harmonic balancer because it dampens torsional vibrations from the engine.

- Alternator Pulley: Drives the alternator, which charges the battery and powers the electrical system.

- Power Steering Pump Pulley: Drives the power steering pump, providing hydraulic assistance for steering.

- Air Conditioning (AC) Compressor Pulley: Drives the AC compressor, responsible for cooling the cabin.

- Water Pump Pulley: Drives the water pump, which circulates coolant through the engine to prevent overheating.

- Idler Pulley(s): Smooth pulleys that help guide the belt and maintain optimal wrap angle on other pulleys. They are not driven by any accessory.

- Tensioner Pulley: A spring-loaded pulley that maintains consistent tension on the serpentine belt. This is crucial for proper accessory operation and preventing belt slippage. A worn tensioner can cause belt noise and reduced accessory performance.

Understanding Serpentine Belt Diagram Symbols

Serpentine belt diagrams use a standard set of symbols. Here's a breakdown:

- Solid Lines: Represent the *visible* portion of the serpentine belt.

- Dashed Lines: Represent the portion of the belt that runs *behind* other components or pulleys, making it hidden from direct view. This is essential for understanding the belt routing in three dimensions.

- Arrows: Indicate the direction of belt travel. Follow these arrows to understand how the belt loops around the various pulleys.

- Circles/Ovals: Represent the pulleys. The diagram will label each pulley (e.g., "ALT" for alternator, "P/S" for power steering).

- Small Circles (Often Shaded): Can represent idler pulleys.

- Spring Symbols: Near the tensioner pulley, indicating its spring-loaded nature.

- Numbers: Some diagrams might include numbered steps to illustrate the belt routing process, especially when special tools are required.

How the Serpentine Belt System Works

The serpentine belt system is relatively simple in concept. The crankshaft, driven by the engine's combustion, spins the crankshaft pulley. This rotation is then transferred to the serpentine belt. The belt, under tension maintained by the tensioner pulley, wraps around the various accessory pulleys, causing them to rotate. This rotation drives the accessories like the alternator, power steering pump, AC compressor, and water pump.

The tension on the belt is paramount. Too little tension, and the belt will slip, resulting in reduced performance from the accessories and a characteristic squealing noise. Too much tension, and it can prematurely wear out the belt, pulleys, and accessory bearings. The tensioner pulley is designed to automatically compensate for belt stretch and wear, maintaining the correct tension over the belt's lifespan. However, the tensioner itself can wear out and require replacement.

Real-World Use: Troubleshooting with the Diagram

Here are a few common troubleshooting scenarios where the serpentine belt diagram is invaluable:

- Squealing Noise: Use the diagram to identify which pulley is closest to the source of the noise. A bad bearing in that accessory or idler pulley is a likely culprit. Also, inspect the belt itself for cracks, glazing, or missing ribs.

- Accessory Failure: If your power steering suddenly stops working, or your AC isn't blowing cold, check the belt routing. Has the belt slipped off a pulley? Is the belt broken? The diagram helps you confirm the belt's integrity and proper routing.

- Battery Not Charging: If your battery isn't charging, the alternator might not be spinning. The diagram helps you verify that the belt is properly driving the alternator pulley.

- Overheating: A non-functioning water pump will lead to overheating. The diagram shows you how the water pump is driven by the serpentine belt. If the belt is broken or slipping on the water pump pulley, the engine will overheat.

Basic Troubleshooting Steps:

- Visually inspect the belt for cracks, wear, and proper tension.

- Check the pulleys for wobble or excessive play.

- Ensure the belt is routed correctly according to the diagram.

- Use a belt tension gauge (if available) to verify proper tension.

Safety Considerations

Working on the serpentine belt system can be dangerous. Here's what you need to know:

- Hot Engine: Never work on the serpentine belt system immediately after the engine has been running. Allow the engine to cool completely to prevent burns.

- Moving Parts: Never attempt to inspect or adjust the serpentine belt while the engine is running. The moving belt and pulleys can cause serious injury.

- Battery Disconnect: Disconnect the negative battery terminal before starting any work to prevent accidental electrical shorts.

- Sharp Tools: Be careful when using tools near the belt and pulleys. Avoid damaging the belt with sharp edges.

- Tensioner Spring: The tensioner pulley is spring-loaded and can snap back forcefully when released. Use the correct tool to relieve tension on the belt. Do not attempt to pry it with a screwdriver – you could damage it or injure yourself.

Specific Risky Components:

- Crankshaft Pulley: Be especially cautious around the crankshaft pulley. It rotates at high speed and can cause severe injury if you get your hands or clothing caught in it.

- Tensioner Pulley: As mentioned above, the spring-loaded tensioner can be dangerous if not handled properly.

Remember, if you're not comfortable working on the serpentine belt system yourself, it's always best to consult a qualified mechanic. This article is for informational purposes only and should not be considered a substitute for professional advice.

We have a downloadable, high-resolution serpentine belt diagram specifically for your Chrysler 300, covering various engine options and model years. This diagram will provide you with the precise routing information you need. Contact us to get the file.