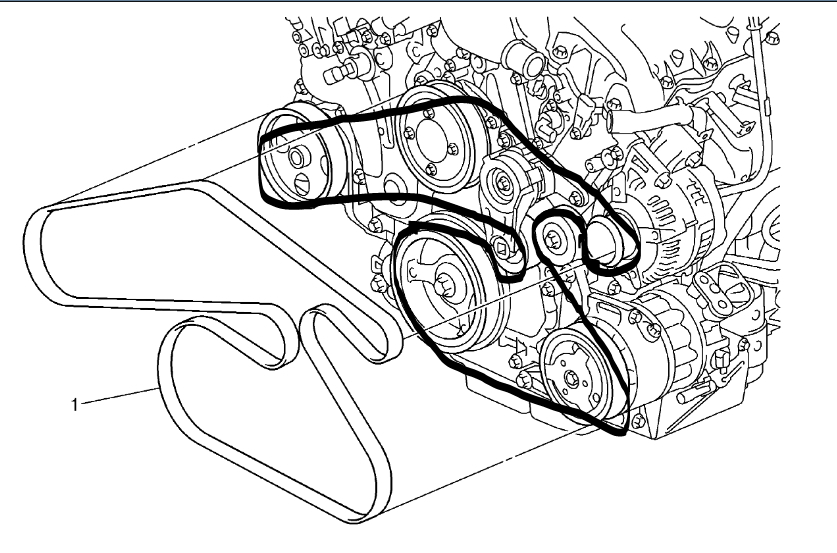

Chrysler 3.6 Serpentine Belt Diagram

The serpentine belt. It's a seemingly simple component, but its proper routing and tension are critical to the reliable operation of numerous vital systems in your Chrysler equipped with the ubiquitous 3.6L Pentastar V6 engine. Whether you're tackling a routine replacement, diagnosing a squealing belt, or just familiarizing yourself with your vehicle's layout, understanding the serpentine belt diagram is paramount. This article provides a detailed, technically-focused guide, empowering you to confidently navigate this essential aspect of your Chrysler's maintenance.

Purpose of Understanding the Serpentine Belt Diagram

Why bother learning about the serpentine belt diagram? The reasons are multifaceted:

- Repairs and Maintenance: The most obvious reason. Proper belt routing is essential after replacing the belt itself, or after performing any work that requires its removal (water pump, alternator, etc.). An incorrectly routed belt can lead to system failures and potentially catastrophic engine damage.

- Troubleshooting: A diagram helps you quickly identify the components driven by the belt. This aids in diagnosing problems such as a failing alternator (battery not charging), loss of power steering assist, or overheating due to a non-functioning water pump.

- Learning and Familiarization: Understanding the belt's path provides a deeper understanding of how your engine's accessory systems function and interact. This knowledge is invaluable for proactive maintenance and preventing future issues.

- Modifications and Upgrades: If you're considering modifications to your engine that affect the accessory drive (e.g., installing an underdrive pulley), you'll absolutely need to understand the belt routing and tensioning system.

Key Specs and Main Parts

Before diving into the diagram, let's review the key components and specifications associated with the 3.6L Pentastar serpentine belt:

- Belt Material: Typically EPDM (Ethylene Propylene Diene Monomer) rubber. This material offers excellent heat and ozone resistance.

- Belt Length: Varies slightly depending on the specific Chrysler model and year. It is crucial to use the correct belt length for your vehicle. Always consult your vehicle's service manual or a reputable parts supplier to determine the correct part number.

- Tensioner: An automatic spring-loaded tensioner maintains proper belt tension. Inspect the tensioner regularly for smooth operation and proper damping. A worn tensioner can cause belt slippage and noise.

- Idler Pulley(s): Smooth, ungrooved pulleys that guide the belt along its path. Inspect for smooth rotation and excessive play.

The main parts driven by the serpentine belt on the 3.6L Pentastar typically include:

- Crankshaft Pulley (Damper): The driving force of the entire system.

- Alternator: Provides electrical power to the vehicle.

- Water Pump: Circulates coolant to regulate engine temperature.

- Power Steering Pump: Provides hydraulic assistance for steering.

- Air Conditioning Compressor: Compresses refrigerant for the air conditioning system.

Symbols: Understanding Lines, Colors, and Icons

A serpentine belt diagram uses various symbols to represent the different components and their relationships. Here's a breakdown:

- Solid Line: Represents the path of the belt itself. The thickness of the line is typically uniform.

- Pulley Icons: Each pulley is depicted as a circle. The surface of the circle indicates the type of pulley.

- Grooved Pulley: A pulley with grooves indicates that the ribbed side of the belt contacts the pulley. These are typically used on the crankshaft, alternator, power steering pump, and A/C compressor.

- Smooth Pulley: A pulley with a smooth surface indicates that the back side of the belt contacts the pulley. These are typically idler pulleys and the tensioner pulley.

- Tensioner Icon: The tensioner is often represented with a pulley symbol and an adjacent arrow indicating the direction of the spring-loaded tension. Sometimes it has a small representation of a spring mechanism.

- Directional Arrows: Arrows along the belt path indicate the direction of belt travel. This is crucial for ensuring proper routing.

- Component Labels: Each component (alternator, water pump, etc.) is clearly labeled with its name or abbreviation.

How It Works: The Serpentine Belt System

The serpentine belt system is a relatively simple yet efficient design. The crankshaft pulley, driven by the engine's rotation, transfers power to the belt. The belt, in turn, drives all the accessory components. The automatic tensioner maintains the correct belt tension, preventing slippage and ensuring optimal performance of all driven components. The back of the belt makes contact with smooth pulleys, whereas the ribbed side of the belt makes contact with grooved pulleys. The belt weaves in and out, using the different surfaces to change the drive direction of the pulleys as needed. The entire system is designed to operate efficiently and reliably, but proper maintenance and timely replacement of worn components are essential.

Real-World Use: Basic Troubleshooting Tips

Here are some common issues you might encounter and how the serpentine belt diagram can help you troubleshoot:

- Squealing Belt: A common problem. Check the belt for cracks, wear, or glazing. A loose belt can also cause squealing. Use the diagram to visually inspect the belt's path and ensure it's properly seated on all pulleys. Also, check the tensioner for proper operation. If the tensioner arm is bouncing excessively, it may be worn or failing.

- Accessory Malfunction: If your alternator, power steering, or A/C is not functioning correctly, use the diagram to confirm that the belt is properly routed and driving the component. A slipped or broken belt will immediately disable the affected system.

- Overheating: A malfunctioning water pump can lead to overheating. Use the diagram to verify that the belt is driving the water pump correctly.

- Belt Jumping Off: This indicates a serious problem, such as a misaligned pulley or a failing tensioner. Carefully inspect all pulleys for damage or looseness. Consult the diagram to verify proper belt routing.

A Note About Belt Tension: While the automatic tensioner maintains tension, it's still a good idea to periodically check the belt's condition and the tensioner's operation. Excessive wear or slippage indicates a problem that needs to be addressed.

Safety: Highlight Risky Components

Working on the serpentine belt system involves several safety considerations:

- Engine Off: Always ensure the engine is turned off and the key is removed from the ignition before working on the serpentine belt.

- Hot Components: The engine and exhaust components can be extremely hot. Allow the engine to cool completely before working near these areas.

- Moving Parts: The serpentine belt and its associated components are moving parts. Never insert your hands or tools into the system while the engine is running.

- Tensioner Spring: The automatic tensioner contains a strong spring. Use appropriate tools to relieve the tension when removing or installing the belt. Never attempt to manually force the tensioner without the proper tools.

Important: Incorrect installation or improper handling of the serpentine belt system can result in serious injury or damage to your vehicle. If you are not comfortable performing this work yourself, consult a qualified mechanic.

By understanding the serpentine belt diagram and following safe practices, you can confidently maintain and troubleshoot this essential system in your Chrysler 3.6L Pentastar-equipped vehicle.

We have the file available with a detailed serpentine belt diagram for the Chrysler 3.6L engine. You can download it for closer study and real-world application.